Method of preparation high surface activity rubber powder by waste tyre

A technology of high surface activity, waste tires, applied in the field of preparing high surface activity rubber powder from waste tires, can solve the problems of high energy consumption, high energy consumption and cost, large equipment investment, etc. Small diameter and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

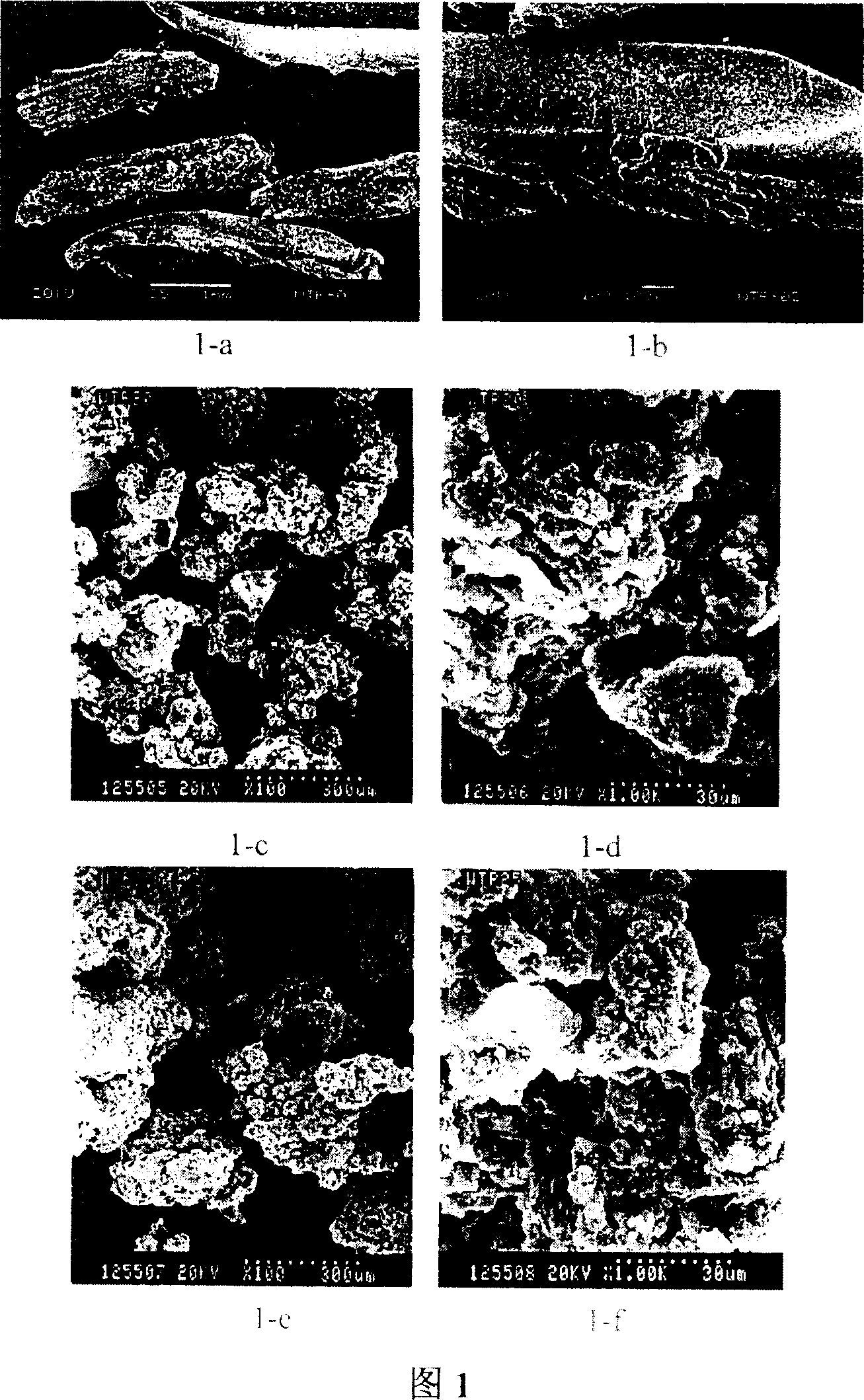

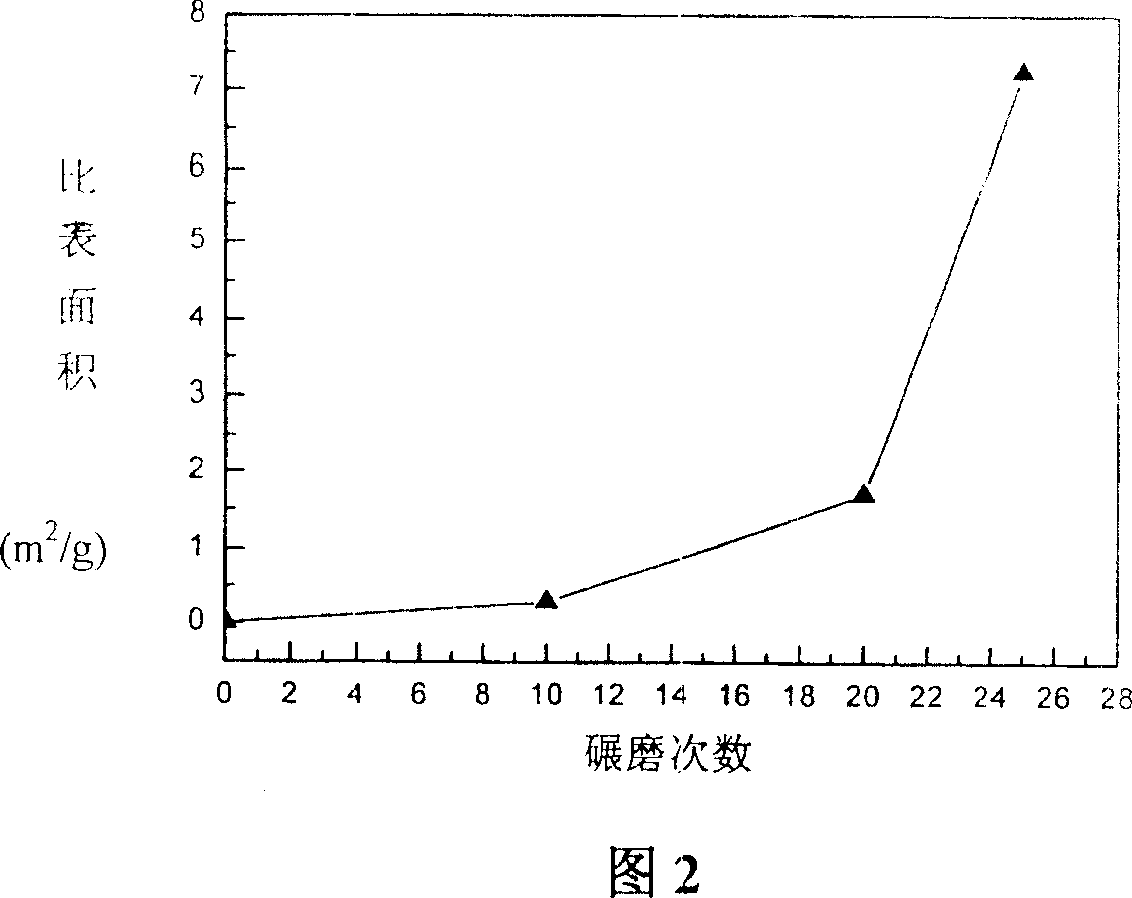

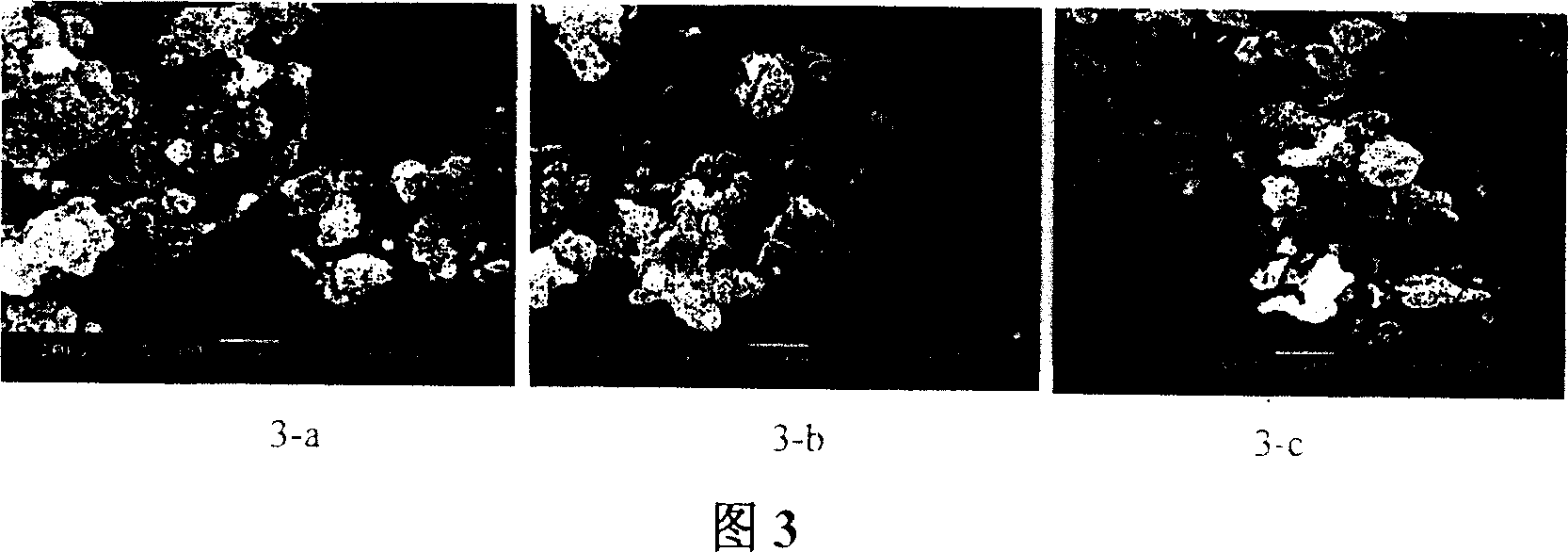

[0037] 1. Introduce circulating water into the cavity on the outer side of the static grinding disc of the disc-shaped mechanochemical reactor, the water temperature is 25±2°C, start the disc-shaped mechanochemical reactor, and control the speed at 30-35 rpm. Through the feeding port, add the clean tread rubber filaments (3-15mm in length, 0.5-1mm in width) obtained from discarded tires to remove the cords, reinforcing steel wires and sediment, and grind and pulverize them. Control the feeding speed to make the materials in the grinding table The residence time in the medium is between 30 and 40 seconds. The grinding process is as follows: (1) Under the static pressure of the grinding surface of 16000-18000kN, after 15 times of grinding, the rubber powder begins to agglomerate; The rubber powder is deagglomerated to obtain fine rubber powder. The specific surface area of the obtained rubber powder is from 0.0073m before milling 2 / g increased to 7.23m 2 / g (measured by BE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com