Ceramic electronic element

A technology of electronic parts and ceramics, which is applied in the field of ceramic electronic capacitors and can solve the problem of high heating temperature of ceramic bodies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

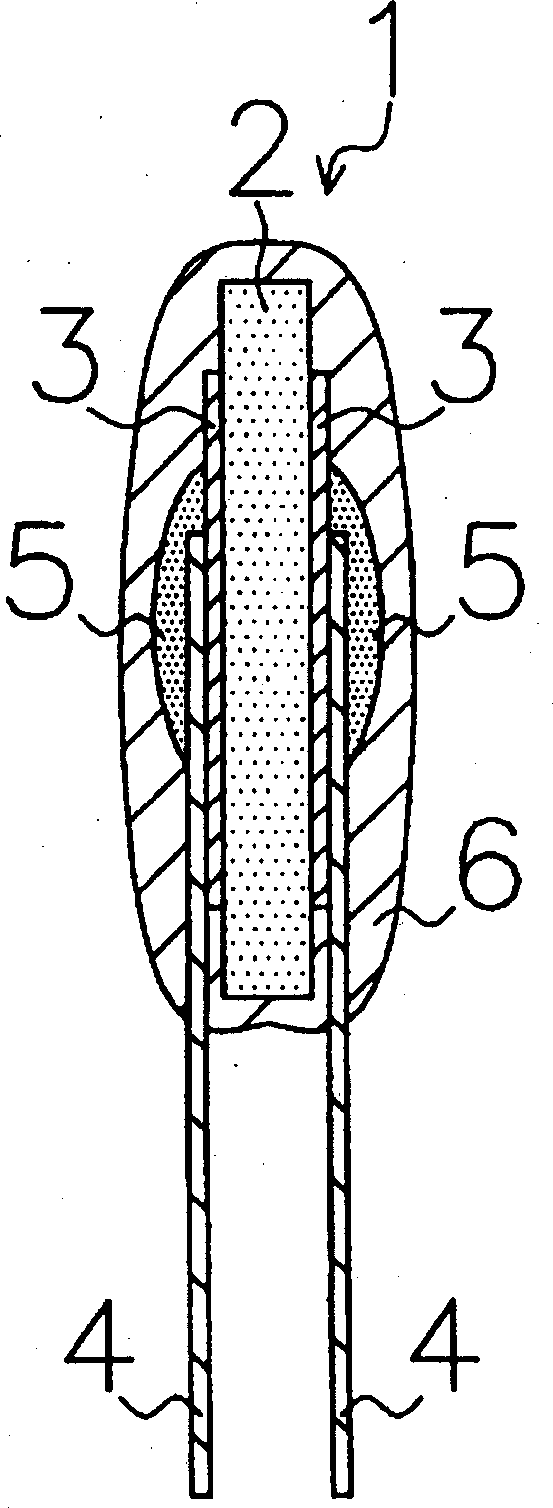

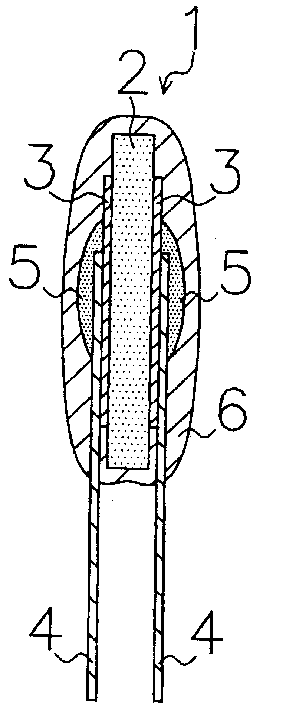

Image

Examples

Embodiment

[0025] Next, as a conductive component, 33% by volume of Ag powder with a particle size of 0.1 to 5 microns, 6% by volume of glass powder of samples 1 to 9, and 61% by volume of excipients were mixed, and ground with a three-roll mill. After grinding, the conductive pastes of samples 1-9 were obtained. As the excipient, a solution prepared at a ratio of 80% by weight of terpineol and 20% by weight of ethylcellulose was used.

[0026] Next, screen-print the conductive pastes of samples 1 to 9 with a 3mm diameter template on both main surfaces of a ceramic body made of barium titanate with a target capacitance of 1nF, and heat it in air at 800°C for 2 hours. The condition of sintering to form the terminal electrodes, and 200 test samples of samples 1 to 9 were produced respectively.

[0027] Here, the penetration depth of the glass from the surface of the ceramic body was measured for each of 100 samples of test samples 1 to 9, and the measurement results are summarized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com