High-dispersion nano silicon dioxide preparation method

A nano-silica, high-dispersion technology, used in the preparation of silica, silicon oxide, oxide/hydroxide, etc., can solve the problem of reducing the size of the reaction chamber, affecting the geometric size and shape of the reaction flame, and affecting the uniformity of the product. problems such as continuity and quality to achieve the effect of improving continuity and preventing deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

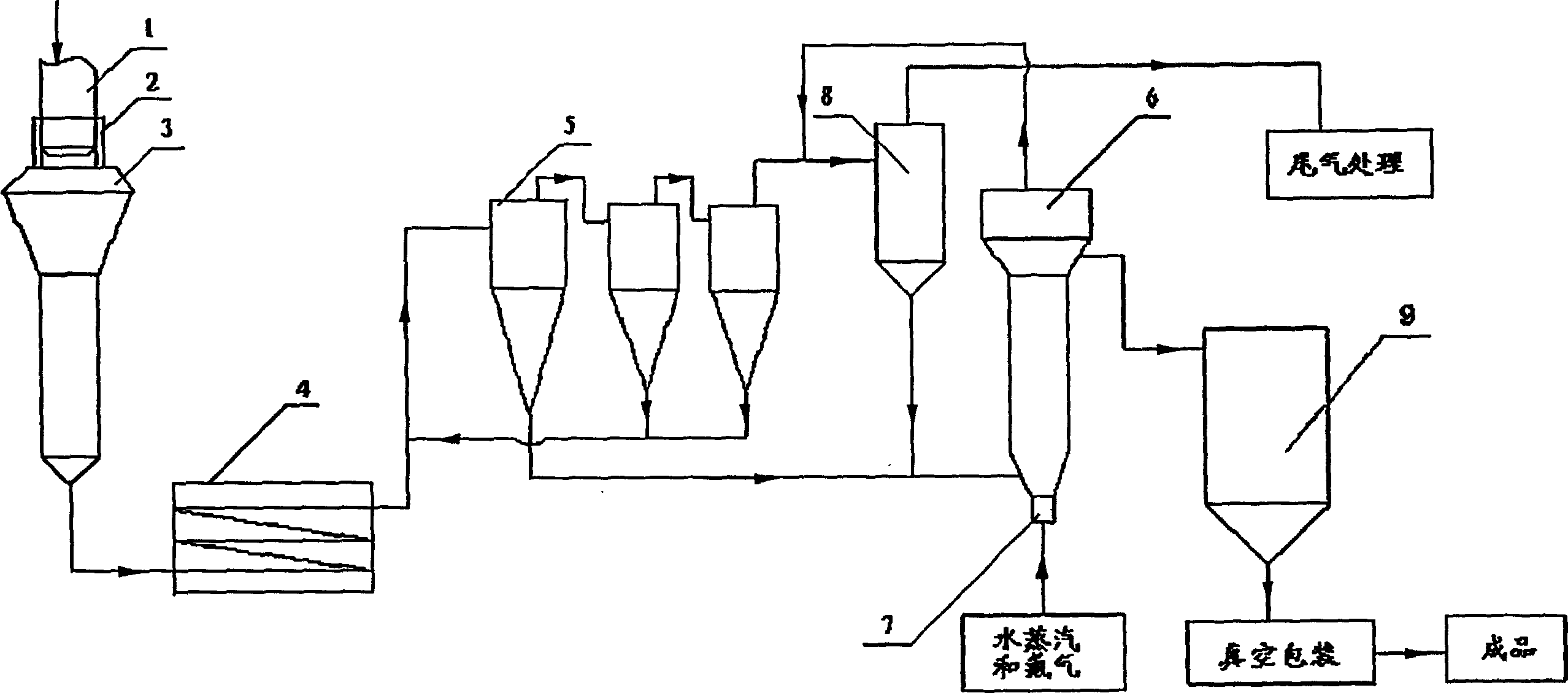

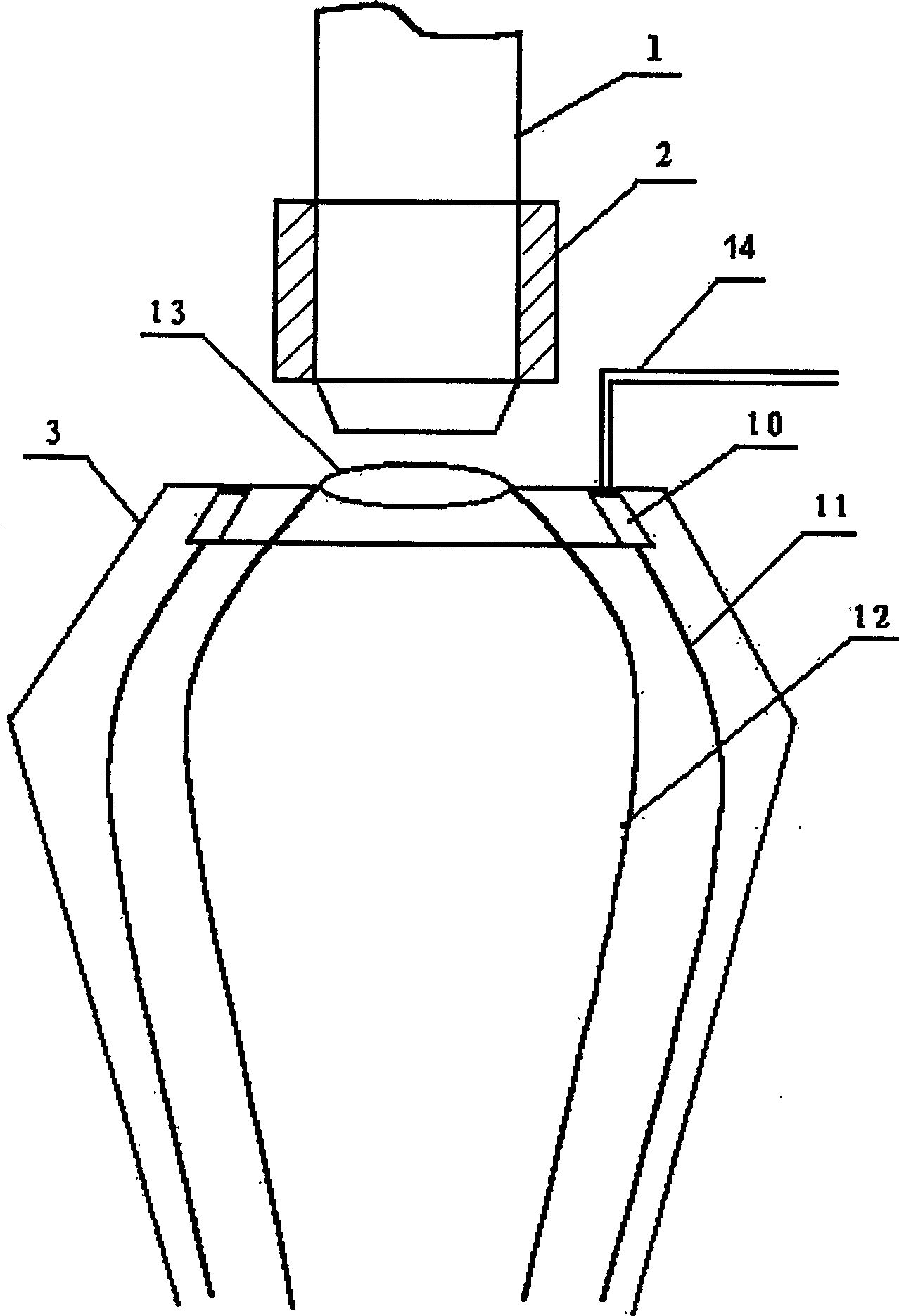

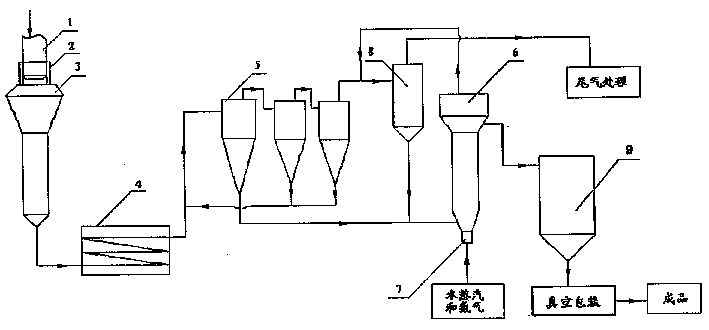

[0026] Methyltrichlorosilane at 7.5m 3 / h, hydrogen at 8m 3 / h, air at 85m 3 The supply of / h is continuously sent to the premixer for premixing (the above volume is the standard volume), and it is preheated to 120°C and then enters the burner nozzle. The specific process is as follows figure 1 , the protective gas is air, the temperature in the deacidification furnace is 550°C, and the temperature of water vapor and nitrogen is 200°C. The quality indicators of the prepared silica are as follows:

[0027]Silica content (%) 99.80

[0028] Primary particle average particle size (nm) 20

[0029] Specific surface area (m 2 / g) 153

[0030] PH value 3.95

[0031] Carbon content (%) 0.01

Embodiment 2

[0033] The methyl trichlorosilane of embodiment 1 is replaced with silicon tetrachloride, and silicon tetrachloride is 7m 3 / h, hydrogen at 8.5m 3 / h, air at 72m 3 The supply of / h is supplied, and other processing parameters are identical with embodiment 1, and the silicon dioxide quality index of making is as follows:

[0034] Silica content (%) 99.85

[0035] Primary particle average particle size (nm) 16

[0036] Specific surface area (m 2 / g) 197

[0037] PH value 4.05

[0038] Carbon content (%) Not determined

Embodiment 3

[0040] The methyltrichlorosilane in Example 1 is replaced with 60% methyltrichlorosilane and 40% silicon tetrachloride, and the supply is 10m 3 / h, hydrogen is 12m 3 / h, the air is 96m 3 / h, other processing parameters are identical with embodiment 1, and the quality index of the silicon dioxide that makes is as follows:

[0041] Silica content (%) 99.82

[0042] Primary particle average particle size (nm) 15

[0043] Specific surface area (m 2 / g) 208

[0044] PH value 4.03

[0045] Carbon content (%) 0.01

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com