Acetic acid leakage type high-yield pyruvate bacterium and its breeding method and producing pyruvic acid by said bacterium via fermentation process

A technology of pyruvate and sodium acetate, applied in fermentation, fungi, etc., can solve the problems of high ethanol and low yield of pyruvate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

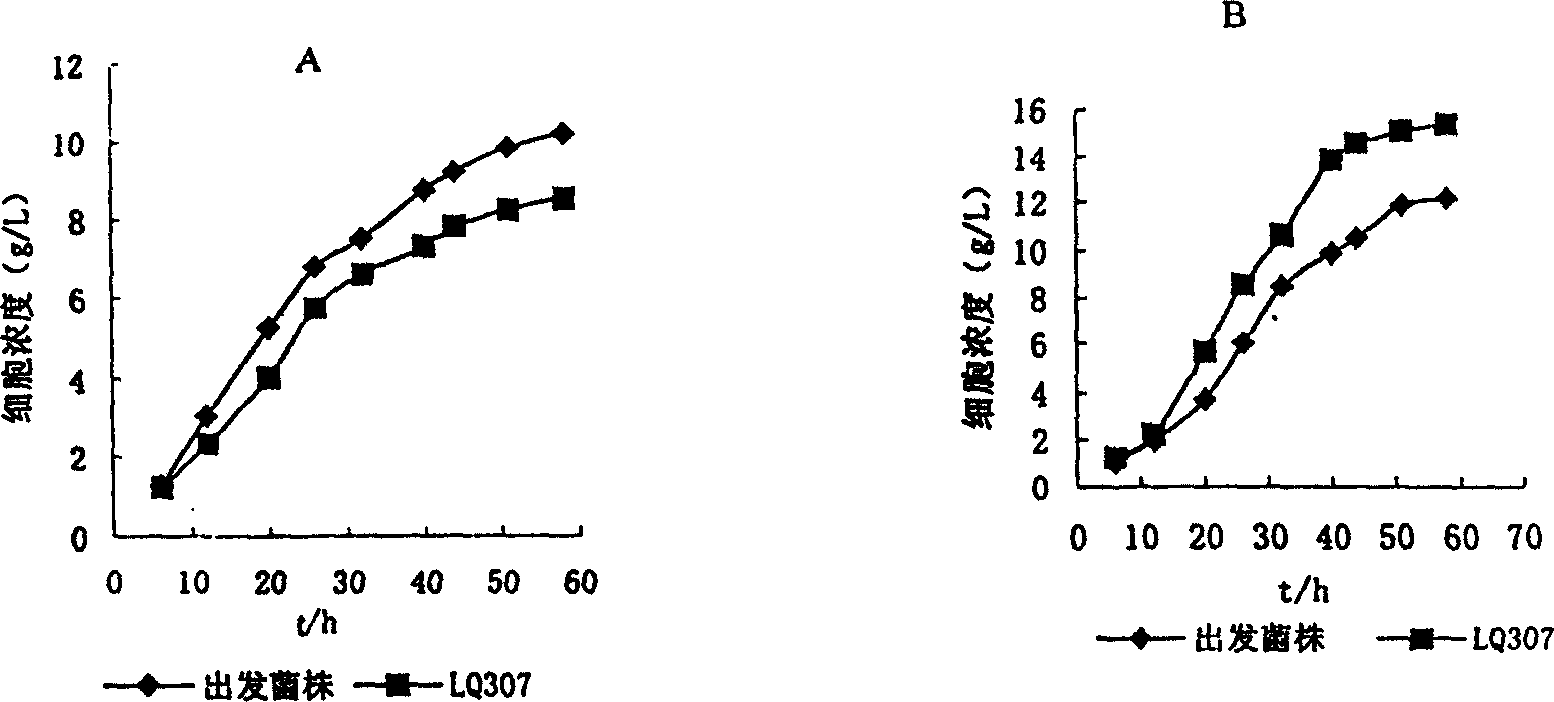

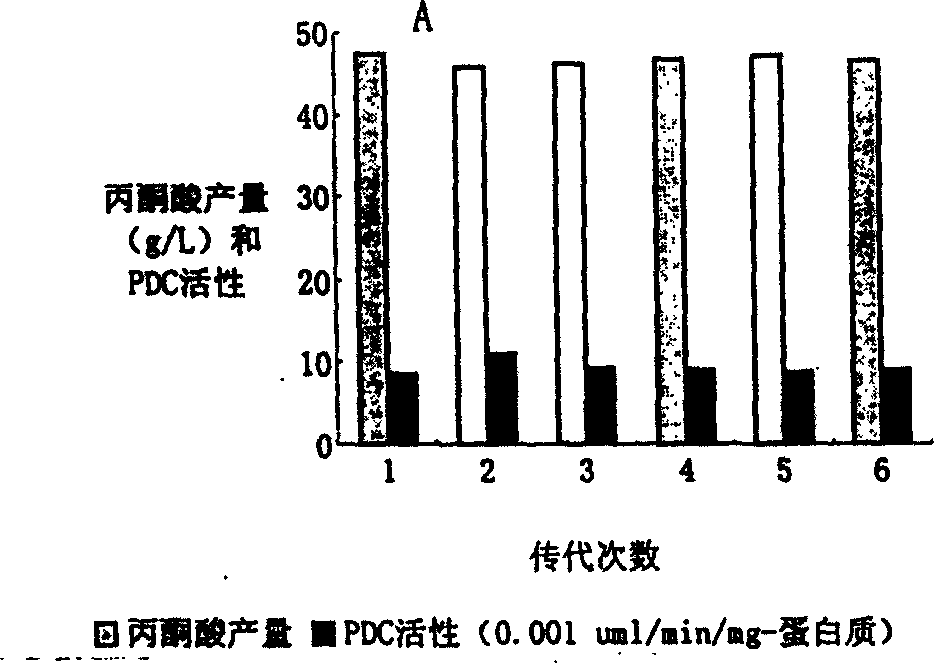

[0056] Embodiment 1: produce pyruvic acid with WSH-LQ307 fermentation method

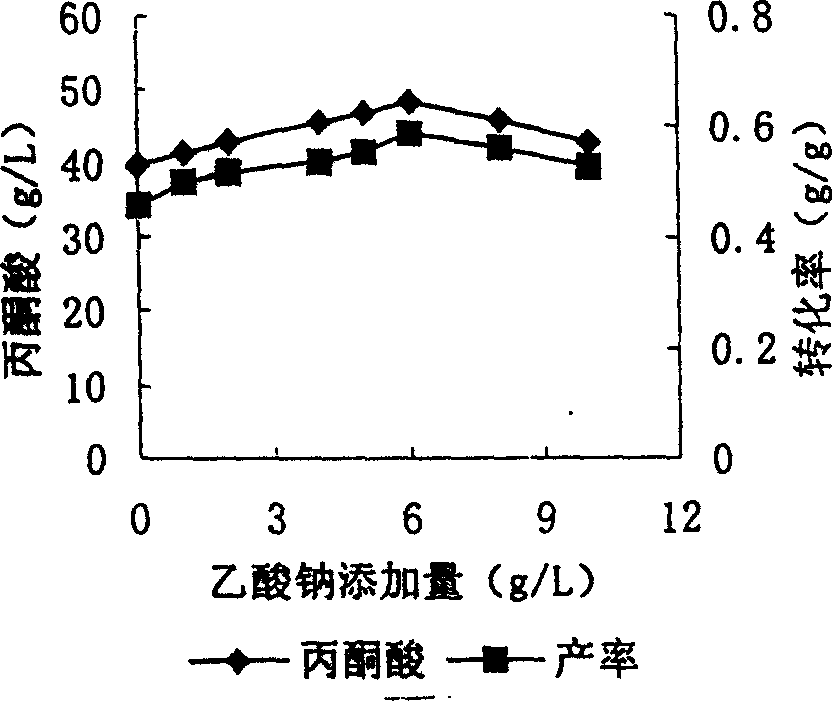

[0057] Connect a ring of LQ-307 strains from a fresh slant into the seed medium (50ml / 500ml Erlenmeyer flask), cultivate at 30°C and 200rpm for 24h, then insert into the fermentation medium with 10% inoculum (v / v) . The composition of the seed medium and the fermentation medium is as described in this specification, and 6 g / L sodium acetate is added to the fermentation medium.

[0058] Shake flask culture: the liquid volume of the fermentation medium in the 500ml Erlenmeyer flask is 50ml, and the rotation speed is 200rpm. The fermentation time was 48h, and the yield of pyruvate was 46.2g / L.

Embodiment 2

[0059] Embodiment 2: Synthesize pyruvate in 5L fermenter with WSH-LQ307

[0060] Slope seed culture and fermentation inoculation conditions are all the same as in Example 1, and the volume of the fermentation medium (adding 6g / L sodium acetate) in the 5L fermenter is 3L. The ventilation rate is 3L / min, the stirring speed is 700rpm in the first 16h, and it is reduced to 500rpm after 16h, the pH is controlled at about 5.0 with 5mol / LKOH or 5mol / L NaOH, the fermentation temperature is 30°C, and the fermentation equipment is produced by Korean Fermentation Tank Company. A fully automatic fermentation tank model KBT-5L. The fermentation time is 64h. The yield of pyruvate was 68.7g / L, and the conversion rate to glucose was 0.651g / g.

Embodiment 3

[0061] Embodiment 3: synthesize pyruvate with WSH-LQ307 in 300L fermenter

[0062] Slope seed cultivation and fermentation inoculation conditions are all the same as in Example 1, and the 30L automatic fermenter (Changzhou Shuguang Chemical Factory) used for seed cultivation is the KF-30L automatic fermenter produced by Korea Fermenter Company. The reactor used for fermentation is a 300L upper mechanical stirring tank (Changzhou Shuguang Chemical Factory), with a liquid capacity of 200L, an aeration rate of 1L / L min, a stirring speed of 250rpm for 0-16h, and 220rpm after 16h, using industrial alkali ( The mass concentration is about 300g / L), the pH is controlled to be 5.0, and the fermentation temperature is 30°C. The fermentation time is 65h. The yield of pyruvate was 63.8g / L, and the conversion rate to glucose was 0.588g / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com