Improved heat and mass transfer apparatus and method for solid-vapor sorption systems

A sorbent and desorption technology, used in lighting and heating equipment, chemical instruments and methods, sorption machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

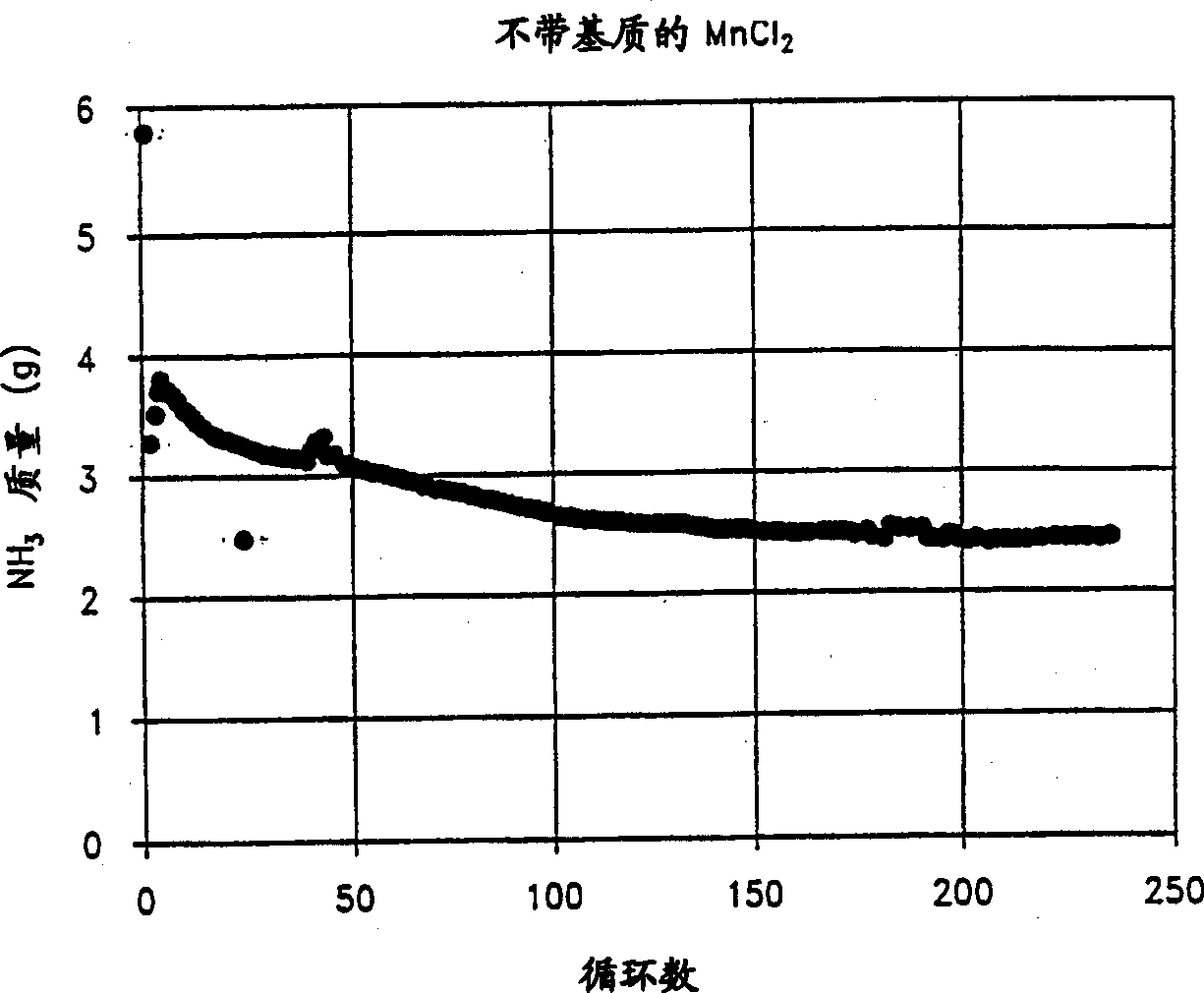

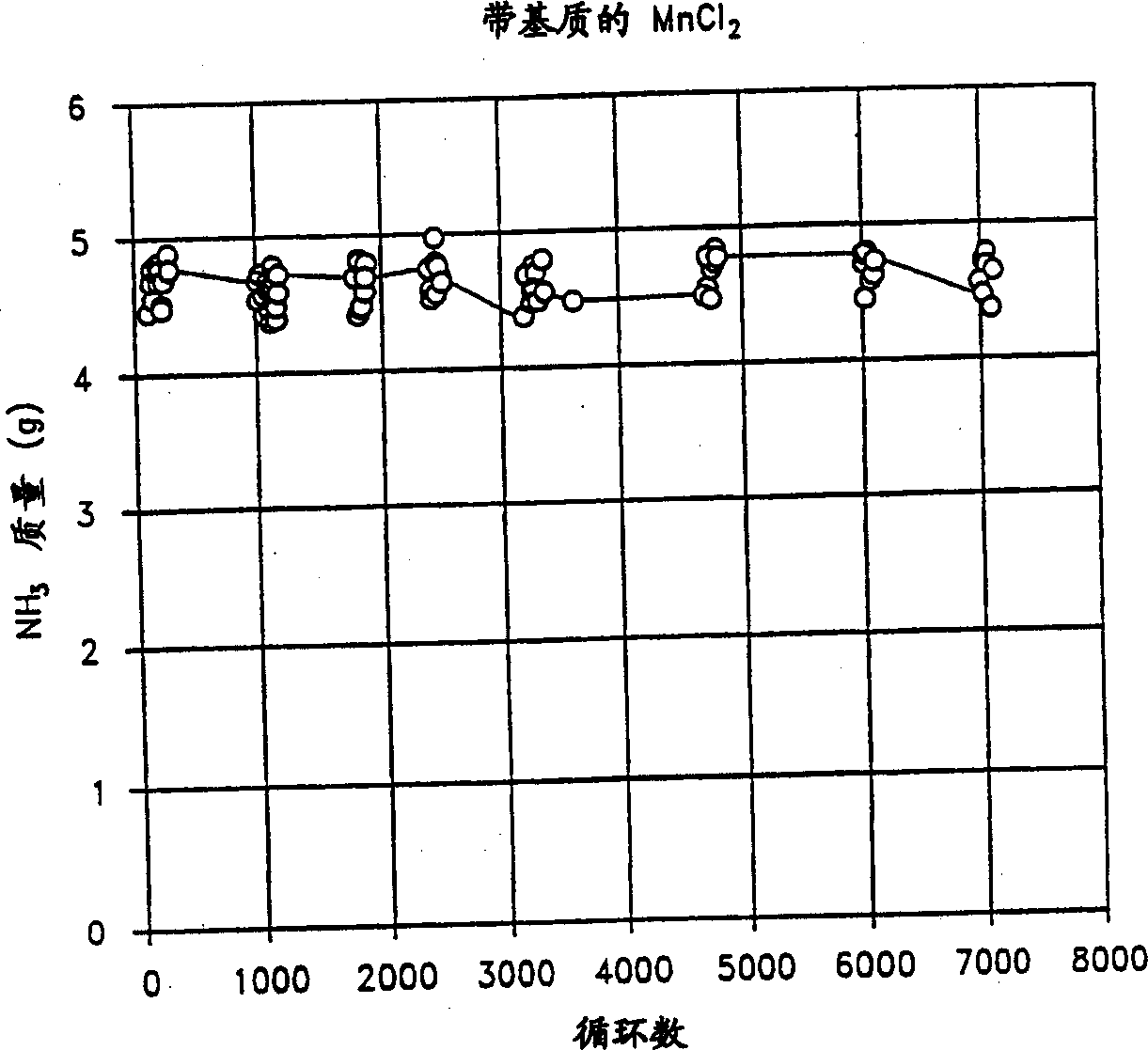

Embodiment 1

[0020] Mix 75.4g of MnCl per 100g of distilled water 2 To prepare matrix felt impregnated with manganese chloride. Slowly add the salt to the water at a temperature below 50°C and mix thoroughly and continuously until the salt is dissolved. The solution was left overnight at room temperature to allow the solids to settle. Carefully remove clear solution by pumping or siphoning slowly near the liquid surface. The 43% MnCl 2 The density of the solution at 25°C is 1.48 g / cm 3 .

[0021] In this solution a single layer of polyphenylene sulfide felt (Ryton(R)), MFM scrimless, is impregnated. The thickness of this felt layer is 0.08in (2mm) and the weight is 18oz / yd 2 (0.061g / cm 2 ). Drain off excess solution and place the single layer of cloth in the oven on a stainless steel rack with a 3mm stainless steel wire mesh upper surface to prevent the wet felt from sagging and to allow for good air circulation. The oven was heated to 200°C and the cloth was dried for 3-4 hrs. D...

Embodiment II

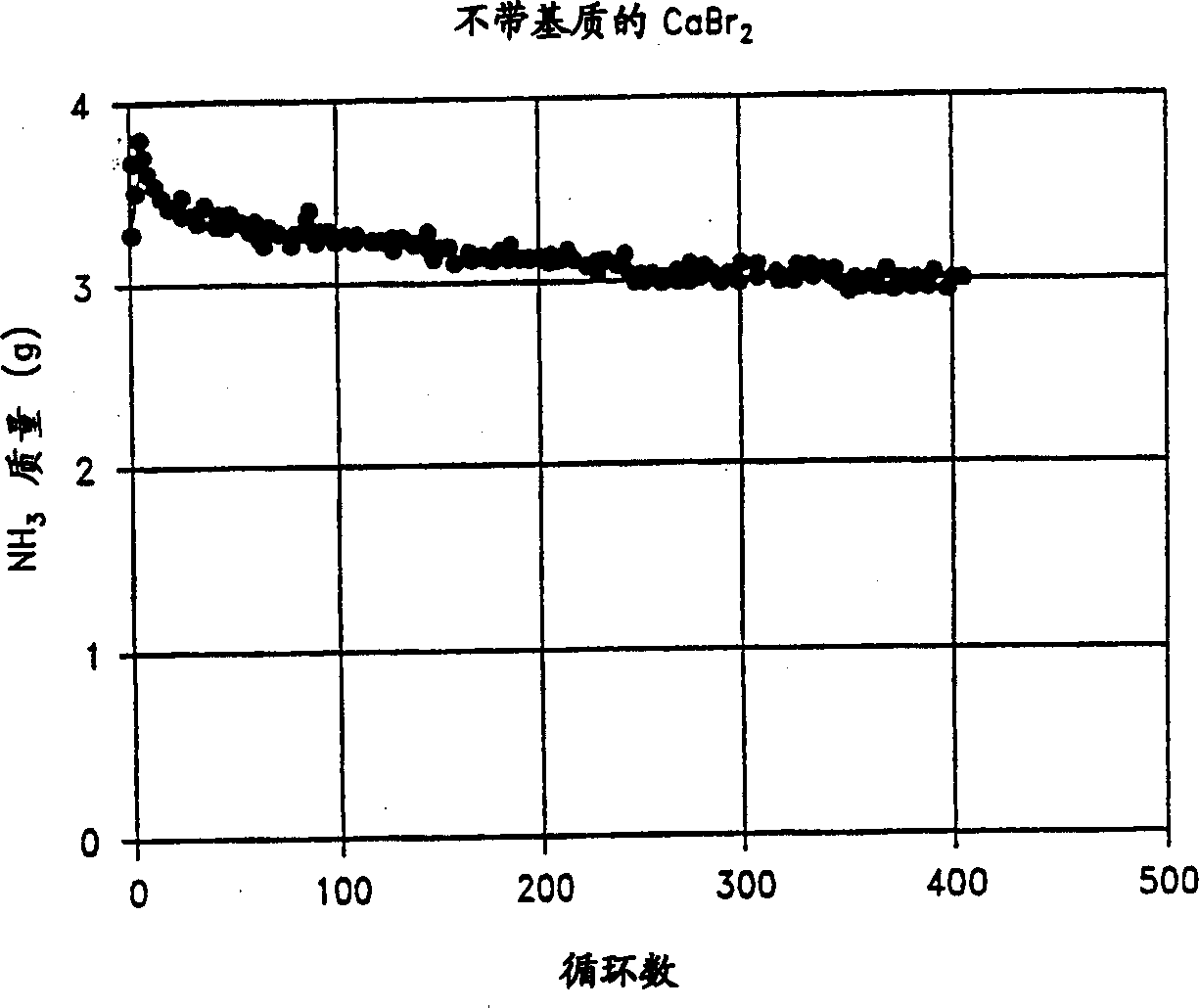

[0023] Mix 81.8g of anhydrous CaBr per 100g of distilled water 2 A 45 wt% solution of calcium bromide was prepared. The salt was added slowly while continuing to mix to prevent the temperature of the solution from exceeding 50°C. Continue mixing until all the salt is dissolved. The solution was left at room temperature to allow the solids to settle out, then the clear solution was carefully removed by siphoning close to the surface. The density of the solution at 25°C is 1.55 g / cm 3 .

[0024] Use 100% Ryton® polyphenylene sulfide needle felt as the substrate, with a thickness of 0.065 to 0.085 inches and a weight of 16 oz / yd 2 , the transmittance is 30~50CFM / ft 2 . The fabric is completely immersed in the calcium bromide solution until it is completely saturated, then the excess solution is drained off. Single layer cloths were dried on a stainless steel rack in an oven at 160°C for 3-4 hrs. After drying, the impregnated slightly tough but not brittle fabric layer is ...

Embodiment III

[0026] Anhydrous salt was slowly added to water with continuous stirring to prepare 43 wt% SrCl 2 For aqueous solution, stir at a rate that prevents the temperature of the solution from rising above 80°C. Avoid vigorous shaking or agitation to prevent unnecessary exposure to air which can cause carbon dioxide to react to form undesired carbonates. Place the solution above 60°C overnight to prevent freezing and allow the solids to settle out. Carefully pump or siphon the clean clear liquid near the surface.

[0027] A single layer Ryton(R) polyphenylene sulfide fabric as used in Example I was heated to 60°C. The heated felt is then dipped into the solution until completely saturated, then drained. Requires about 0.25g solution / cm 2 Felt fully saturates the material. The saturated mat was dried in an oven at room temperature overnight, then at 55°C for 1 hr, at 125°C for 1 hr, and at 160°C for 2 hrs. The dried impregnated felt contains about 61-62 wt% strontium chloride, wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com