Porous film

A porous thin film and thin film technology, applied in the direction of membrane, membrane technology, thin material processing, etc., can solve the problems of mechanical strength reduction, dangerous electrical short circuit, ion permeability reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

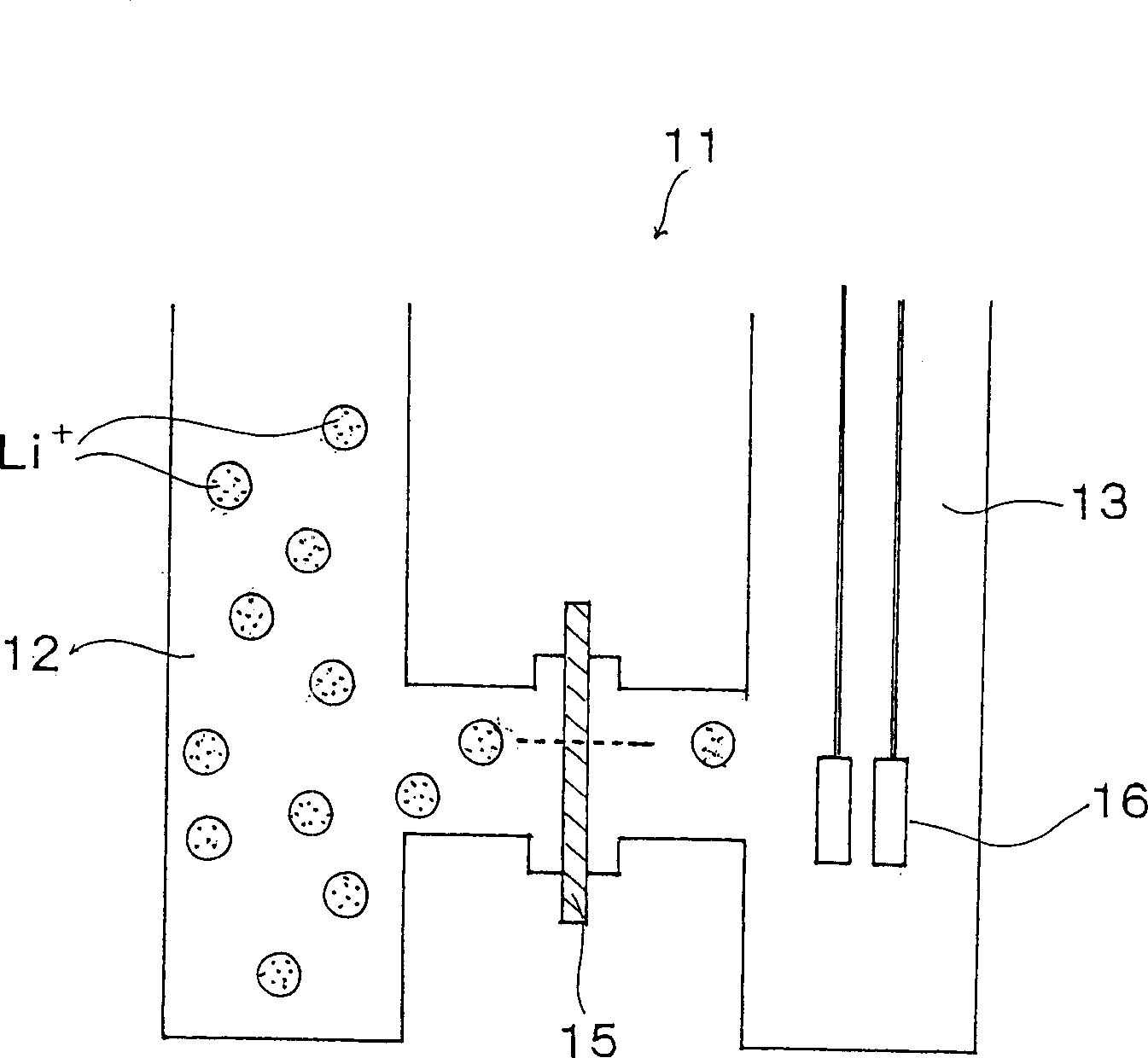

Method used

Image

Examples

Embodiment 1

[0067] Using a stagewise designed twin-screw kneader (produced by Research Laboratory of Plastics Technology Co., Ltd.) so that 30% by volume of calcium carbonate Starpigot 15A (average particle diameter of 0.15 μm, produced by Shiraishi Calcium Co., Ltd.) can Forced kneading with 70% by volume of a mixed polyethylene resin, so that these materials are kneaded, to obtain a resin composition, said polyethylene resin is made of 70% by weight polyethylene film (Highzex Million 340M, weight average molecular chain length is 17000nm, An average molecular weight of 3,000,000, a melting point of 136°C, produced by Mitsui Chemicals) and 30% by weight of polyethylene wax (High Wax 110P, a weight average molecular weight of 100, a melting point of 110°C, produced by Mitsui Chemicals).

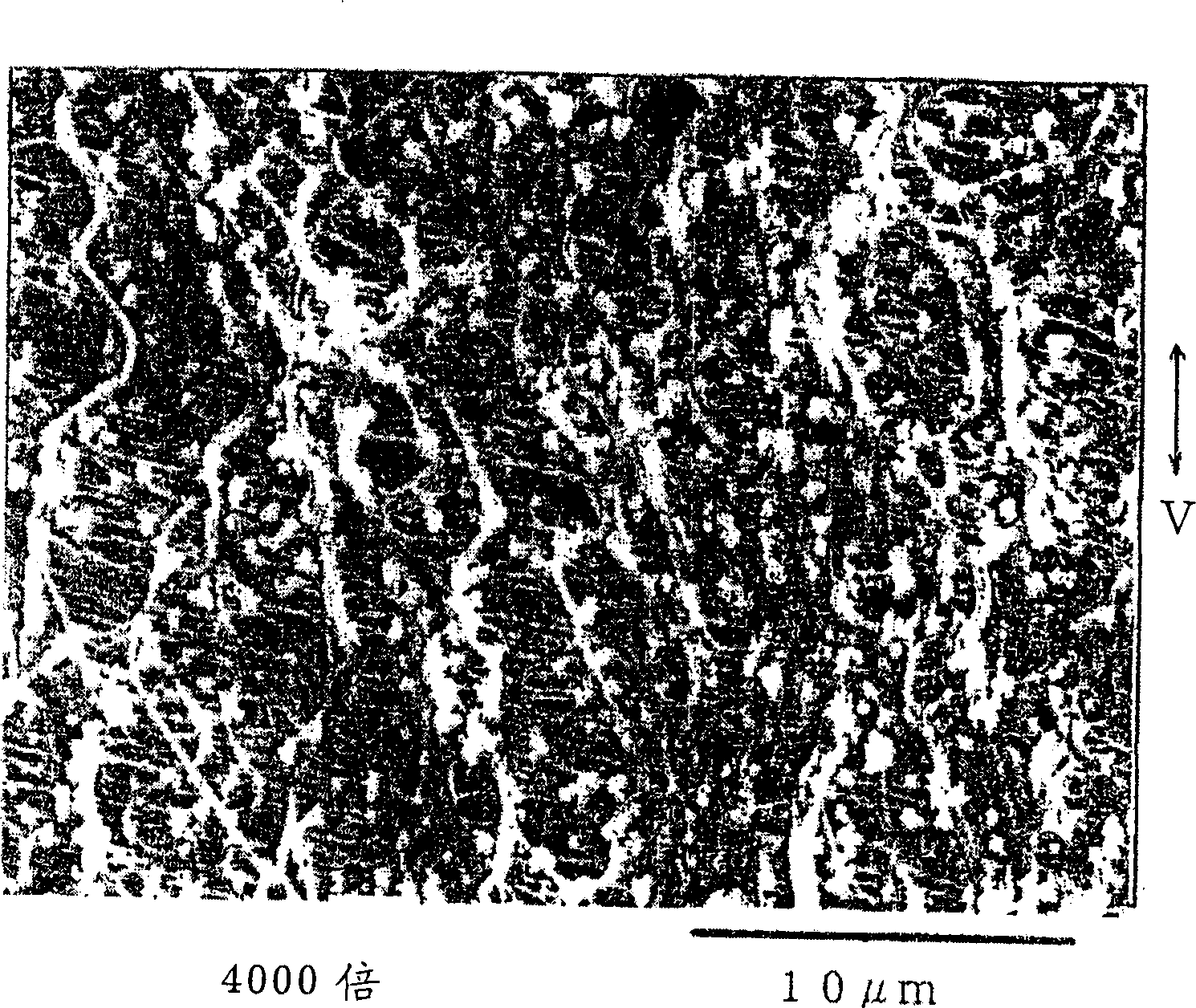

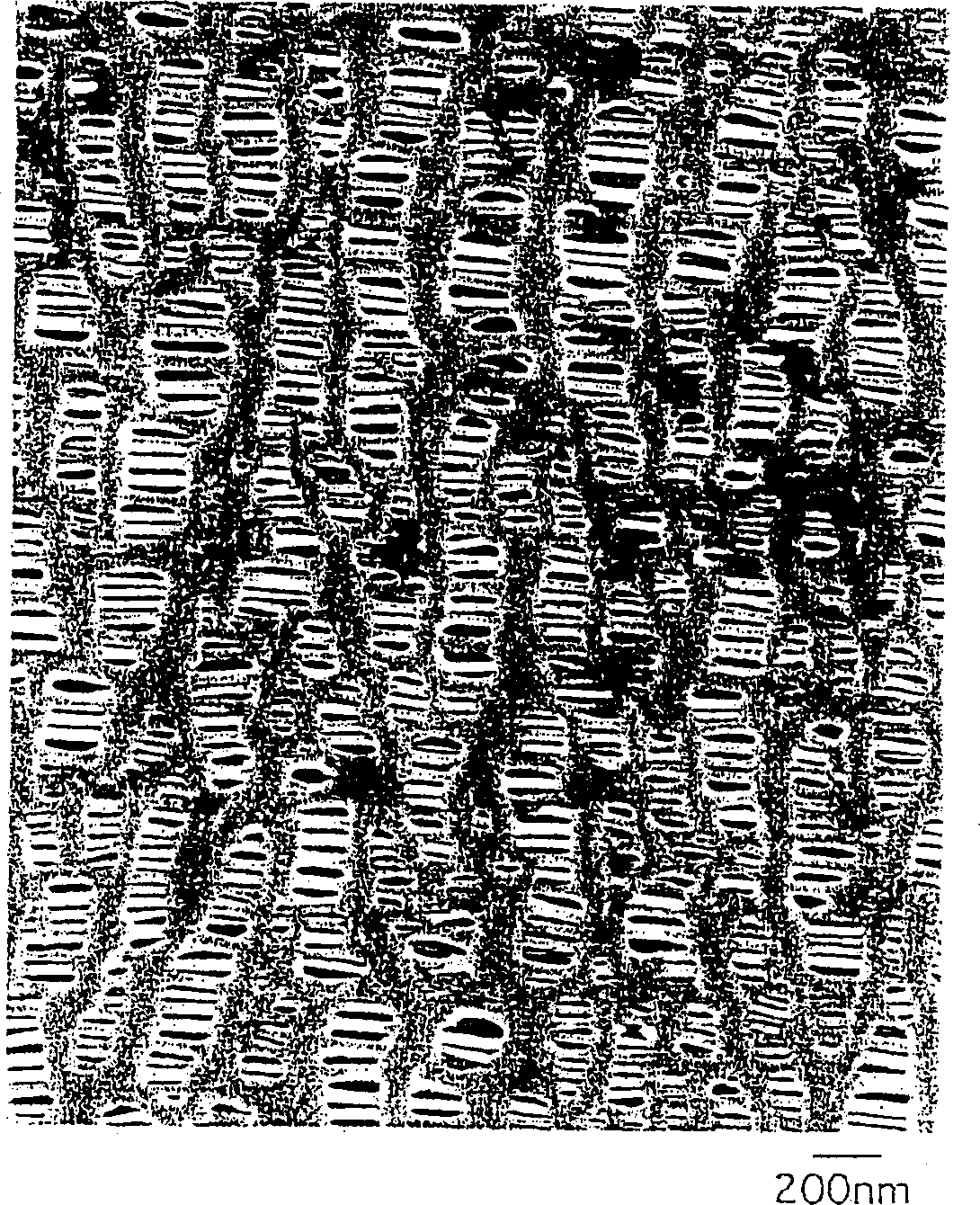

[0068] The content of polyethylene having a molecular chain length of 2850 nm or longer in this resin composition was 27% by weight. This resin composition was calendered (roll temperature: 150° C.) to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com