Trimeric cyanamide joint production method using one step method

A kind of melamine, step method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

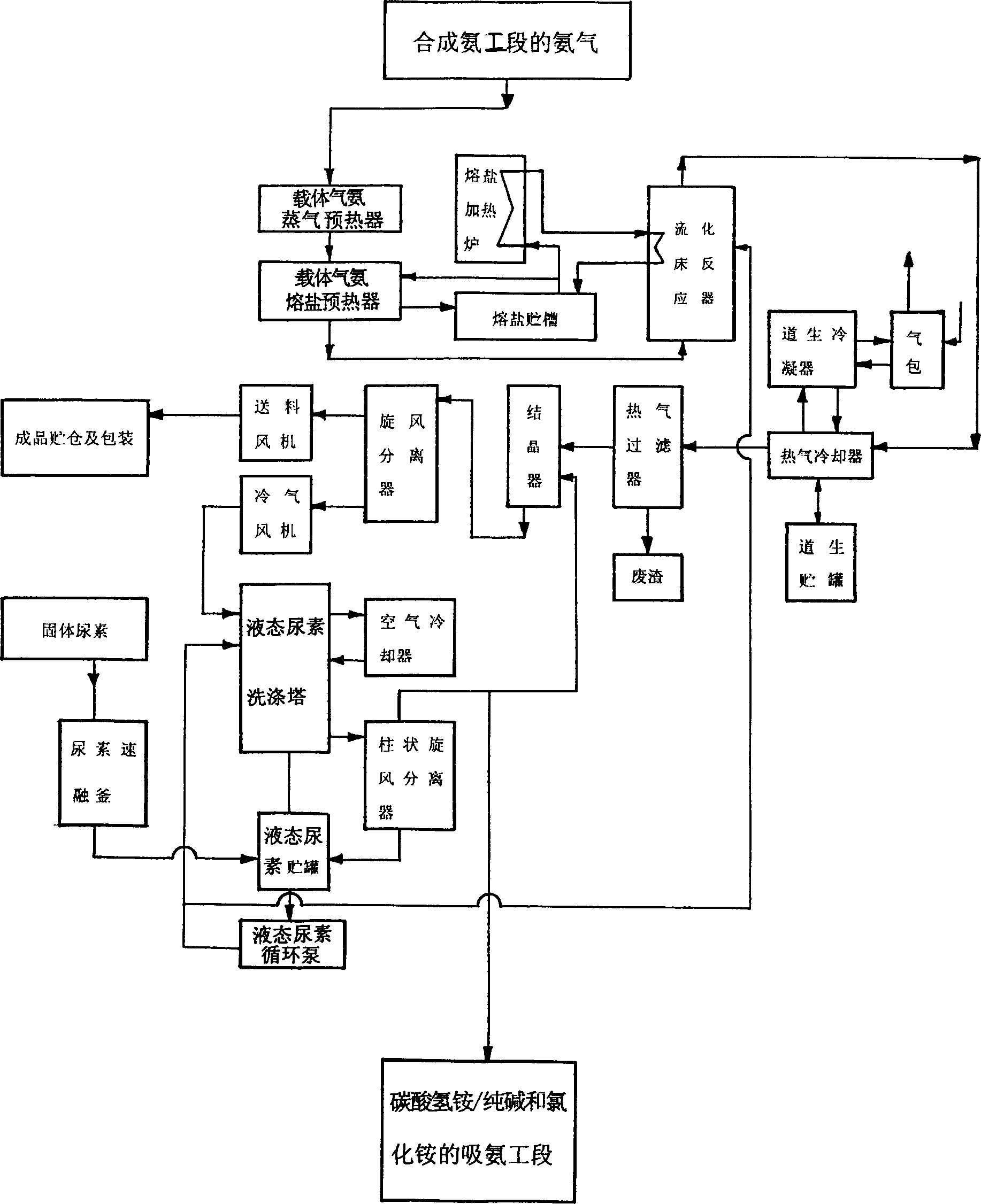

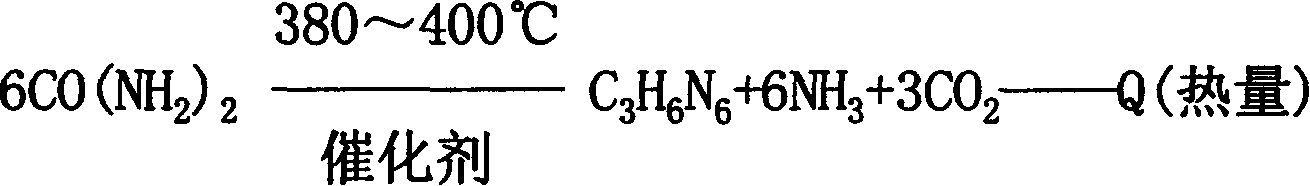

[0018] Embodiment 1, with reference to accompanying drawing, directly select the ammonia gas that comes over from synthetic ammonia workshop section, pressure 0.10~0.15MPa, temperature is 0~5 ℃, every production 1 ton of melamine needs 4400~4800 kilograms of ammonia gas, through carrier gas ammonia vapor The preheater is preheated to 150°C, the pressure is 0.10-0.15MPa, and then heated to 350-400°C by the carrier gas ammonia molten salt preheater; then it enters the fluidized bed reactor as the carrier gas ammonia of the fluidized bed. When the fluidized bed reaction temperature is 380-400°C, the liquid urea branched from the liquid urea circulation pump enters the fluidized bed reactor, and 3.05-3.15 tons of liquid urea is needed to produce 1 ton of melamine. Under the action of catalyst silica gel 60-70 grams of urea can be cast per kilogram of silica gel, and melamine gas is generated through a series of reactions; the melamine-containing gas reacted from the fluidized bed i...

Embodiment 2

[0019] Embodiment 2, with reference to accompanying drawing, directly select the ammonia gas that comes over from synthetic ammonia workshop section, pressure 0.10~0.15MPa, temperature is 0~5 ℃, every production 1 ton of melamine needs 4400~4800 kilograms of ammonia gas, through carrier gas ammonia vapor The preheater is preheated to 150°C, the pressure is 0.10-0.15MPa, and then heated to 350-400°C by the carrier gas ammonia molten salt preheater; then it enters the fluidized bed reactor as the carrier gas ammonia of the fluidized bed. Under the condition that the fluidized bed reaction temperature is 380-400°C, the liquid urea branched from the liquid urea circulation pump enters the fluidized-bed reactor, and 3.05-3.15 tons of liquid urea is needed for every ton of melamine produced. Under the action, 60-70 grams of urea can be cast per kilogram of silica-alumina glue, and melamine gas is generated through a series of reactions; the melamine-containing gas reacted from the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com