Water-transferring patterned paper for ceramics, its making method and its application

A technology of water transfer and decals, applied in the process of producing decorative surface effects, printing of special varieties of printed matter, decorative arts, etc. Difficult to combine organically and other problems, to achieve the effect of stable product quality, low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with embodiment the present invention is described in further detail:

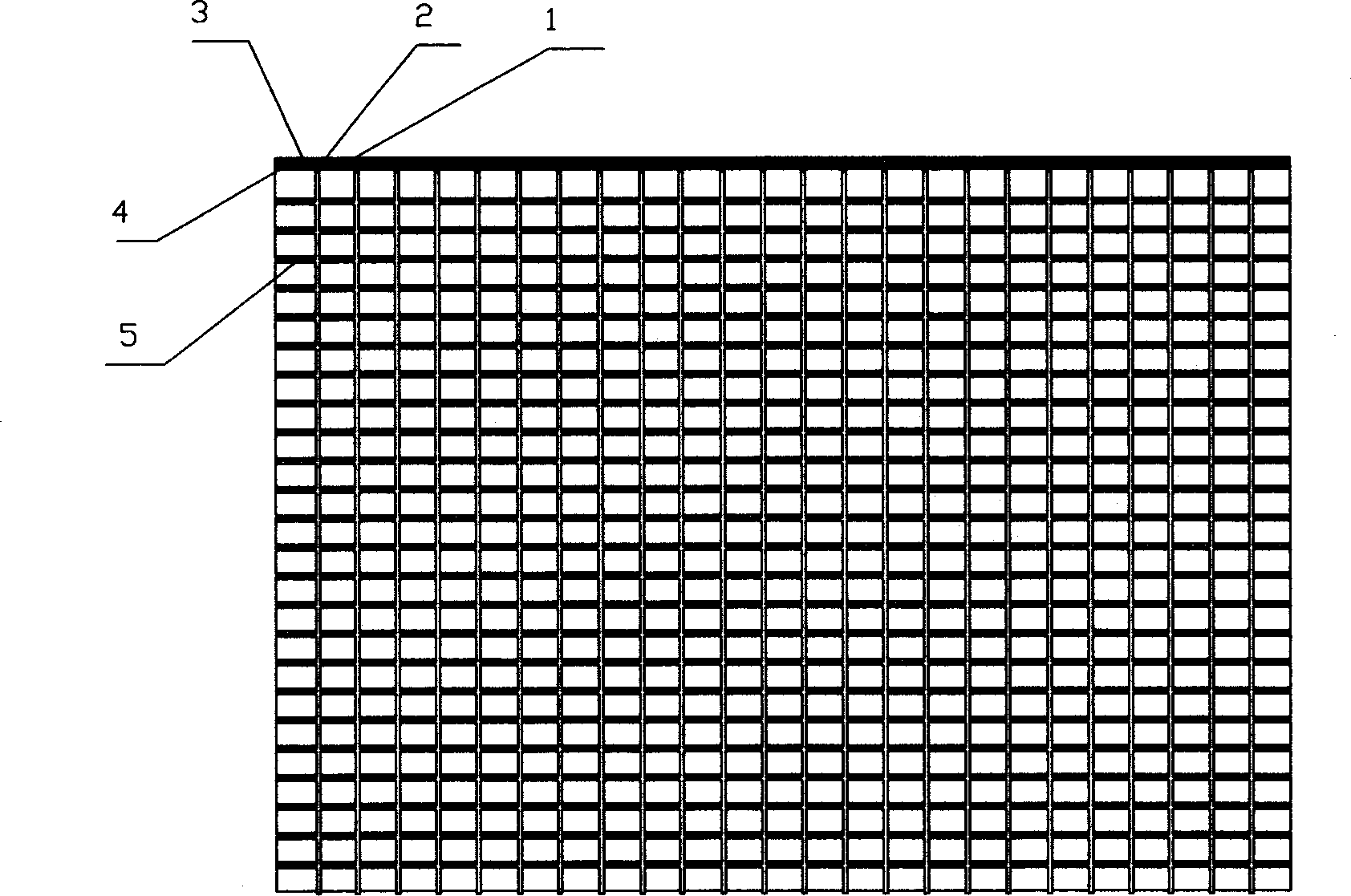

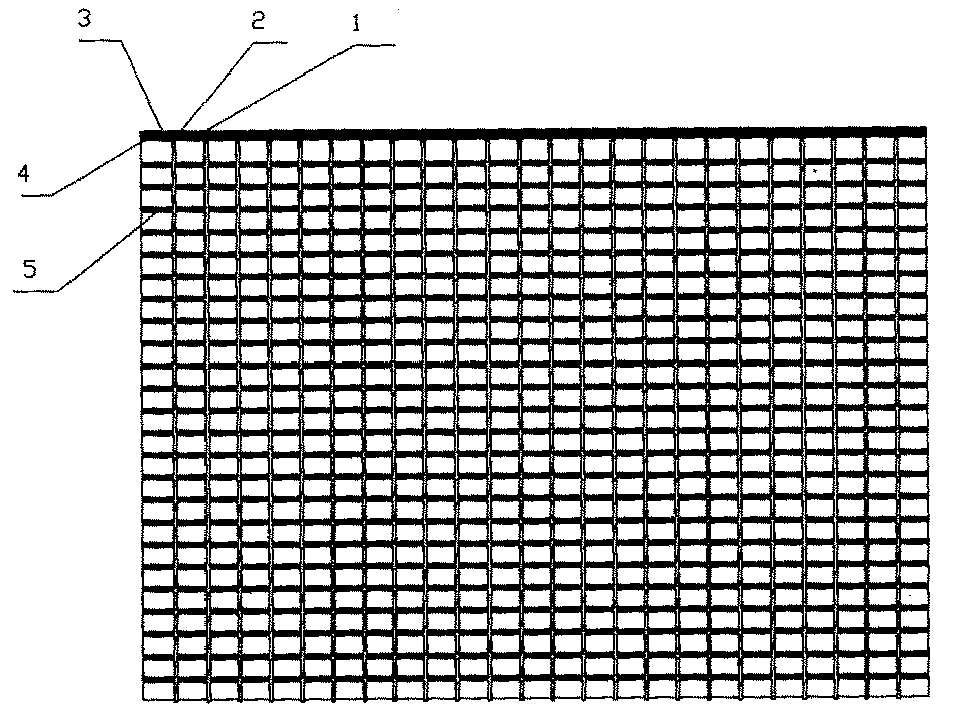

[0031] As shown in the figure, the flower paper of the present invention includes a paper base 2 coated with a hydrosol 1, a stamp 3 printed on the surface of the hydrosol 1, and a base film 4 printed on the stamp 3, forming a pattern of the stamp 3. The ink is mainly composed of inorganic pigments and linking agents. The special feature is that the linking agent is an organic compound with a melting point higher than room temperature but lower than 100°C. The bottom film 4 is an organic compound with a melting point higher than room temperature but lower than 100°C. compound adhesive.

[0032] Here, the linking agent used is ethylene-vinyl acetate copolymer. The ink also contains dibutyl phthalate, and xylene solvent.

[0033] The bottom film 4 is mainly composed of ethylene-vinyl acetate copolymer, dibutyl phthalate, and xylene solvent.

[0034] Also coat one deck omentum 5 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com