Process for treating sewage with zeolite filler in aerated biologic filter pool

A technology of aerated biological filter and filter material, which is applied in sustainable biological treatment, biological water/sewage treatment, aerobic process treatment and other directions, can solve the problems of reducing the effective utilization time of equipment, etc. Convenience and volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

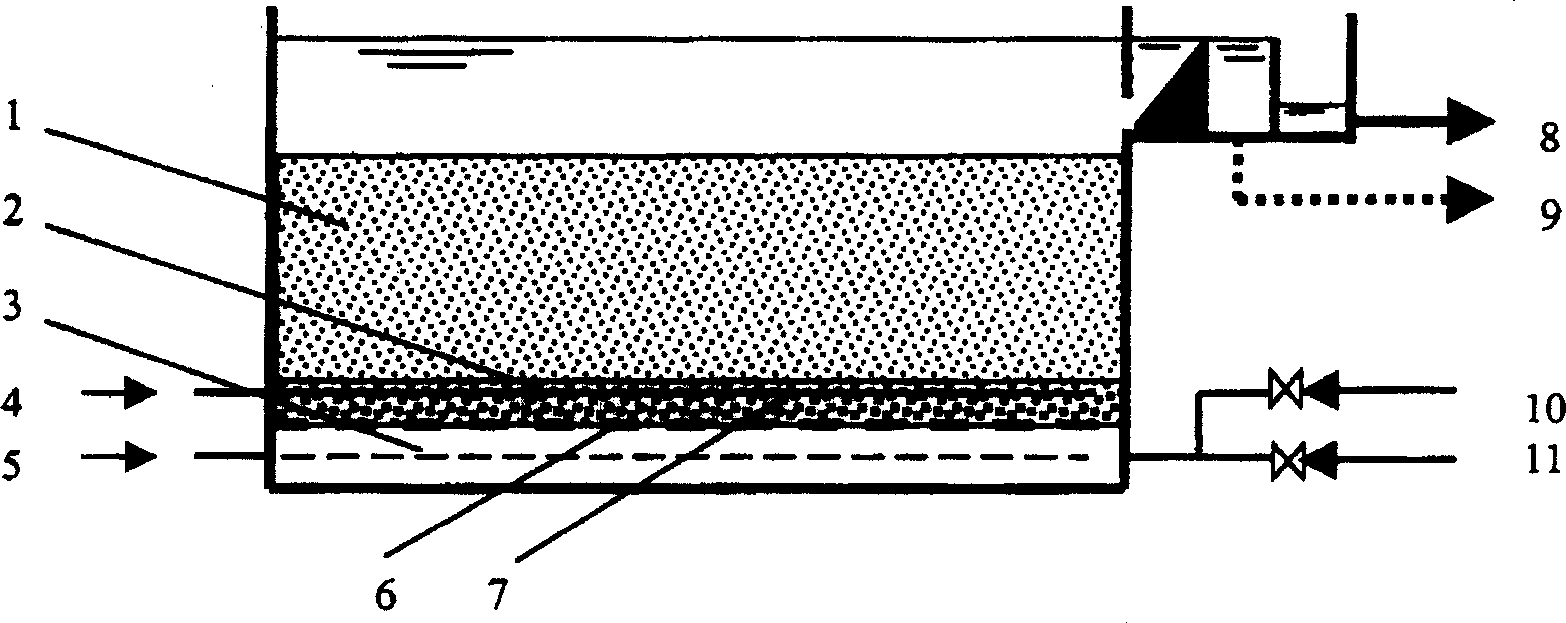

Image

Examples

Embodiment 1

[0023] Treatment of low-concentration domestic sewage: choose a particle size of 4-6 mm and a density of (1900-2100) kg / m 3 , the hardness is Mohs hardness 4~5, and the ammonia ion exchange capacity is (3~4)kg / m 3 . When the COD in the sewage is (80-120) mg / L, and the ammonia nitrogen is (10-15) mg / L, the water-air ratio is 1:2-1:3, the height of the filter material is (2-3) m, and the hydraulic load (2~4)m / h; this process adopts air-water combined backwashing method, and the air flushing intensity in the first stage is (15~18)L / (m 2 s), flushing time (3~7)min; second stage air flushing intensity (15~18)L / (m 2 s), the water flushing intensity is (10~12)L / (m 2 s), the flushing time is (10~15)min; the third stage water rinsing intensity is (10~12)L / (m 2 s), time (5-10) min. The removal rate of suspended solids is about 90%, the removal rate of COD is about 80%, and the removal rate of ammonia nitrogen is 80-90%.

Embodiment 2

[0025] Advanced treatment of domestic sewage: choose a particle size of (3-4) mm and a density of (2000-2200) kg / m 3 , the hardness is Mohs hardness 3~4, and the ammonia ion exchange capacity is (5~6)kg / m 3 . When the COD in the sewage is (40-90) mg / L, and the ammonia nitrogen is (15-40) mg / L, the water-air ratio is 1:1-1:2, and the hydraulic load is (4-6) m / h. The material height is (2-4) m. This process adopts the air-water combined backwash method, and the air flushing intensity in the first stage is (12~15)L / (m 2 s), flushing time (3~7)min; second stage gas flushing intensity (12~15)L / (m 2 s), the water flushing intensity is (8~10)L / (m 2 s), the flushing time is (10-20)min; the third-stage water rinsing intensity is (8-10)L / (m 2 s), time (5-10) min. The removal rate of suspended solids is about 90%, the removal rate of COD is about 70-80%, and the removal rate of ammonia nitrogen is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com