Needles and manufacturing method thereof

A manufacturing method and needle point technology, applied in the direction of needles, machine needles, and other household appliances, can solve the problems of not being able to improve productivity, poor operability, difficult surface hardness, and fatigue strength, and achieve easy handling and project management. Effect of increased fatigue strength and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

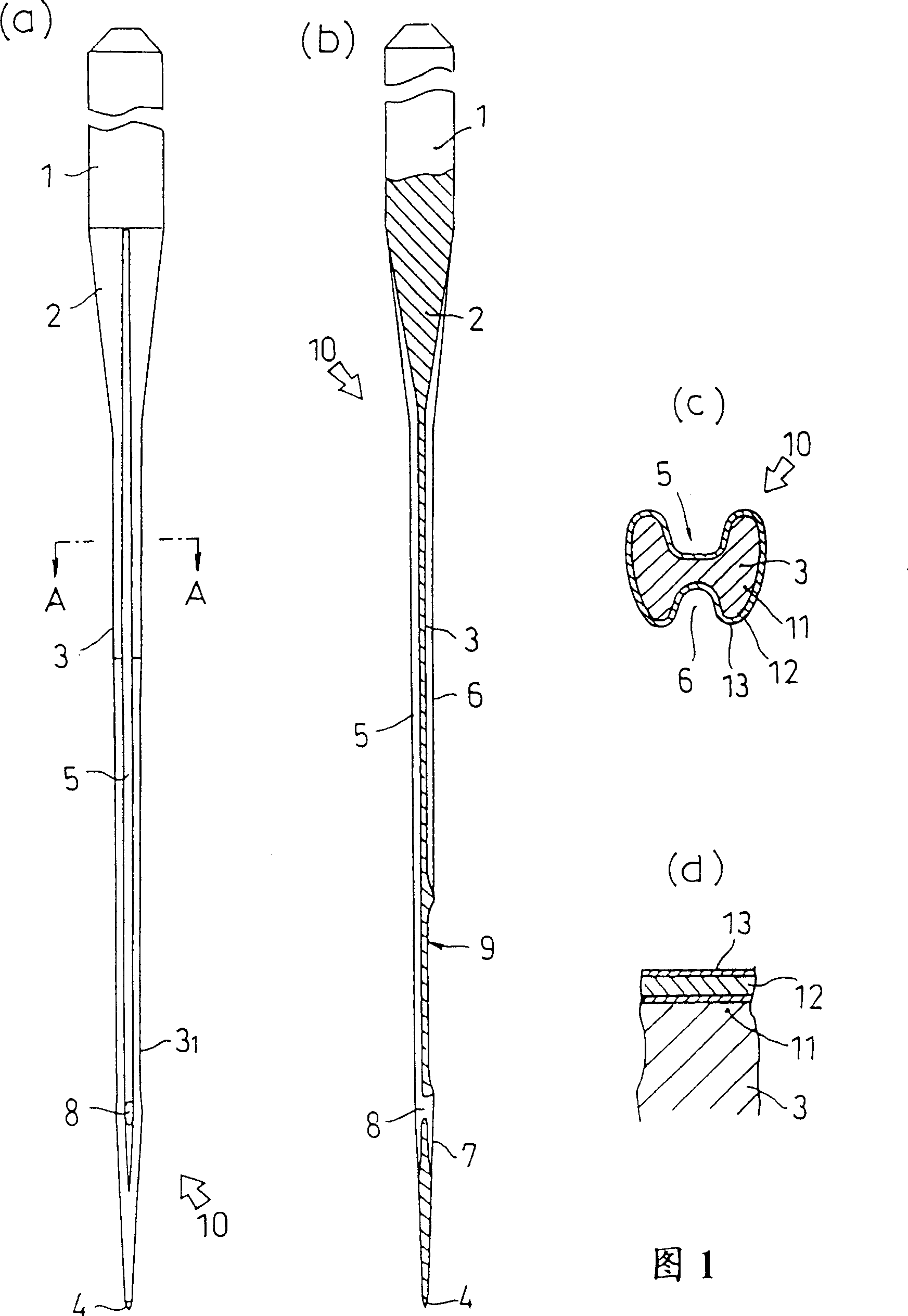

[0017] When the embodiment of the present invention is described by the example of the sewing needle of FIG. The needle main body 3 extending from the other end forms a needle tip 4 at the front end of the needle main body 3, as a continuous concave surface groove 5 extending from the above-mentioned needle handle part 1 to a position close to the above-mentioned needle tip, in the above-mentioned wire groove 5 The opposite side extends from the above-mentioned needle handle part 1 to the continuous concave inner groove 6 and the short groove 7 near the above-mentioned needle point 4, the needle hole part 8 communicating with the above-mentioned wire groove 5 and the short groove 7, and in the needle hole part 8 and the thinner part of the above-mentioned needle main body 3 between the inner groove 6, the recess 9 formed relatively close to the position of the pinhole part 8, the metal needle base material is formed by carbon steel or alloy steel, and After heat treatment of q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com