Sodium lanthanum molybdate-zinc molybdate europium-doped spherical red light emitting material and preparation method thereof

A luminescent material, sodium lanthanum molybdate technology, applied in luminescent materials, chemical instruments and methods, climate sustainability, etc., can solve the problem of reducing light scattering, conversion efficiency is not as good as micron-sized phosphors, surface morphology light In order to achieve the effect of less equipment restrictions, suitable for popularization and use, and good shape control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

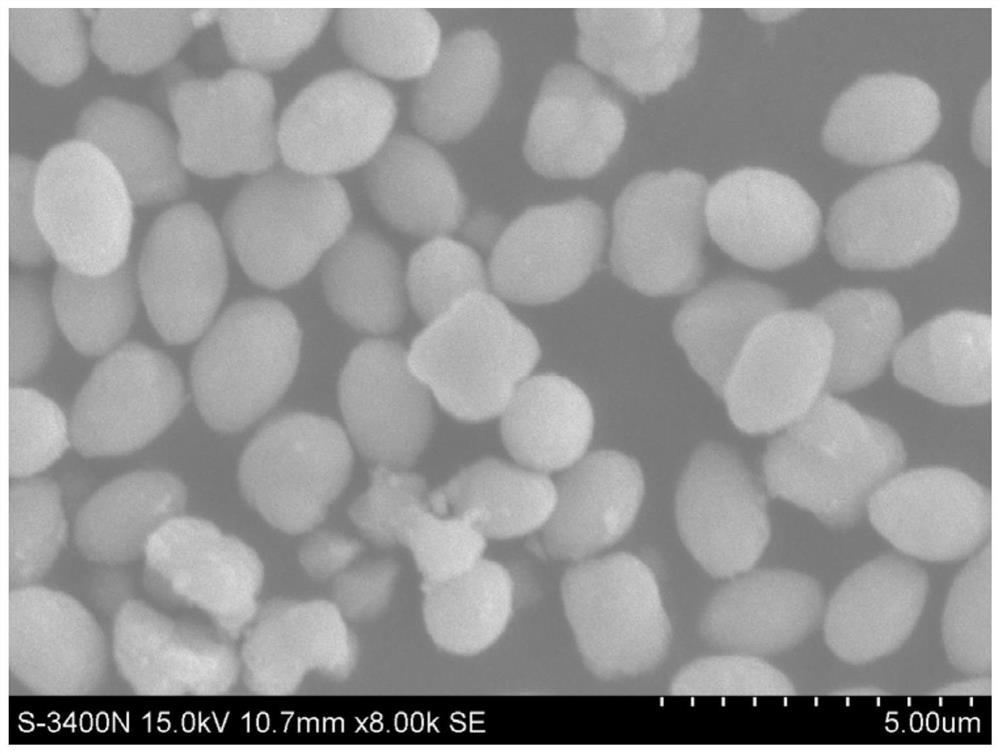

Embodiment 1

[0035] A kind of sodium lanthanum molybdate-zinc molybdate doped europium spherical red light emitting material, its chemical formula is NaLa 0.95 (MoO 4 ) 2 -ZnMoO 4 :0.05Eu 3+ .

[0036] The above-mentioned preparation method of sodium lanthanum molybdate-zinc molybdate doped europium spherical red light emitting material specifically comprises the following steps:

[0037] Add lanthanum oxide and europium oxide into a nitric acid solution with a concentration of 65%, and control the temperature to stir and dissolve in the range of 40 to 60 °C, respectively, to prepare a lanthanum nitrate solution with a concentration of 0.20±0.001mol / L and 0.02±0.001 mol / L. mol / L europium nitrate solution; dissolve sodium molybdate in deionized water to prepare a sodium molybdate solution with a concentration of 0.40±0.001mol / L.

[0038] Measure an appropriate amount of lanthanum nitrate solution and europium nitrate solution in a beaker, weigh an appropriate amount of zinc nitrate and...

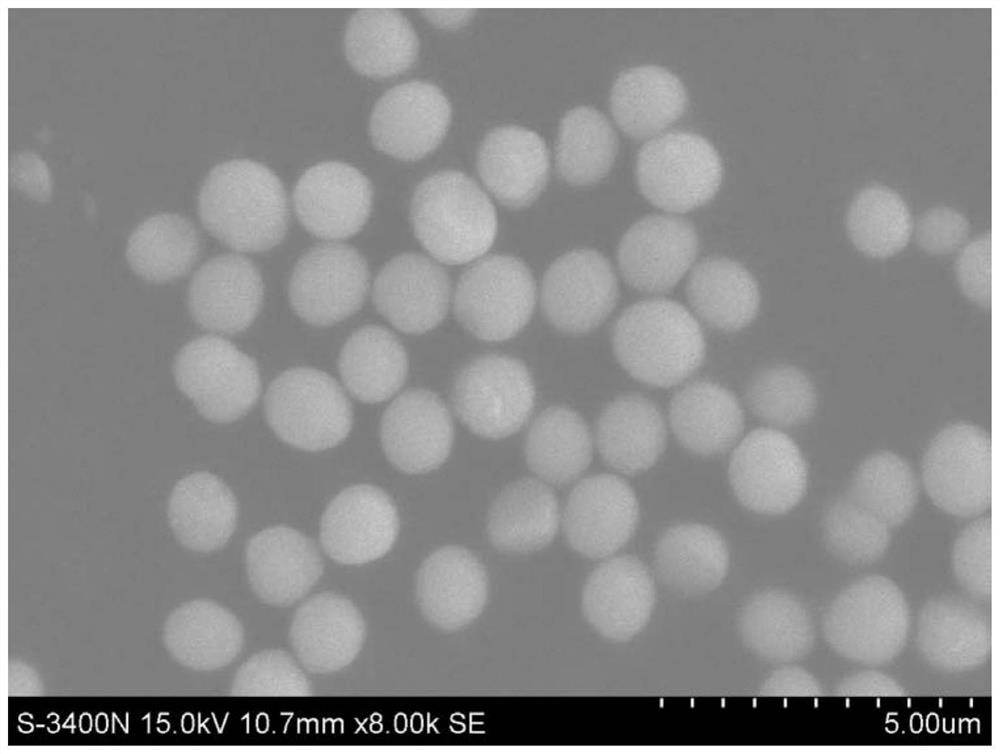

Embodiment 2

[0044] A kind of sodium lanthanum molybdate-zinc molybdate doped europium spherical red light emitting material, its chemical formula is NaLa 0.95 (MoO 4 ) 2 -ZnMoO 4 :0.05Eu 3+ .

[0045] The above-mentioned preparation method of sodium lanthanum molybdate-zinc molybdate doped europium spherical red light emitting material specifically comprises the following steps:

[0046] Add lanthanum oxide and europium oxide into a nitric acid solution with a concentration of 65%, and control the temperature to stir and dissolve in the range of 40 to 60 °C, respectively, to prepare a lanthanum nitrate solution with a concentration of 0.20±0.001mol / L and 0.02±0.001 mol / L. mol / L europium nitrate solution; dissolve sodium molybdate in deionized water to prepare a sodium molybdate solution with a concentration of 0.40±0.001mol / L.

[0047] Measure an appropriate amount of lanthanum nitrate solution and europium nitrate solution in a beaker, weigh an appropriate amount of zinc nitrate and...

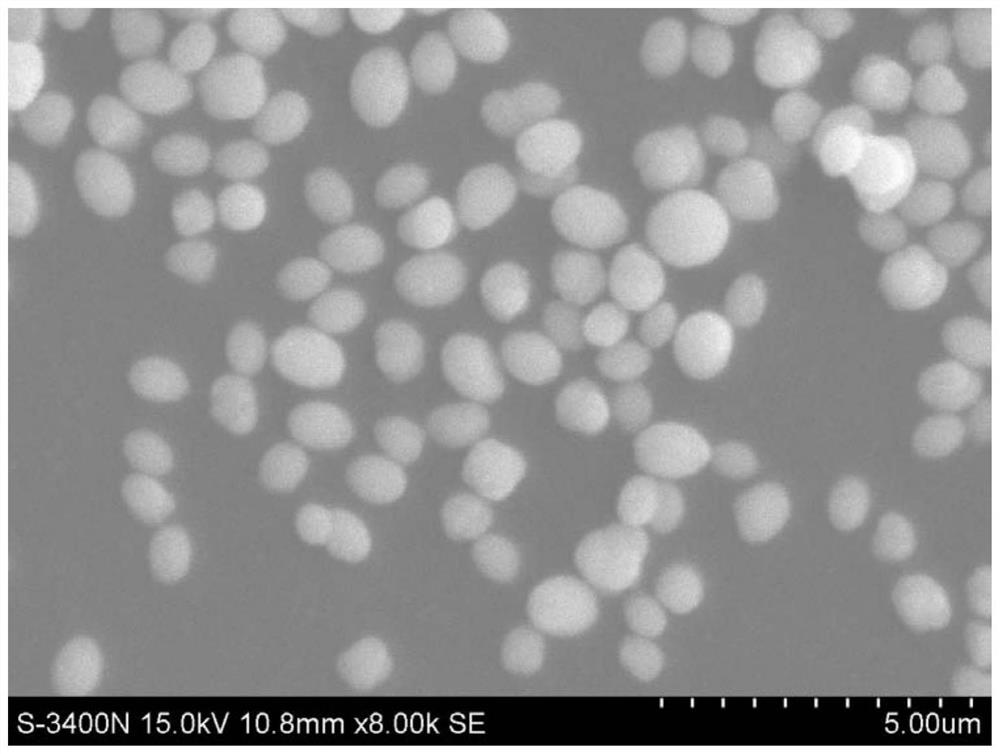

Embodiment 3

[0053] A kind of sodium lanthanum molybdate-zinc molybdate doped europium spherical red light emitting material, its chemical formula is NaLa 0.95 (MoO 4 ) 2 -ZnMoO 4 :0.05Eu 3+ .

[0054] The above-mentioned preparation method of sodium lanthanum molybdate-zinc molybdate doped europium spherical red light emitting material specifically comprises the following steps:

[0055] Add lanthanum oxide and europium oxide into a nitric acid solution with a concentration of 65%, and control the temperature to stir and dissolve in the range of 40 to 60 °C, respectively, to prepare a lanthanum nitrate solution with a concentration of 0.20±0.001mol / L and 0.02±0.001 mol / L. mol / L europium nitrate solution; dissolve sodium molybdate in deionized water to prepare a sodium molybdate solution with a concentration of 0.40±0.001mol / L.

[0056] Measure an appropriate amount of lanthanum nitrate solution and europium nitrate solution in a beaker, weigh an appropriate amount of zinc nitrate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com