Polishing composition and its polishing method

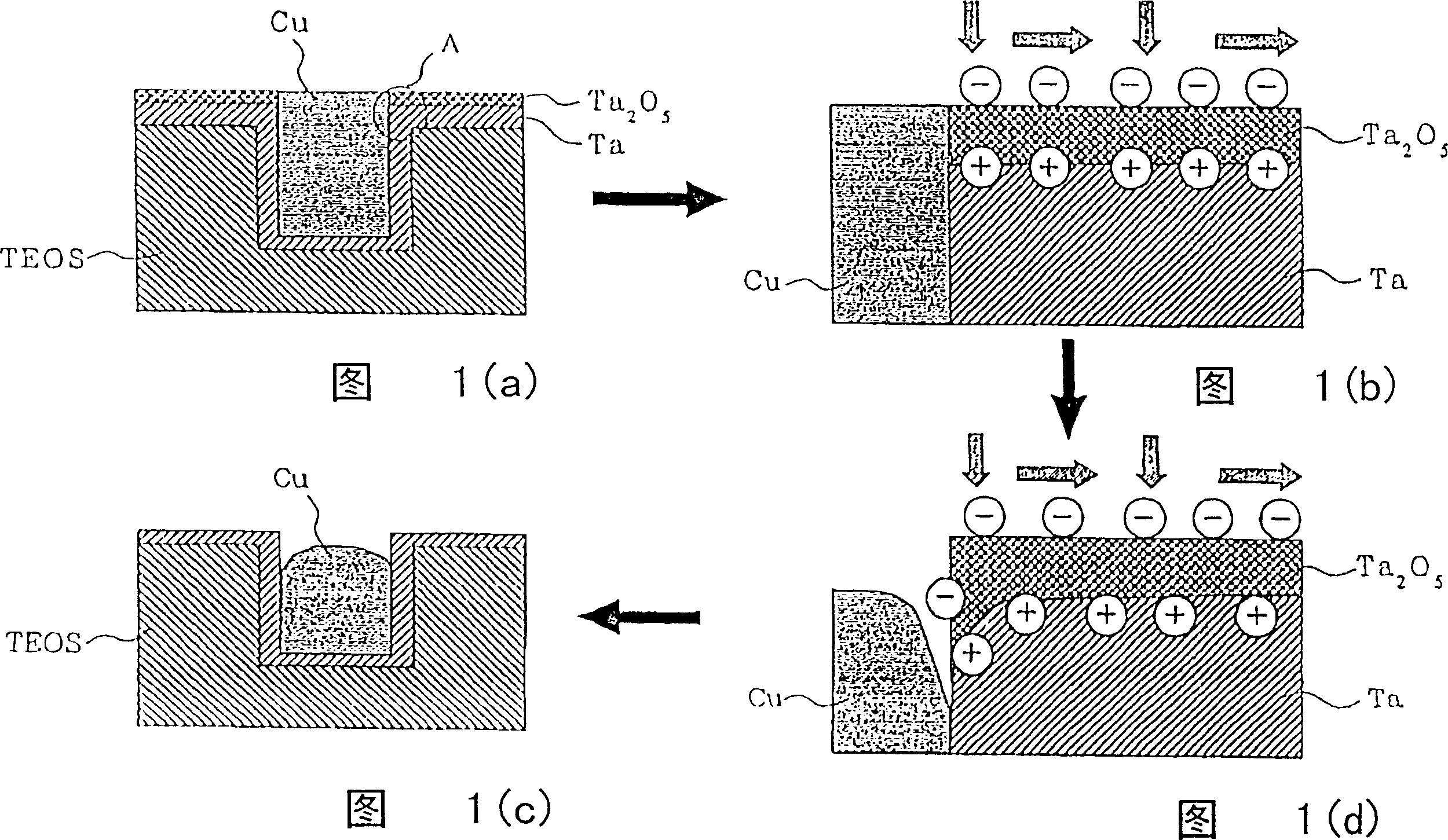

A polishing composition and technology of organic compounds, applied in the polishing field, can solve the problems of long polishing time, low copper layer grinding rate, and inability to obtain sufficient effect of inhibiting chemical corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

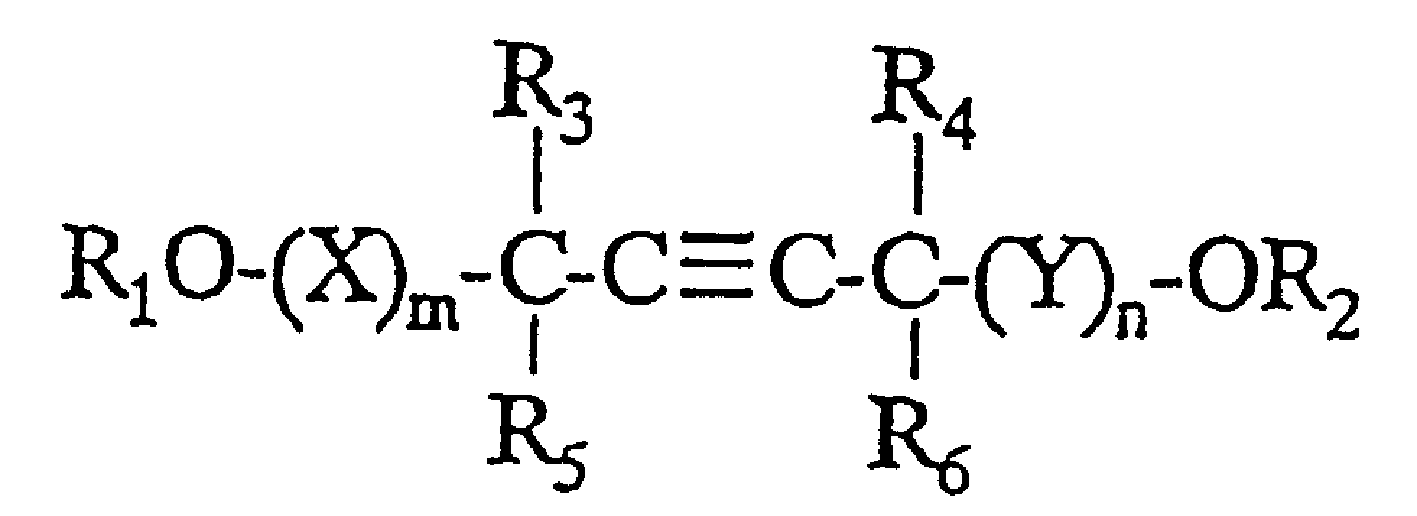

[0083] The preparation method of the polishing composition of the present invention is to dissolve or disperse the above-mentioned components in water, that is, at least one abrasive agent selected from silicon dioxide and aluminum oxide; at least one abrasive agent selected from polyethylene oxide, polyepoxide Organic compounds of propane, polyoxyethylene alkyl ethers, polyoxypropylene alkyl ethers, polyoxyethylene polyoxypropylene alkyl ethers, and polyoxyalkylene addition polymers having C≡C triple bonds represented by formula (1):

[0084]

[0085] where R 1 -R 6 Each is H or C 1-10 Alkyl, each of X and Y is ethyleneoxy or propyleneoxy, each of m and n is a positive integer of 1-20; at least one selected from citric acid, oxalic acid, tartaric acid, glycine, α-alanine and histidine A polishing-accelerating compound of an acid; at least one corrosion inhibitor selected from the group consisting of benzotriazole, benzimidazole, triazole, imidazole, and tolyltriazole; an...

Embodiment 1-57 and comparative example 1-8

[0103] Preparation and Components of Polishing Compositions

[0104] Colloidal silica with an average particle size of 40 nm was used as an abrasive, glycine was used as a compound to accelerate polishing, benzotriazole was used as an anti-corrosion agent, hydrogen peroxide and various types of organic compounds shown in Table 1 were mixed with water , so that they were blended in the ratio shown in Table 1 to prepare various polishing compositions in Examples 1-57 and Comparative Examples 1-8.

[0105] In Examples 1-17, ethylene glycol, polyethylene oxide, polypropylene oxide, polyoxyethylene alkyl ether, polyoxypropylene alkyl ether or polyoxyethylene polyoxypropylene alkyl ether was used as the organic compound , change its molecular weight and dosage, and the contents of other components, namely colloidal silicon dioxide, glycine, benzotriazole and hydrogen peroxide are the same respectively.

[0106] In Examples 18-53, polyethylene oxide (molecular weight 400) or polyoxy...

Embodiment 61-101 and comparative example 9-10

[0132] Preparation and Components of Polishing Compositions

[0133] The colloidal silica with an average particle size of 40nm is used as an abrasive, glycine as a compound for accelerating polishing, benzotriazole as an anti-corrosion agent, hydrogen peroxide and various types shown in Table 2 as an organic compound (organic compound 1 and 2), mixed with water, and mixed according to the ratio shown in Table 2, to prepare the polishing compositions in Examples 61-101 and Comparative Examples 9-10.

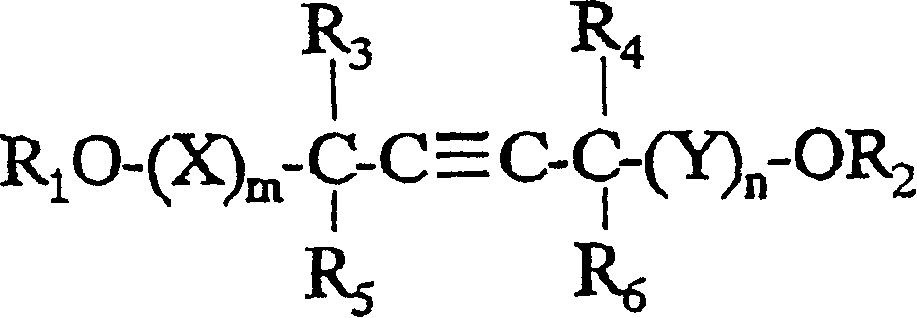

[0134] In embodiment 61-73, used two types of organic compounds, namely organic compound 1 is the diisobutyl dimethyl butynediol polyoxyethylene ether represented by chemical formula (3):

[0135]

[0136] Organic compound 2 is polyoxyethylene polyoxypropylene alkyl ether (molecular weight: 8000), and their usage amounts were changed, and other components, namely colloidal silica, glycine, benzotriazole, and hydrogen peroxide were the same, respectively.

[0137] In Examples ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com