Pattern etching agent of In-Sn oxide and LCD making process

A technology of indium tin oxide and etchant, which is applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, transistors, etc., and can solve problems such as degradation of liquid crystal display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

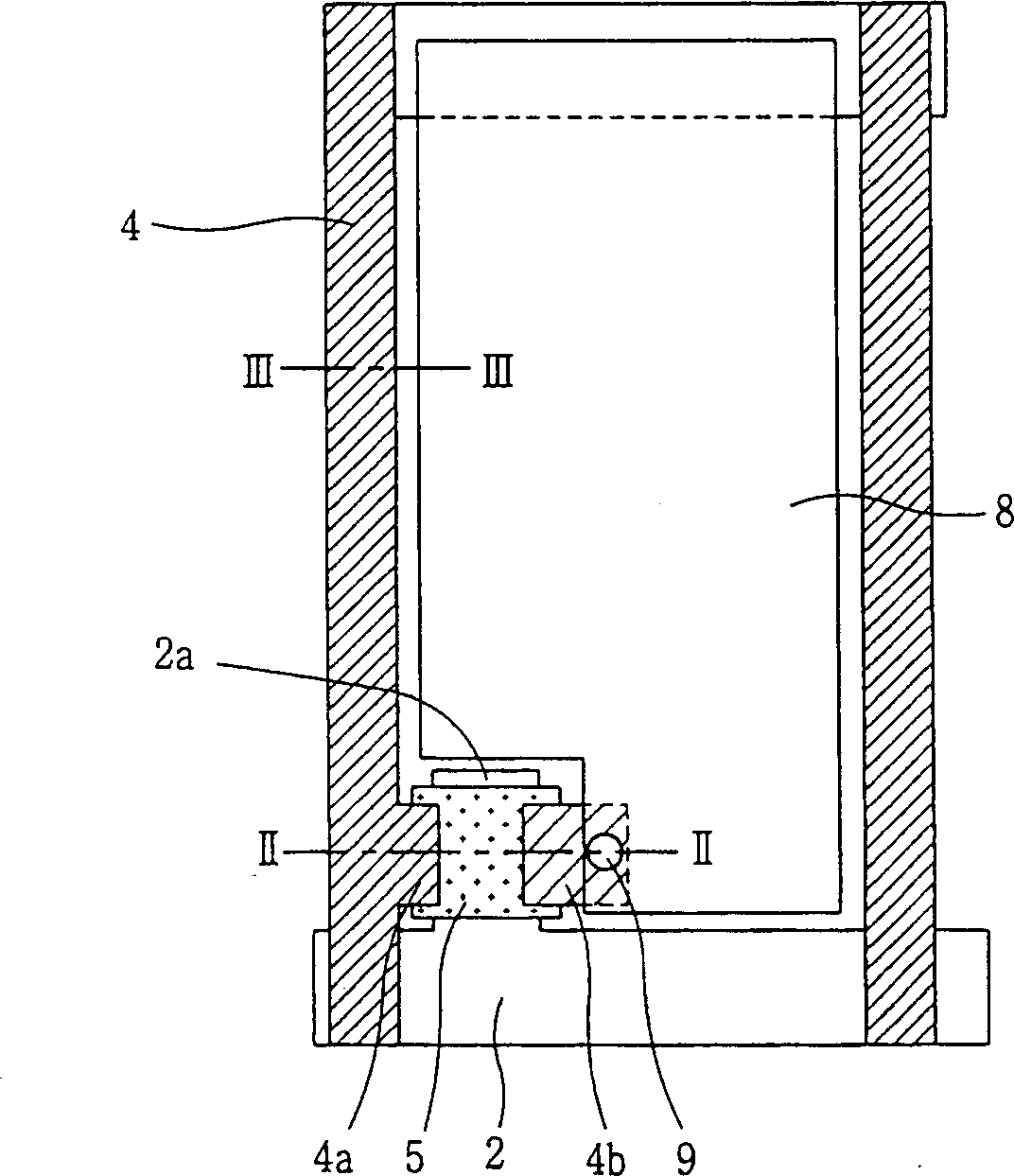

[0039] Embodiments of the present invention will be described in detail below with reference to examples illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

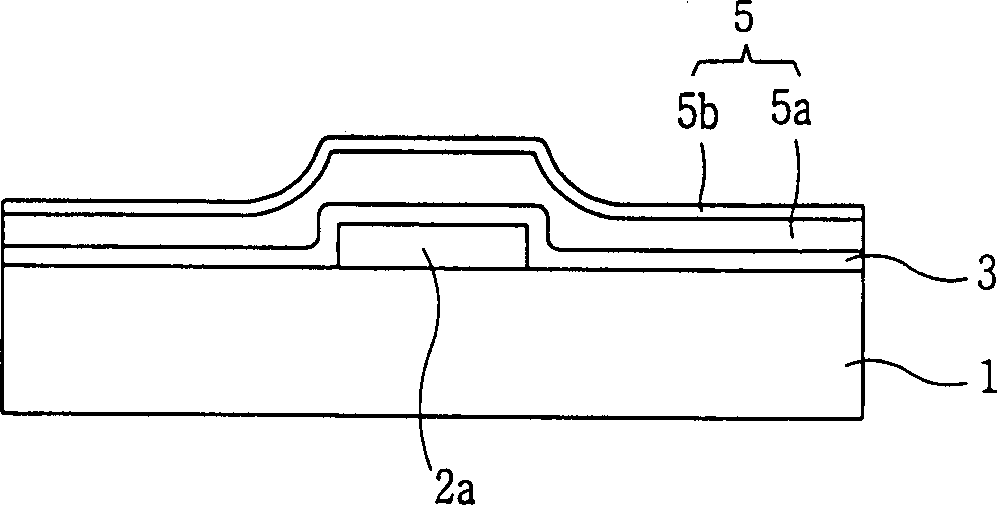

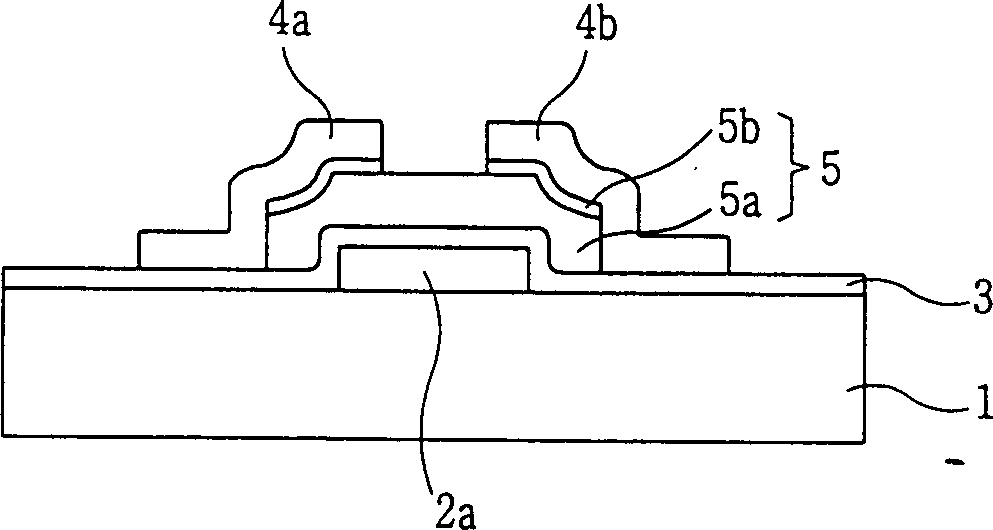

[0040] Figures 4A to 4D is a diagram illustrating the process by using the ITO etchant according to the present invention along the figure 1 Sequential sectional view of line II-II;

[0041] Such as Figure 4A A gate electrode 2a is formed on a glass substrate 1 as shown. On the gate electrode 2a including the substrate 1, the gate insulating film 3, amorphous silicon 5a and n + Amorphous silicon 5b.

[0042] exist Figure 4B , by patterning amorphous silicon 5a and n + Amorphous silicon 5 b forms the active region 5 . The source electrode 4a and the drain electrode 4b are formed separately from each other on the active region 5 (including the side surface of the active region 5). Mo or Mo alloy is depos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com