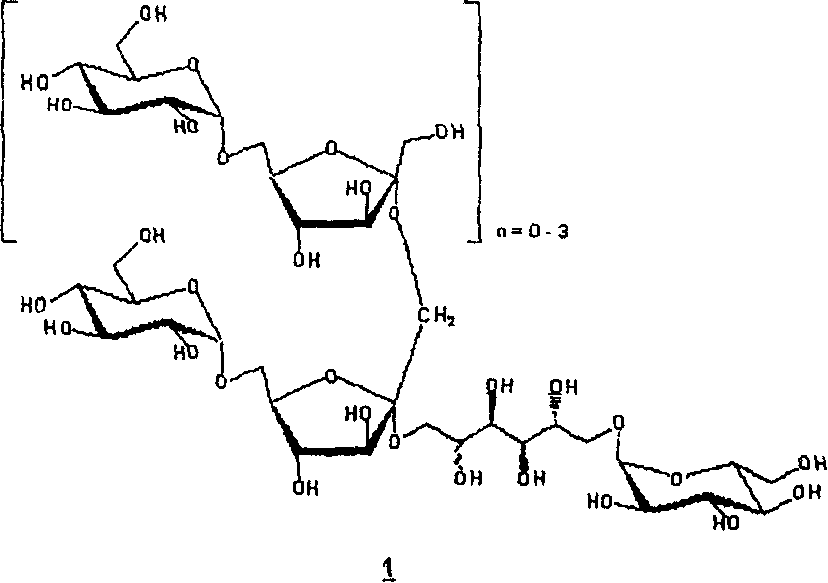

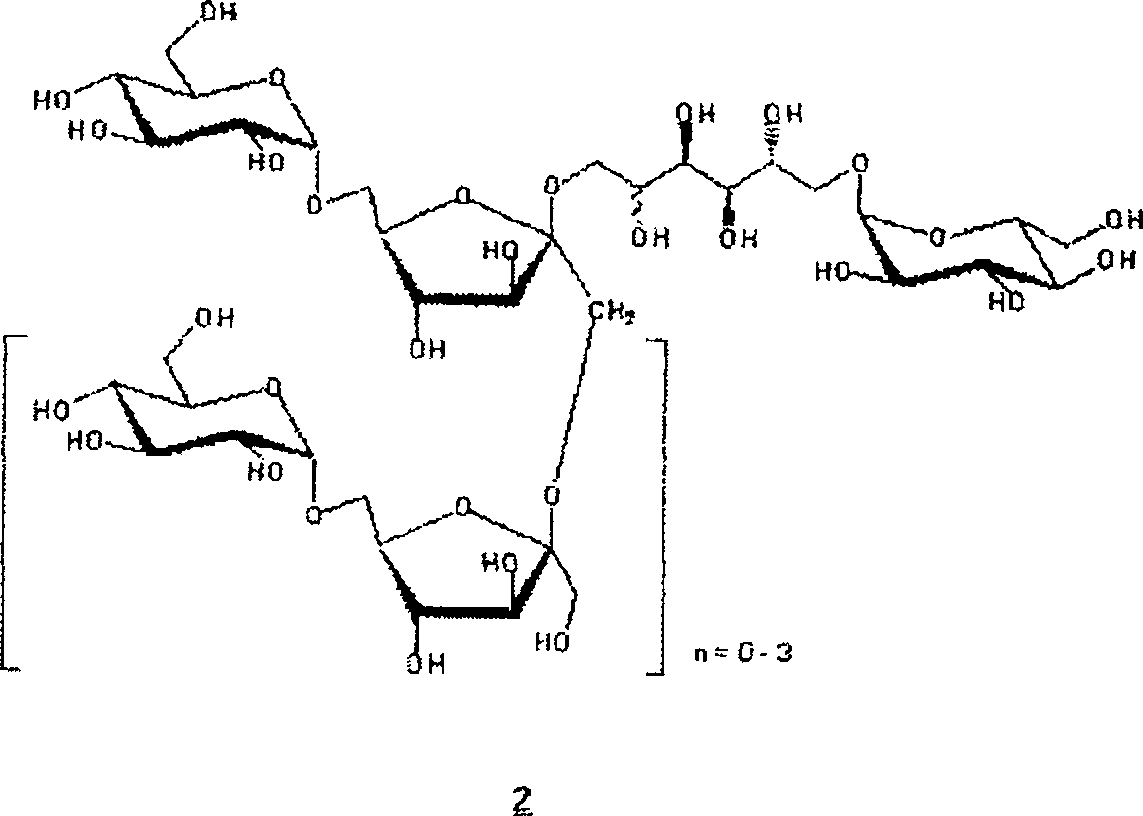

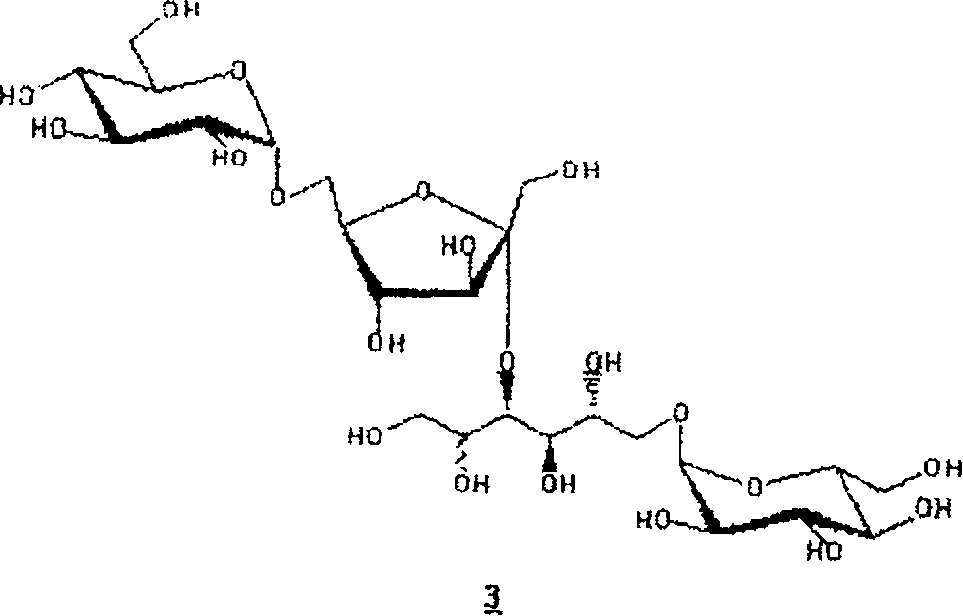

New hydrogenated condensed palatinose products

A palatinose and condensation technology, applied in oligosaccharides, drug combinations, organic chemistry, etc., can solve the problem of unstable resistant starch and achieve the effect of reducing reactivity and increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0128] Preparation of Condensed Palatinose

[0129] 300 g of palatinose crystals and 90 g of water were added into a stainless steel container, stirred at 105° C. to dissolve, and then citric acid (0.02%, based on palatinose) was added. Condensate at 135°C under vacuum conditions, and keep the reaction for 30 minutes. The reaction product was dissolved in deionized water after cooling. The resulting solution was passed through the H + type cation exchange resin and OH - Type anion exchange resin for ion exchange to be purified. The following fractions were obtained by gel permeation chromatography:

[0130] The degree of polymerization ranges from 1 to 2%

[0131] The degree of polymerization ranges from 2 to 48%

[0132]The degree of polymerization ranges from 4 to 28%

[0133] The degree of polymerization ranges from 6 to 12%

[0134] The degree of polymerization ranges from 8 to 5%

[0135] The degree of polymerization ranges from 10 to 5%

[0136] The components ...

Embodiment 2

[0139] a) Hydrogenation of condensed palatinose

[0140] Get 500 milliliters of the reaction solution of 30% concentration obtained in Example 1, which contains 50% condensed palatinan, 2% monosaccharide and 40% isomaltulose, and the solution is adjusted under stirring with 1N NaOH pH to 7.8. The hydrogenation was carried out using nickel (wet weight 200 g) as a catalyst in the presence of hydrogen (150 bar) with stirring at 70°C.

[0141] Samples were taken at 0, 1, 2, 3 and 4 hours, and their isomaltulose content and 1,6-GPS (6-O-α-D-glucopyranosyl (1→6)- D-sorbitol) and 1,1-GPM (1-O-α-D-glucopyranosyl (1→1)-D-mannitol). When the quantitative free isomaltulose is converted into 1,1-GPM and 1,6-GPS, the hydrogenation reaction is ended.

[0142] Hour

[0143] After 4 hours of reaction, the isomaltulose contained in the condensed palatinose solution (see Example 1) was completely hydrogenated to 1,6-GPS and 1,1-GPM. The solution obtained after separating the ca...

Embodiment 3

[0150] Labeling of Hydrocondensed Palatinose

[0151] The hydrogenated condensation palatinose product separated in Example 2 was partially hydrolyzed with HCl according to the following conditions:

[0152] Take 0.9 ml of 1% hydrogenated palatinose, mix with 0.1 ml of 1M HCl, and react at 47° C. for no more than 8 hours. Samples were taken at 0, 1, 2, 4, 6 and 8 hours and analyzed by the HPAEC method.

[0153] Hour

mg / L

0

1

2

4

6

8

1,6-GPS

0

12.8

13.6

14.1

14.2

14.4

1,1-GPM

0

13.3

14.1

14.7

15.3

15.4

0

50.0

54.5

57.0

57.3

57.9

Total

0

76.1

82.2

85.5

86.8

87.7

Isomaltulose / 1,6-GPS,

1, 1-GPM ratio

0

2∶1

2∶1

2∶1

2∶1

2∶1

[0154] Mild hydrolysis condition control makes th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com