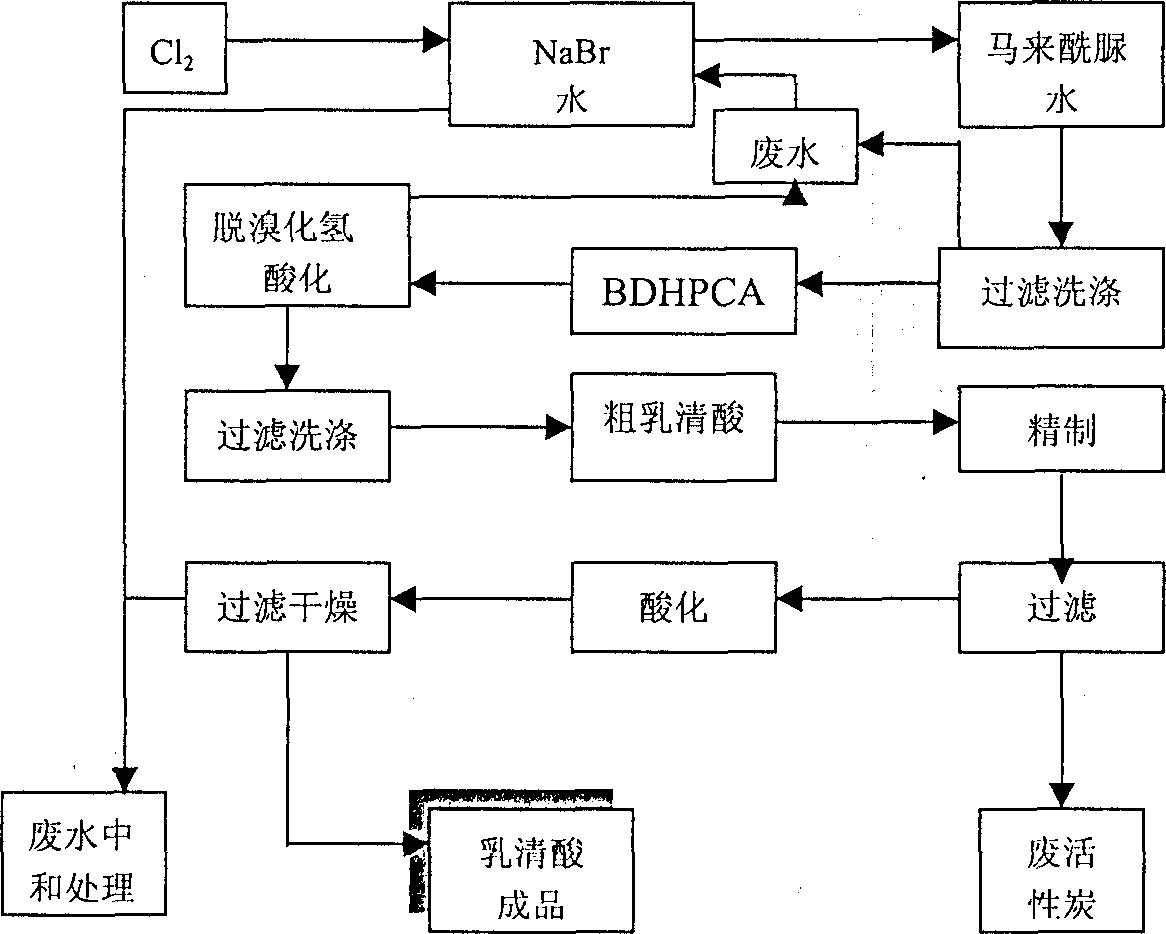

Technological process of producing orotic acid

A process method and orotic acid technology, applied in the direction of organic chemistry, can solve the problems of corrosion and reduce the production cost of orotic acid, so as to reduce the cost, reduce the corrosion and pollution of the environment and equipment, and reduce the pressure of the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of embodiment 1 BDHPCA

[0024] Put 320g of sodium bromide into 1000ml of water, heat, feed chlorine gas, and react with a mixture of 158g of maleuride and 1200ml of water at 0-15°C. The reaction takes about 5-10 hours, and the solid BDHPCA is obtained by filtering and washing. The product does not need to be further dried and purified, and can be directly used in the next reaction. Yield 93%.

Embodiment 2

[0025] Embodiment 2 Preparation of crude product orotic acid

[0026] Put 5.0mol sodium hydroxide or its 30% aqueous solution into 1700ml water, put the intermediate product obtained in Example 1 in 10-30min, heat up to 50-110°C and react for 2-5h, after cooling, add hydrochloric acid to acidify, filter and wash , drying to obtain 110g of product. Yield: 70%.

Embodiment 3

[0027] The refining of embodiment 3 products

[0028] Heat 2000ml of water to 60-100°C, put the crude product into stirring, add 100ml of concentrated ammonia water, it can be completely dissolved, add 10g of activated carbon, boil for 10-30min, acidify with hydrochloric acid, cool to below 5°C and store for 5h, filter, wash and dry Obtain product 100g.

[0029] Product appearance: white crystal or powder, content: >99.5% (HPLC), pH: 2.5 (0.5g / 50ml water), heavy metal content: <20ppm, product ignition residue: 0.07%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com