Ceramic-based composite material thread machining method

A thread processing, ceramic-based technology, applied in the field of anti-oxidation, high temperature resistant fiber reinforced composite material thread processing, high strength, thread processing, can solve the problems of low thread life, poor thread quality, poor thread processing quality stability, etc. Achieve the effect of reducing density requirements and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

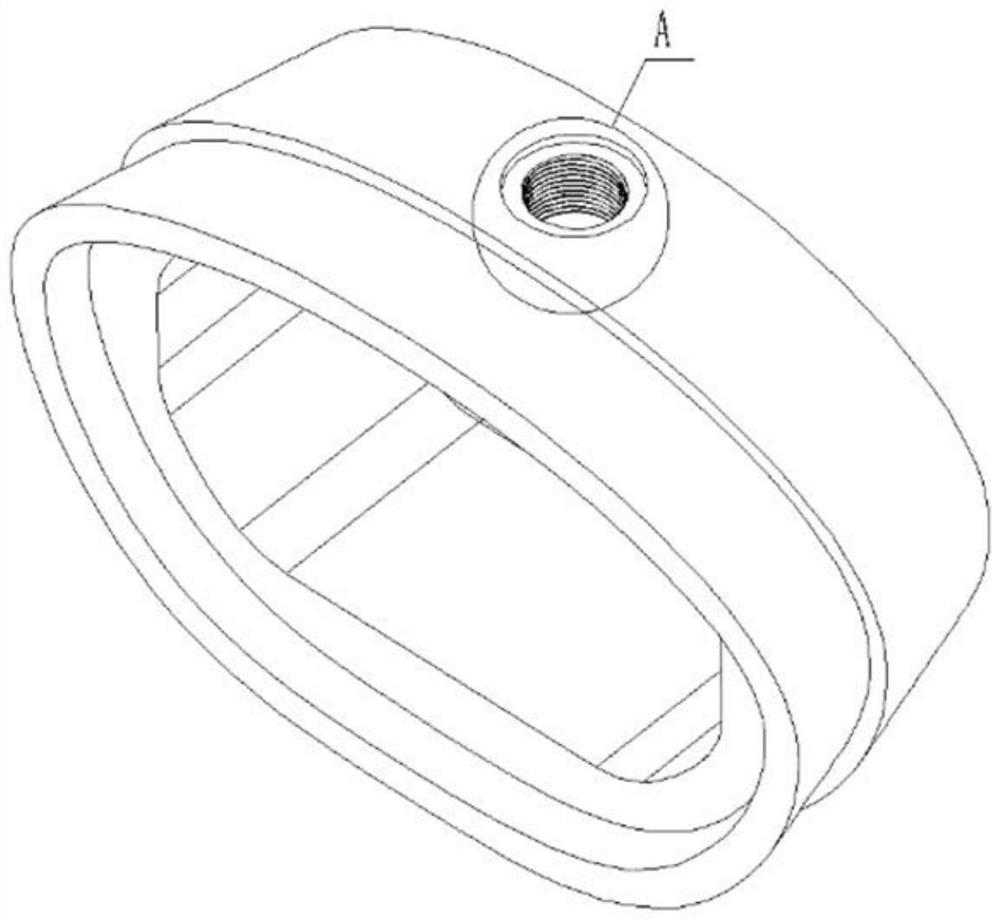

[0044] This embodiment takes the M10 screw hole machining thread of the modified ceramic-based composite part as an example, and the specific steps are as follows:

[0045] 1) Weigh rosin, alum and boron carbide powder in a mass ratio of 5:3:1.3;

[0046] 2) Add rosin and alum into a clean crucible container, heat until the rosin and alum are completely melted, then add boron nitride powder, and heat while stirring until it is a viscous glue, and the total mass of glue is 40±0.1 g.

[0047] 3) Polishing, cleaning and drying the bottom hole of the M10 thread of the modified ceramic-based composite parts that need to be prepared;

[0048] When cleaning, first use clean water to rinse the surface of the modified ceramic-based composite parts M10 and other redundant objects, and then use ultrasonic cleaning. Dry at ±5°C for 4h, then drop to room temperature and take out.

[0049] 4) Apply glue to the thread parts to be processed of the modified ceramic-based composite parts M10...

Embodiment 2

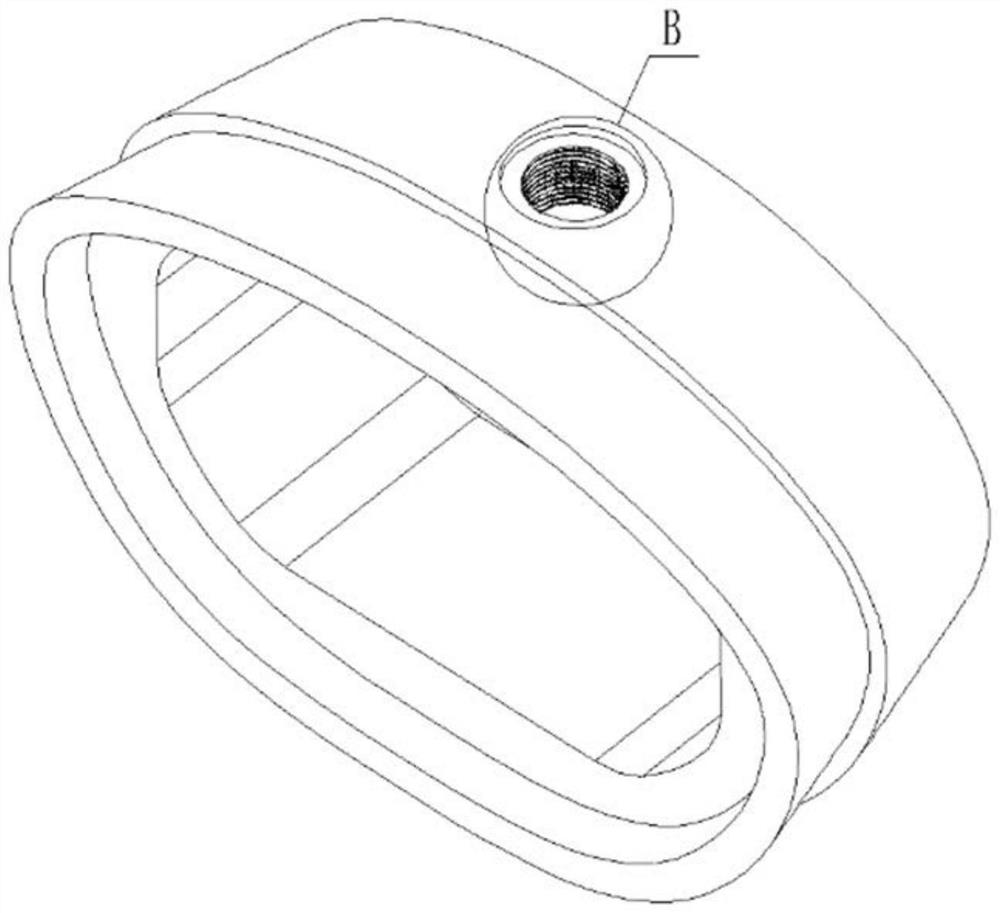

[0059] In this embodiment, the thread processing of the ceramic-based composite nut is taken as an example, and the specific steps are as follows:

[0060] 1) Weigh rosin, alum and boron carbide powder in a mass ratio of 4.5:2:1.5;

[0061] 2) Add rosin and alum into a clean crucible container, heat until the rosin and alum are completely melted, then add boron nitride powder, and heat while stirring, until it is a viscous glue, and the total mass of glue is 53.4±0.1 g.

[0062] 3) Polishing, cleaning and drying the threaded bottom hole of the ceramic-based composite nut that needs to be threaded;

[0063] When cleaning, first use clean water to rinse off the redundant objects such as floating ash on the surface of the ceramic-based composite nut, then use ultrasonic cleaning, ultrasonic temperature 25±5℃, ultrasonic cleaning time 50min, and then put it in an oven at a temperature of 145±5℃ The drying time was 3.5h, and it was taken out at room temperature.

[0064] 4) Appl...

Embodiment 3

[0074] In this embodiment, the thread processing of ceramic-based composite M8 countersunk head screws is used as an example, and the specific steps are as follows:

[0075] 1) Weigh rosin, alum and boron carbide powder according to the mass ratio of 4.8:2.5:1.0;

[0076] 2) Add rosin and alum into a clean crucible container, heat until the rosin and alum are completely melted, then add boron nitride powder, and heat while stirring until it is a viscous glue, and the total mass of glue is 40.5±0.1 g.

[0077] 3) Polishing, cleaning and drying the ceramic-based composite M8 countersunk head screws that need to prepare threads;

[0078] When cleaning, first use clean water to rinse the surface of the ceramic-based composite M8 countersunk head screws and other redundant objects, and then use ultrasonic cleaning, ultrasonic temperature 25 ± 5 ℃, ultrasonic cleaning time 30min, and then put it in an oven, at a temperature of 175 ± Dry at 5°C for 3h, then drop to room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com