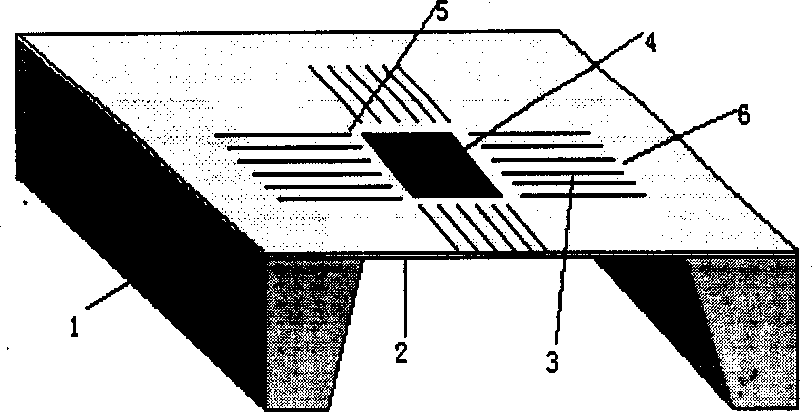

Structure self-aligning method for making infrared absorption layer of infrared snesor for micromechanical heat stack

A technology of infrared detector and infrared absorbing layer, which is applied in the field of micromechanics, can solve the problems of inaccurate positioning and high production cost, and achieve the effects of reducing production cost, improving performance and cost, and positioning accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

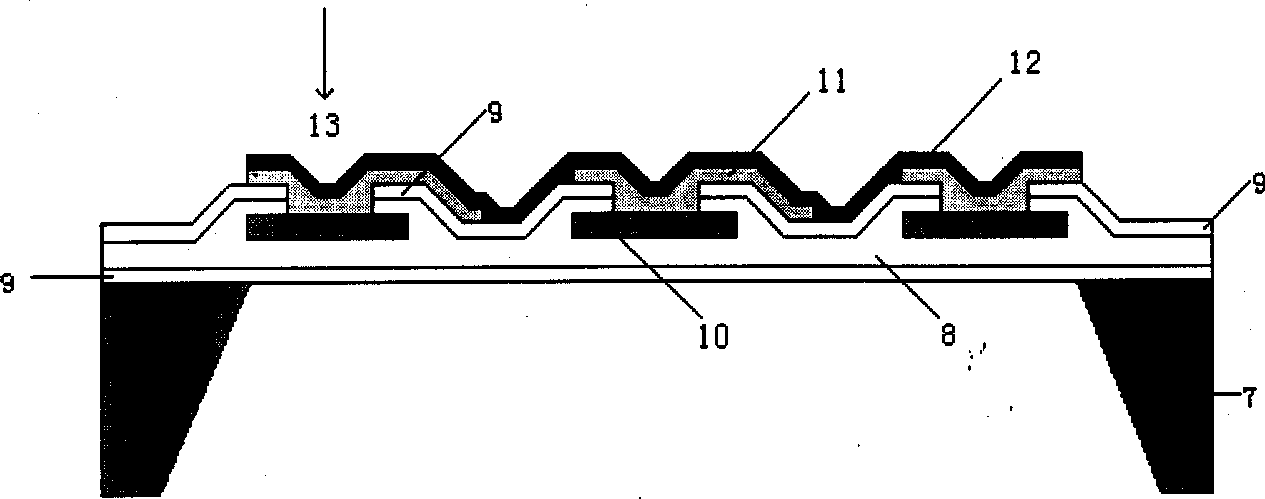

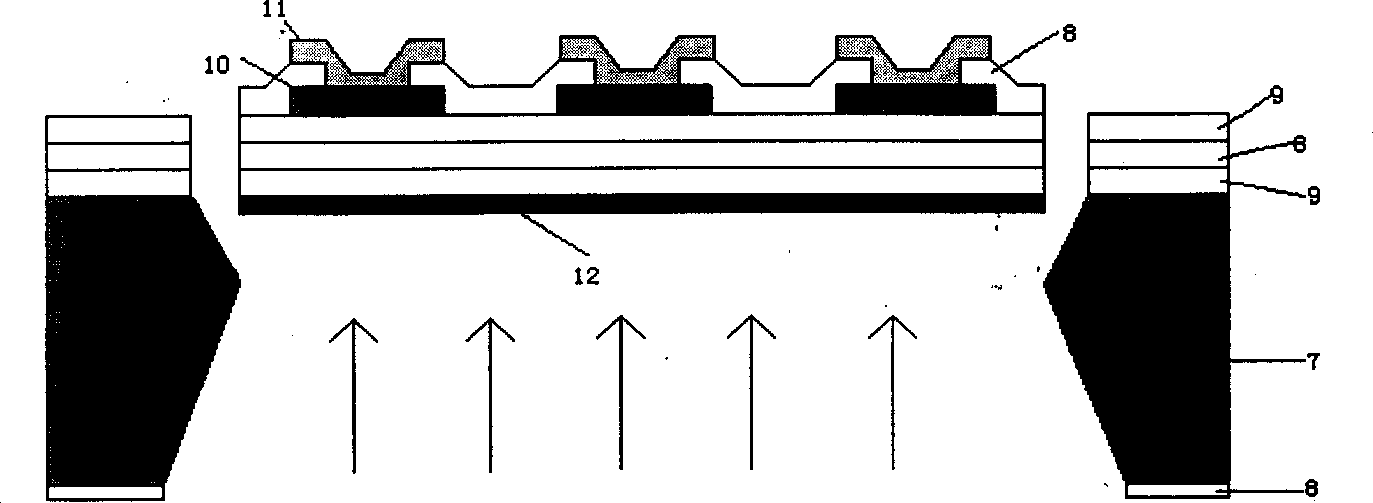

[0023] On the (100) monocrystalline silicon wafer 7, a layer of silicon nitride layer 9 is deposited by low-pressure chemical vapor phase (LPCVD), wherein the LPCVD deposition temperature is 800 ° C, and the thickness of the silicon nitride layer is 0.15 microns; LPCVD deposits polysilicon with a deposition temperature of 640°C and a thickness of 0.6 microns. All of it is thermally oxidized to form silicon oxide 8, and then a layer of silicon nitride is deposited by LPCVD with a thickness of 0.1 microns to form a "silicon nitride-silicon oxide-silicon nitride " sandwich layer.

[0024] Then use LPCVD to deposit a layer of polysilicon with a thickness of 0.6 microns, and carry out boron doping to make it have a certain surface resistance; then thermally oxidize its surface, photolithography the shape of a thermocouple silicon strip, use silicon oxide as a mask, and use The thermocouple silicon strip 10 is formed by dry etching, the strip width is ten to tens of microns, and the...

Embodiment 2

[0029] Thermally oxidize on a (100) single crystal silicon wafer to obtain a layer of silicon oxide with a thickness of 0.5 microns, and then deposit a layer of silicon nitride by LPCVD at a deposition temperature of 800°C with a thickness of 0.15 microns to obtain a layer of "oxidized Silicon-silicon nitride"composite dielectric film. Then use LPCVD to deposit a layer of polysilicon with a thickness of 0.6 microns. After boron doping, the polysilicon strip is photolithographically deposited, and metal aluminum is deposited on the surface to form a thermocouple pair with the polysilicon. When the structure is finally corroded, KOH is used for corrosion to obtain a thermal stack structure. All the other processes are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com