Vacuum microelectronic acceleration transducer

An acceleration sensor and microelectronics technology, applied in the direction of acceleration measurement using inertial force, etc., can solve the problems of small capacitance test method complexity, high low-frequency noise, low sensitivity, etc., to improve long-term stability and temperature stability, signal processing circuit Simple, good temperature stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing the technical scheme of the present invention is further described:

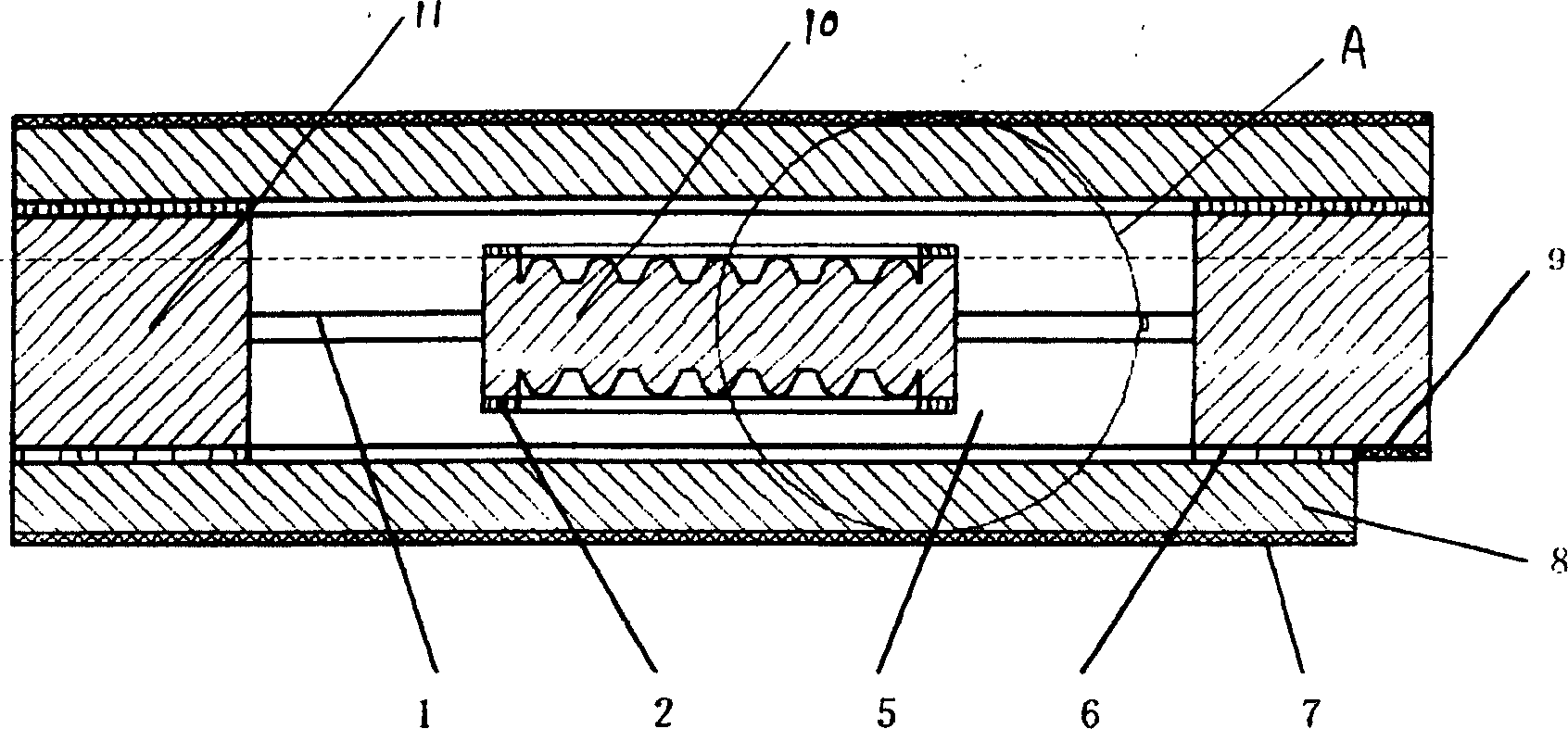

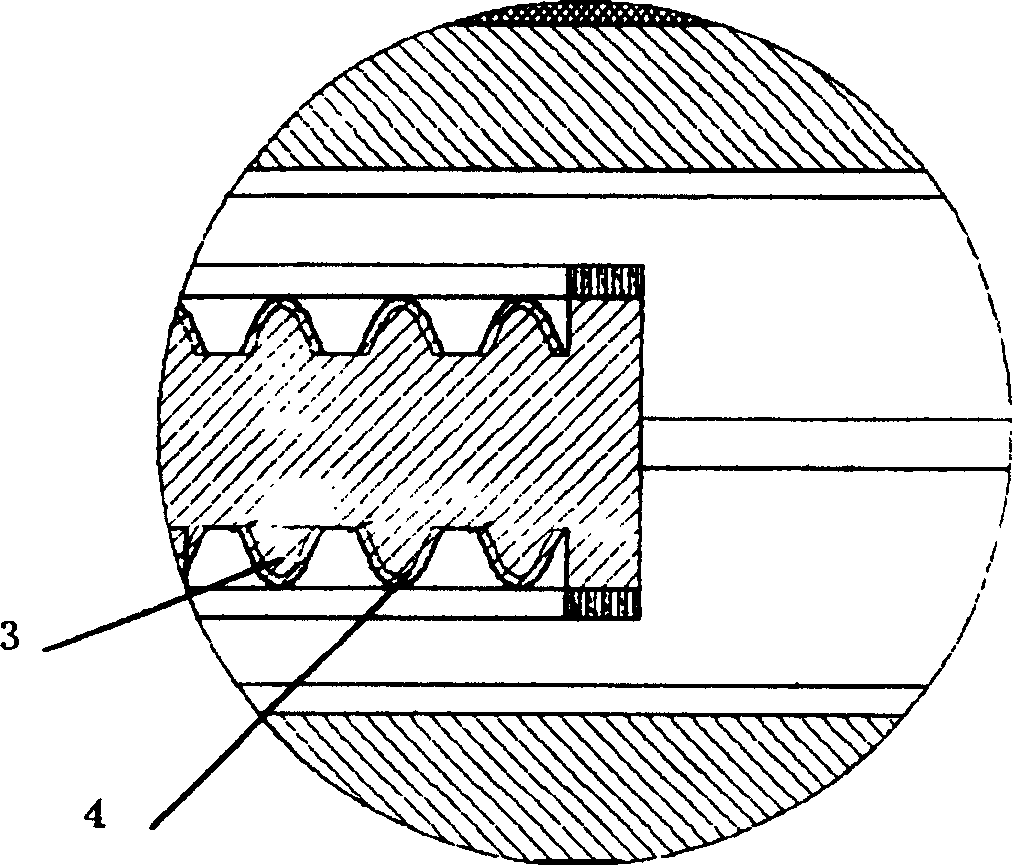

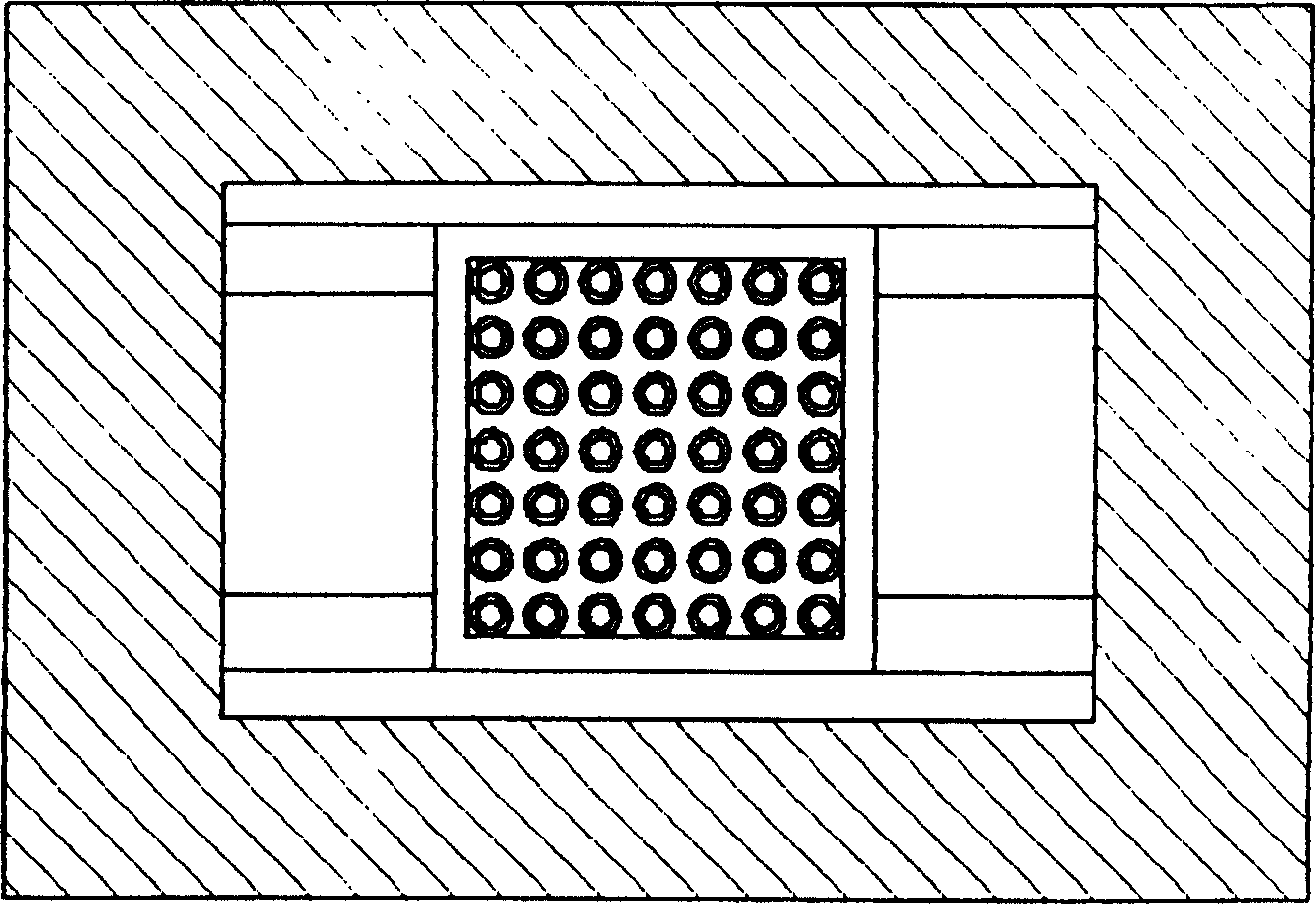

[0021] In the figure, 1 is the cantilever beam of the moving plate, 2 is the overload protection ring, 3 is the silicon micro-field emission cathode cone array on the upper and lower sides of the mass block, 4 is the diamond film, 5 is the vacuum microcavity, and 6 is the insulating layer , 7 is an anode plate output electrode, 8 is an anode plate, 9 is a moving plate output electrode, 10 is a mass block, 11 is a substrate, 12 is an I-V conversion circuit, 13 is a differential circuit, and 14 is a signal filter amplifier circuit.

[0022] see figure 1 , figure 2 , image 3 and Figure 4 , The integrated vacuum microelectronic acceleration sensor mainly includes a moving plate, an insulating layer 6, a vacuum microcavity 5, two upper and lower anode plates 8 and a signal detection circuit. The moving plate is hollow, and is bonded with the upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com