Indium sulfate electrolyte and preparation method thereof

An indium sulfate and electrolyte technology, applied in the metallurgical field, can solve the problems of high cost, decreased indium output, inconvenient production, etc., and achieve the effects of low test condition requirements, high production efficiency and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

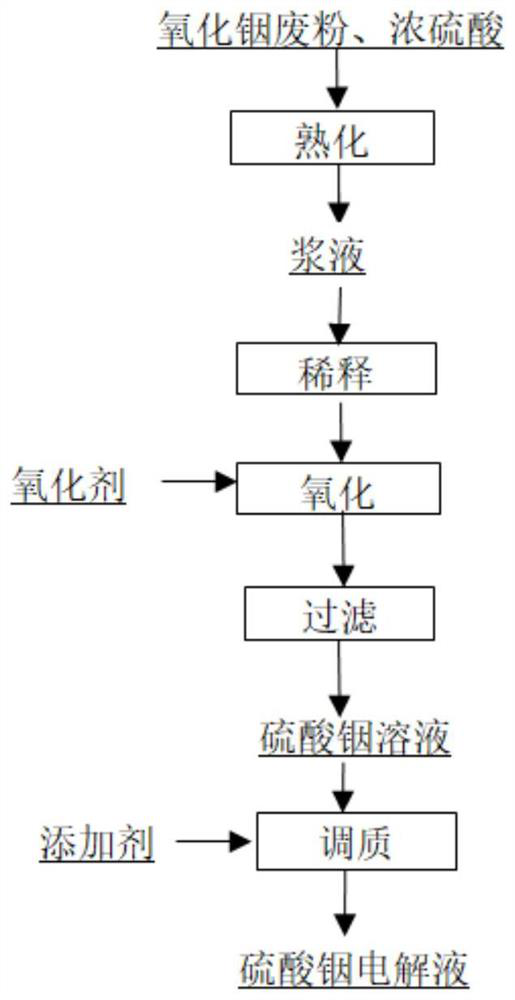

[0031] An embodiment of the indium sulfate electrolyte and its preparation method of the present invention, the preparation method is as follows figure 1 shown, including the following steps:

[0032] (1) Mix 100g of 99.99% indium oxide waste powder and 20mL of standard concentrated sulfuric acid solution in a ceramic crucible and stir evenly, place and mature for 5 hours, add 300mL of pure water to dilute, and then slowly drop 30mL of standard concentrated sulfuric acid solution to obtain solution A;

[0033] (2) adding 2% oxidant to solution A and heating to 40°C and stirring for 20h to obtain solution B; the oxidant is sodium chlorate;

[0034] (3) insert solution B into the granular activated carbon layer prepared by coconut shell and carry out filtration and separation treatment, after gained filtrate adds concentration 15% sodium carbonate solution to adjust pH to 1, adds sodium chloride and gelatin and stirs, to obtain final product The preparation period of the indium s...

Embodiment 2

[0037] An embodiment of the indium sulfate electrolyte and its preparation method of the present invention, the preparation method is as follows figure 1 shown, including the following steps:

[0038] (1) Mix 100g of 99.99% indium oxide waste powder and 30mL of standard concentrated sulfuric acid solution in a ceramic crucible and stir evenly, leave to mature for 3 hours, add 400mL of pure water to dilute, and then slowly drop 20mL of standard concentrated sulfuric acid solution to obtain solution A;

[0039] (2) adding 3% oxidant to solution A and heating to 60°C and stirring for 15h to obtain solution B; the oxidant is sodium hypochlorite;

[0040] (3) insert solution B into the granular activated carbon layer prepared by coconut shell and carry out filtration and separation treatment, after gained filtrate adds concentration 10% sodium carbonate solution to adjust pH to 1, adds sodium chloride and gelatin and stirs, to obtain final product The preparation period of the ind...

Embodiment 3

[0043] An embodiment of the indium sulfate electrolyte and its preparation method of the present invention, the preparation method is as follows figure 1 shown, including the following steps:

[0044] (1) Mix 100g of 99.99% indium oxide waste powder and 40mL of standard concentrated sulfuric acid solution in a ceramic crucible and stir evenly, leave to mature for 1 hour, add 500mL of pure water to dilute, and then slowly drop 10mL of standard concentrated sulfuric acid solution to obtain solution A;

[0045] (2) adding 5% oxidant to solution A and heating to 80°C and stirring for 10h to obtain solution B; the oxidant is hydrogen peroxide;

[0046] (3) insert solution B into the granular activated carbon layer prepared by coconut shell and carry out filtration and separation treatment, after gained filtrate adds concentration 15% sodium carbonate solution and adjusts pH to 2, adds sodium chloride and gelatin and stirs, to obtain final product The preparation period of the indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com