Method for reducing textile crease and improving textile contact feel

A tactile and wrinkled technology, applied in chemical instruments and methods, textiles and papermaking, improved hand-feeling fibers, etc., can solve problems such as low durable pressure performance and lack of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

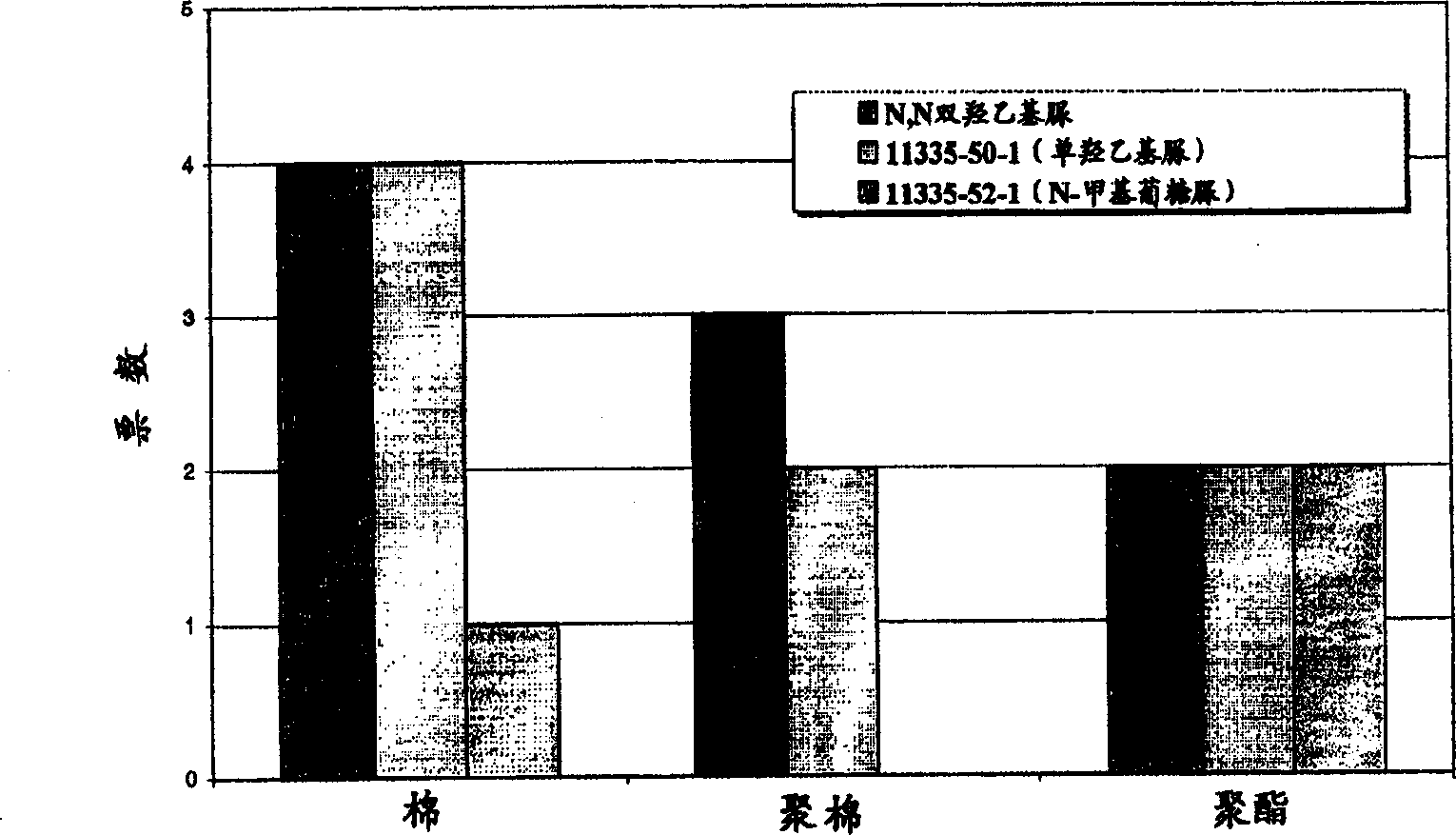

Image

Examples

Embodiment 1

[0036] 106.2 g of diethanolamine and 61.24 g of urea were charged to a 250 ml flask equipped with a condenser, thermometer, stirrer and nitrogen purged probe. The mixture was heated to 115°C for 5 hours. A nitrogen purge is used to remove the ammonia that is produced. The reaction process was monitored by titrating the remaining diethanolamine with 0.1N hydrochloric acid. A clear liquid was obtained, containing N,N-bis (2-hydroxyethyl)urea.

[0037] The following amines in Examples 2-7 were reacted with urea according to the procedure in Example 1.

[0038] Weight Urea Example Amine g g ethanolamine 61 603 3-amino-1-propanol 150 604 2-amino-2-ethyl-1,3-propanediol 119 30

[0039] (AEPD)

[0040] Ethanolamine 122 606 Diethanolamine 210 607 4-Aminobutanol 12 4

Embodiment 8

[0042] 212.4 g diethanolamine in 212.4 g water, neutralized to pH 4 with 101.85 g concentrated sulfuric acid. A solution of 168.99 g of potassium cyanate in 260 g of water was then added and the mixture was heated to 90°C for 3 hours. After cooling to ambient temperature, potassium sulfate precipitated out and was filtered. The filter cake was washed with 425 g of hot ethanol. The recovered ethanol is added to the filtrate to make the filtrate cloudy. The white precipitate was removed by filtration, and then the ethanol was evaporated to obtain a viscous liquid solution of N,N-bis(2-hydroxyethyl)urea. The product can be obtained by neutralizing the amine with another acid, such as sulfuric acid. Other cyanates may also be used, such as sodium cyanate.

Embodiment 9

[0044] According to the steps of Example 8, 195.22 g of N-methyl-D-glucosamine in 200 g of water was reacted with 98.08 g of sulfuric acid. After adjusting the pH to 4, 81.11 g of potassium cyanate was added to the flask containing 100 g of water. The mixture was heated to 70°C for 2 hours. After cooling to 0°C, the by-product precipitated potassium sulfate was removed by filtration. The filtrate was treated with 250 mL of hot methanol and filtered to remove residual salt by-products. Methanol was distilled off in vacuo to obtain a solution containing N-methyl-D-glucuronide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com