Process for producing building cement by domestic refuse incinerated slag

A technology of waste incineration and masonry cement, which is applied in the field of cement production, can solve the problems of secondary pollution of slag, etc., and achieve the effect of alleviating economic pressure, enhancing the curing effect, and reducing the expenditure of treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Select slag from Shanghai Jiangqiao Waste Incineration Power Plant, Portland cement clinker produced by Guangzhou Zhujiang Cement Co., Ltd., granulated blast furnace slag and natural dihydrate gypsum produced by Guangdong Shaoguan Iron and Steel Plant, and dry exhaust III from Zhujiang Power Plant grade fly ash, and metakaolin. The above materials are ground separately, and the specific surface area of the slag is controlled to be 350m 2 / kg, the specific surface area of clinker is 370m 2 / kg, the specific surface area of slag is 400m 2 / kg, the specific surface area of gypsum is 390m 2 / kg, the specific surface area of fly ash is 310m 2 / kg, the specific surface area of metakaolin is 390m 2 / kg. Mix according to the ratio in Table 1 (the 0.08mm sieve after mixing is 1% to 3%), the physical properties of the prepared masonry cement are shown in Table 2, and the heavy metal leaching of the product is shown in Table 7.

[0031] Table 1. Formula (%) of 1~...

Embodiment 2

[0037] Slag from Shanghai Jiangqiao Waste Incineration Power Plant, silicate clinker produced by Hengdali Cement Plant in Guangdong Province, granulated blast furnace slag from Liuzhou Iron and Steel Plant in Guangxi Province, natural gypsum, and Class II pulverized coal from Huangpu Power Plant in Guangzhou were selected. Ash and metakaolin are ground together according to the formula in Table 3 to obtain a specific surface area of 320-330m 2 / kg (0.08mm sieve residue is 4% to 6%) of masonry cement. Its physical properties are shown in Table 4, and the leaching toxicity of some samples of heavy metals is shown in Table 7.

[0038] Formulation (%) of Table 3, 6~10# samples

[0039] sample number

[0040] Table 4. Physical properties of 6~10# masonry cement samples

[0041]

[0042] The dissolution of heavy metals in some samples is shown in Table 7. It can be seen from Table 3~Table 4 and Table 7 that when the amount of waste incinerator slag reaches 4...

Embodiment 3

[0044] Slag from Likeng Waste Incineration Power Plant in Guangzhou, silicate clinker produced by the new dry process kiln of Tapai Group in Guangdong Province, granulated blast furnace slag from Shaofeng Iron and Steel Plant in Hunan, natural gypsum in Hunan, and Huangpu Power Plant III in Guangzhou were selected. Grade fly ash, limestone produced in Yingde, Guangdong Province, is ground together according to the formula in Table 5 until the specific surface area is 350-360m 2 / kg (0.08mm sieve residue is controlled at 2% to 3%). The physical properties of the prepared masonry cement are shown in Table 6, and the leaching toxicity of some samples of heavy metals is shown in Table 7.

[0045] Table 5, 11~15# sample formula (%)

[0046] Sample serial number

[0047] Table 6. Physical properties of 11~15# masonry cement samples

[0048]

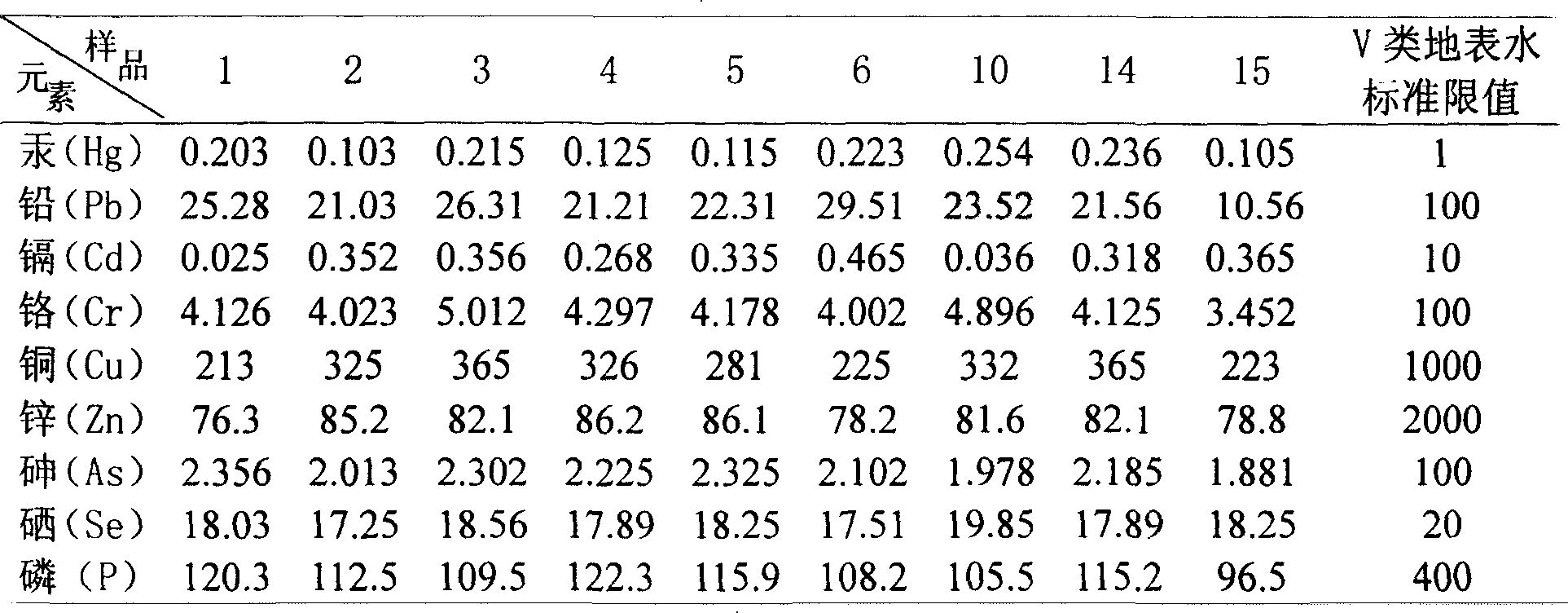

[0049] Table 7, 1 ~ 6 and 10, 14, 15 # samples of heavy metal dissolution (μg / L)

[0050] It can be seen from Table 5~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com