Reactive carbon nano tube and its preparation method

A technology of carbon nanotubes and reactivity, which is applied in the field of reactive carbon nanotubes and its preparation, can solve the problems of limited polymer reinforcement effect, increase the solubility of carbon nanotubes, etc., and achieve the effect of improving mechanical and other properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Mix 1 part by weight of carbon nanotubes with 60 parts by weight of concentrated nitric acid, reflux at reflux temperature for 36 hours, allow it to cool naturally to room temperature, slowly add 100 parts by weight of deionized water to dilute, and add 1mol / L NaOH aqueous solution after cooling Neutralize to make the pH value to 3-4, centrifuge, then wash with deionized water to pH 5-6, wash with acetone once to remove organic matter, and vacuum dry at 100°C for 12 hours to obtain acid oxidation purified carbon nanotubes.

[0031] Add 1 part by weight of the carbon nanotubes obtained by the above method to 30 parts by weight of anhydrous acetone, pass N 2 Protected, add 2 parts by weight of toluene 2,4-diisocyanate dropwise under magnetic stirring, heat up to 50°C and react at a constant temperature for 24 hours after the dropwise addition, filter the product and wash it five times with anhydrous acetone, and dry it in vacuum at 100°C for 12 hours Reactive carbon nano...

Embodiment 2

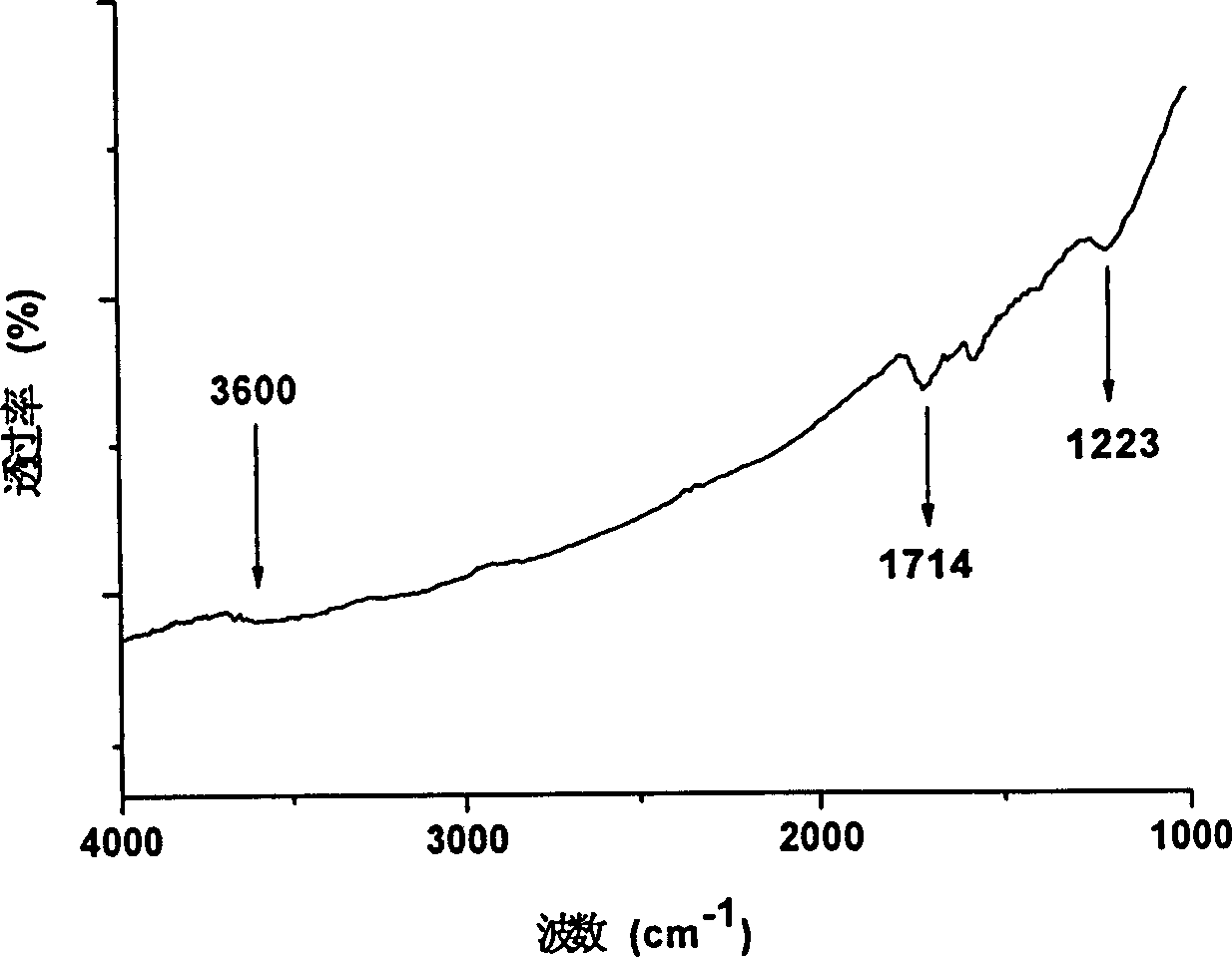

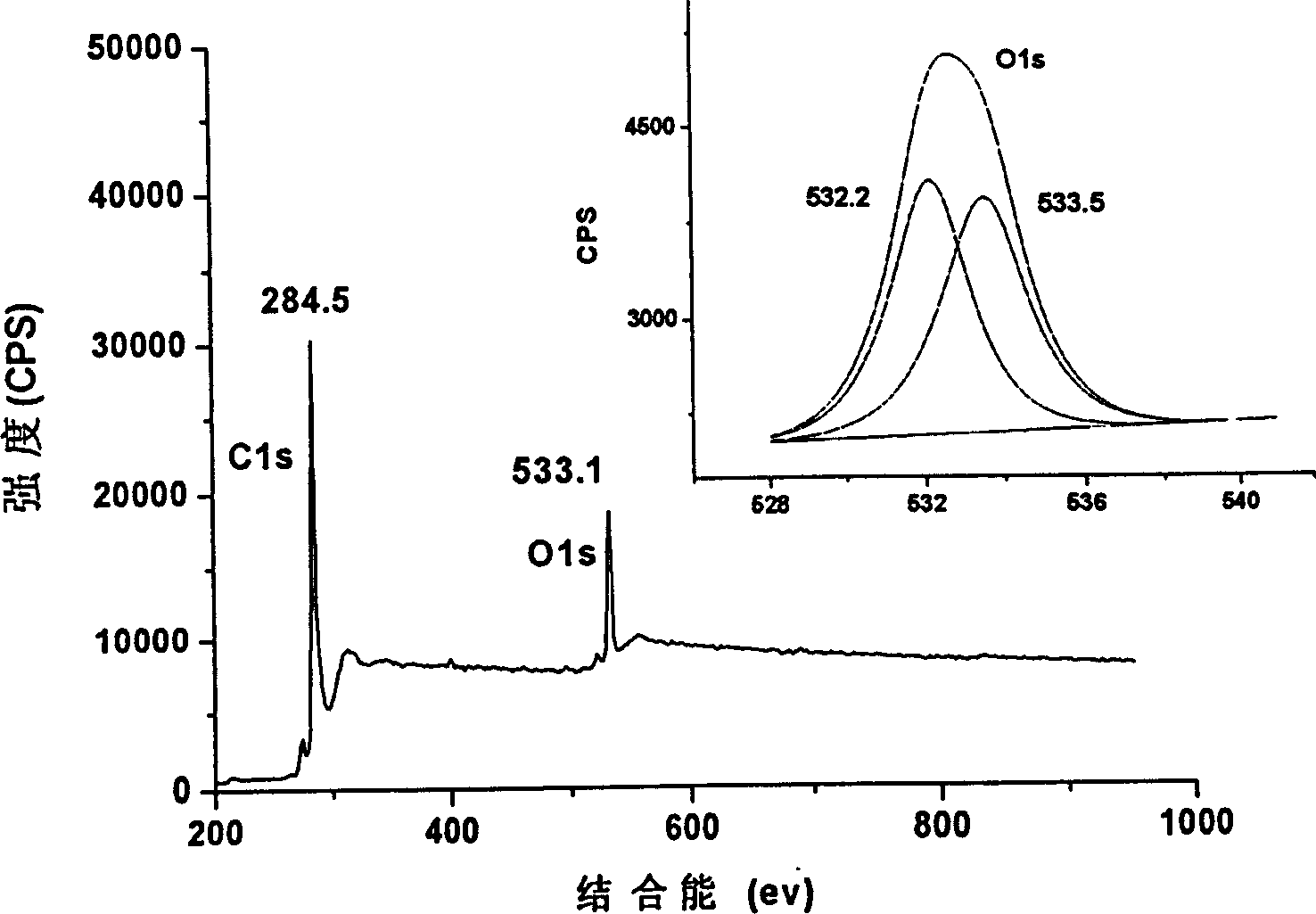

[0033] Mix 1 part by weight of carbon nanotubes with 60 parts by weight of mixed acid (3:1 volume ratio of concentrated sulfuric acid and concentrated nitric acid), reflux at reflux temperature for 36 hours, slowly add 100 parts by weight of deionized water to dilute, and add 1mol / L NaOH aqueous solution to neutralize the pH value to 3-4, filter with suction, wash with deionized water until the pH value is 5-6, wash once with acetone to remove organic matter, and dry in vacuum at 100°C for 12 hours to obtain Acid oxidation of purified carbon nanotubes. Fourier transform infrared spectroscopy (FTIR) and X-ray photoelectron spectroscopy (XPS) confirmed the grafting of carboxyl groups onto carbon nanotubes (see figure 1 and figure 2 ).

[0034] Add 1 weight part of carbon nanotubes obtained by the above-mentioned method into 30 weight parts of anhydrous acetone, pass N 2Protected, add 2 parts by weight of toluene 2,4-diisocyanate dropwise under magnetic stirring, heat up to ...

Embodiment 3

[0036] Mix 1 part by weight of carbon nanotubes with 40 parts by weight of concentrated nitric acid, ultrasonicate at room temperature for 12 hours, slowly add 100 parts by weight of deionized water to dilute, and after cooling, add 1 mol / L NaOH aqueous solution for neutralization to make the pH value to 3-4, centrifuged, washed with deionized water to pH 5-6, washed once with acetone to remove organic matter, and vacuum-dried at 100° C. for 12 hours to obtain carbon nanotubes purified by acid oxidation.

[0037] Add 1 weight part of carbon nanotubes obtained by the above-mentioned method into 30 weight parts of anhydrous toluene, pass N 2 protection, add 0.5 parts by weight of diphenylmethane diisocyanate dropwise under magnetic stirring, raise the temperature to 80°C for 4 hours at a constant temperature and react at a constant temperature for 4 hours, filter the product with suction and wash five times with anhydrous toluene, and vacuum dry at 100°C for 12 hours to obtain R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com