Pesticide formulations containing alkoxylated tristyrylphenol hemi-sulfate ester neutralized alkoxylated amine surfactants

A surfactant and alkyl technology, which is applied in the direction of surface active detergent composition, sulfate ester preparation, organic chemistry, etc., can solve the problems of poor performance, lack of compatibility of blending components, stability problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

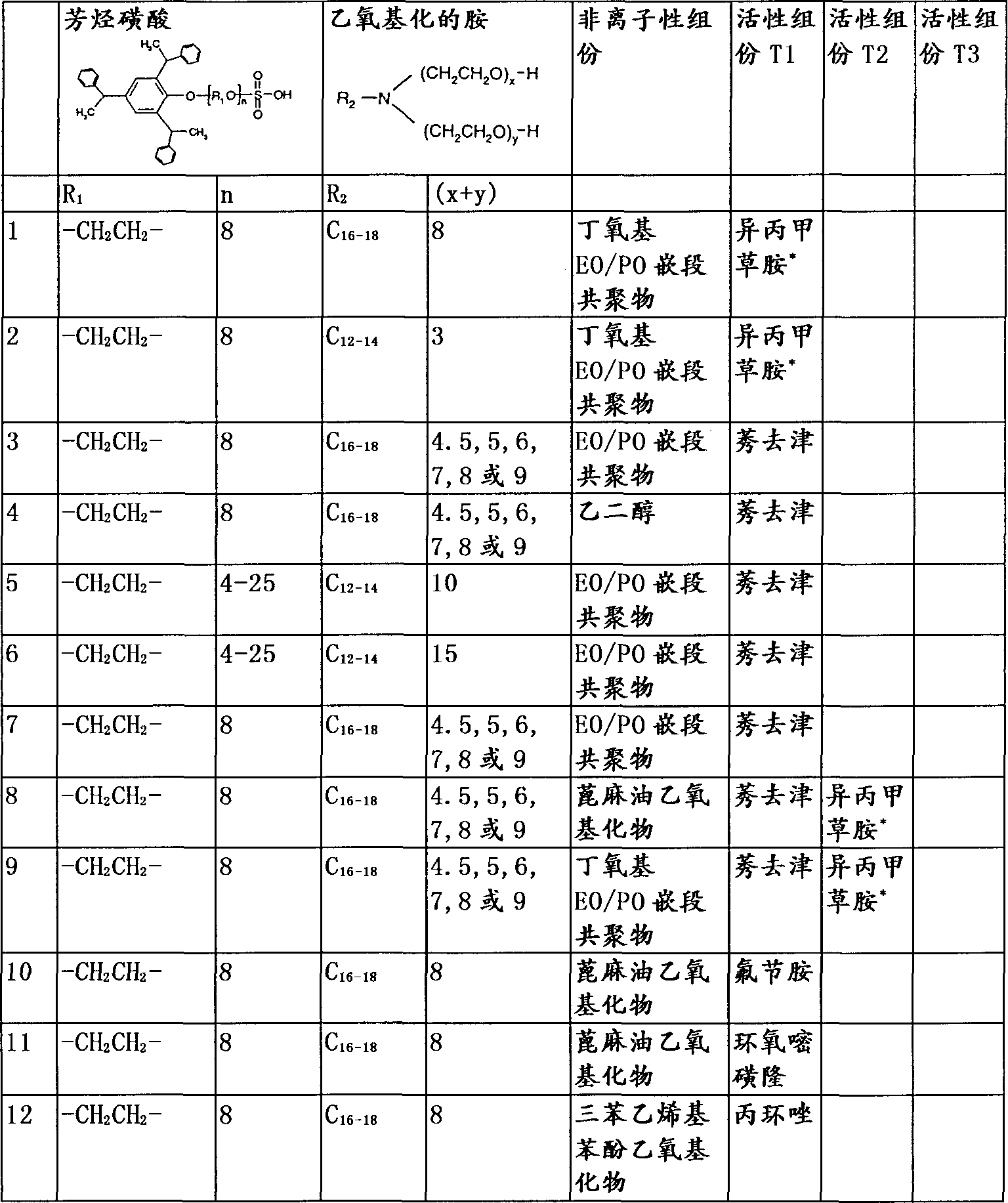

Method used

Image

Examples

Embodiment 1

[0029] An oil-based suspension concentrate containing liquid metolachlor as active ingredient was prepared according to the following formulation: 80.0% by weight metolachlor, 3.0% by weight tallow amine (5EO) neutralized triphenylethylene Phenol Ethoxylation

[0030] (8EO) hemisulfate, 3.0% by weight of tristyrylphenol ethoxylate (20EO), 14.0% by weight of aromatic hydrocarbon solvent.

[0031] The above components were formulated as follows:

[0032] Add tallow amine (5EO) neutralized tristyrylphenol ethoxylate (8EO) hemisulfate and tristyrylphenol ethoxylate (20EO) to a vessel containing the aromatic solvent and mix . Then add industrial metolachlor and mix well.

[0033] It should be understood that the surfactants of the present invention are equally acceptable for water-based and oil-based formulations without limitation.

[0034] Another preferred aspect of the invention comprises the combination of the surfactant system of the invention with a solid active ing...

Embodiment 2

[0036] An aqueous suspension concentrate containing solid atrazine as active ingredient was prepared according to the following formulation: 43.5% by weight of atrazine, 2.0% by weight of tridecyl alcohol ethoxylate (6EO) 1.0% by weight of EO-PO Block Copolymer 2.0% by weight tallow amine (8EO) neutralized tristyrylphenol ethoxylation

[0037] (8EO) hemisulfate, 5.0% by weight of ethylene glycol, and make up to 100% with water.

[0038] The above components are processed and formulated as follows: gradually add atrazine industrial products to triphenyl alcohol containing tridecyl alcohol ethoxylate (6EO), EO-PO block copolymer, and tallow fatty amine (8EO). In a container of vinylphenol ethoxylate (8EO) hemisulfate, ethylene glycol and most of the water. The slurry is mixed until homogeneous and then ground to the appropriate particle size. Add remaining water to meet test specifications.

[0039] Another preferred aspect of the present invention includes the combinati...

Embodiment 3

[0041] An aqueous suspension concentrate containing solid atrazine and liquid metolachlor as two active ingredients was prepared according to the following formulation: 26.1% by weight of s-metolachlor 33.7% by weight of atrazine, 1.31% The tristyryl phenol B neutralized by the tristyryl amine (5EO) of tridecyl alcohol (6EO) of 0.4% by weight of oxazam by weight, 0.4% by weight of tridecyl alcohol (6EO) Oxylation

[0042] (8EO) hemisulfate, 1.5% by weight of tristyrylphenol ethoxylate (35EO), 0.7% by weight of defoamers, 0.03% by weight of thickeners such as xanthan gum 0.03% by weight of biological Inhibitor 1.6% by weight ethylene glycol, made up to 100% with water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com