Prepn. of submicron high-purity transparent alumina ceramic material

A sub-micron technology for alumina ceramics, which is applied in the field of preparation of transparent alumina ceramic materials, and can solve the problems of large crystal grains of transparent alumina ceramics, affecting light transmission performance, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Commercial α-Al with a purity of 99.99% was processed by 50MPa dry pressing and 200MPa cold isostatic pressing 2 o 3 (The same below) Raw material powder molding; Then the molded green body was pre-sintered without pressure at 1200 ° C for 400 minutes; the pre-fired green body was placed in a hot isostatic pressing furnace for post-treatment under an Ar gas atmosphere, and the temperature was 1250°C, pressure 140Mpa, heat preservation and pressure holding time 40 minutes; finally use a surface grinder and diamond abrasive paste to grind and polish the ceramic surface.

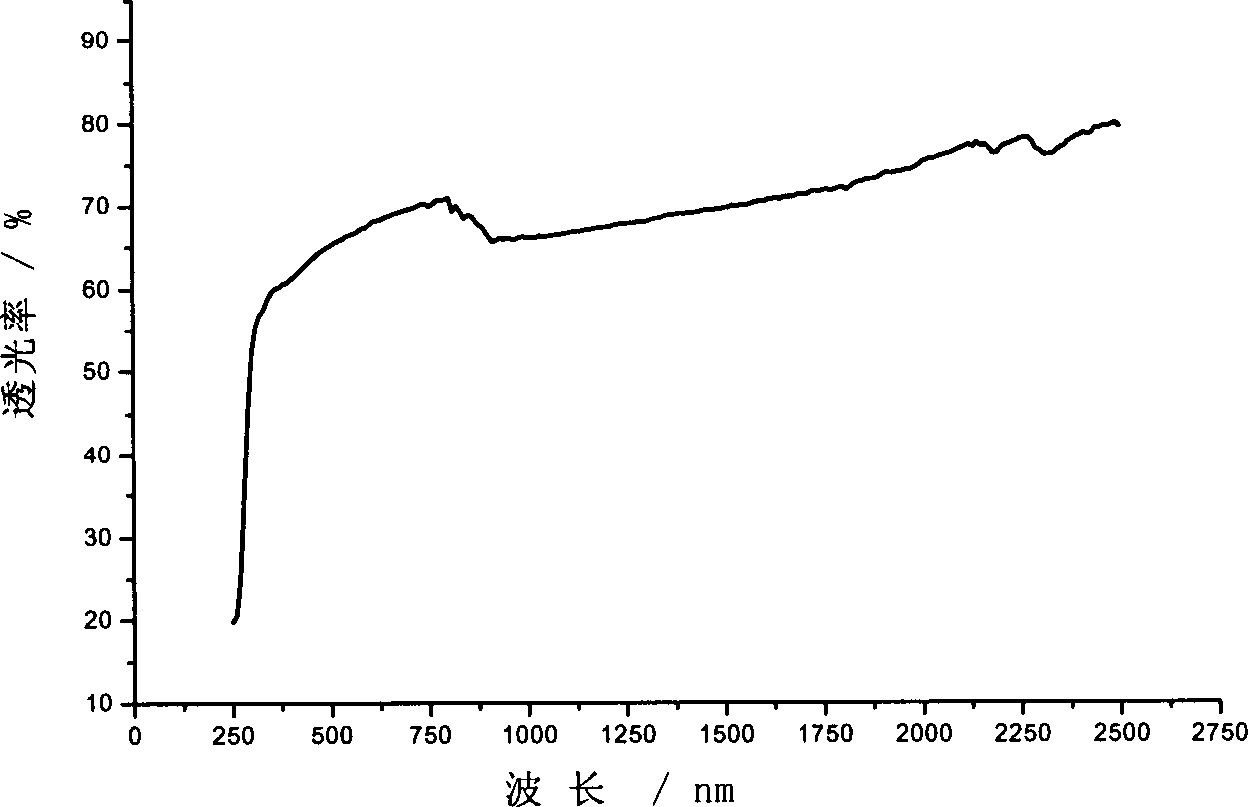

[0017] The relative density of the obtained ceramic body was 99.9%, and the average grain size was 0.68 μm. The results of the transmittance test are as follows figure 1 Shown: the transmittance can reach 70% in the visible light region (380nm~760nm), and 80% in the infrared light region (>760nm). At the same time, in the ultraviolet light region (<380nm), the transmittance ratio of the material presen...

Embodiment 2

[0019] Using 50MPa dry pressing plus 200MPa cold isostatic pressing process to shape the raw material powder; then pre-sinter the molded green body at 1250°C for 90 minutes without pressure; put the pre-fired green body into a hot isostatic pressing furnace under Ar The post-treatment is carried out under the air atmosphere, the temperature is 1200°C, the pressure is 140Mpa, and the time of heat preservation and pressure holding is 40 minutes; finally, the ceramic surface is ground and polished with a surface grinder and diamond grinding paste.

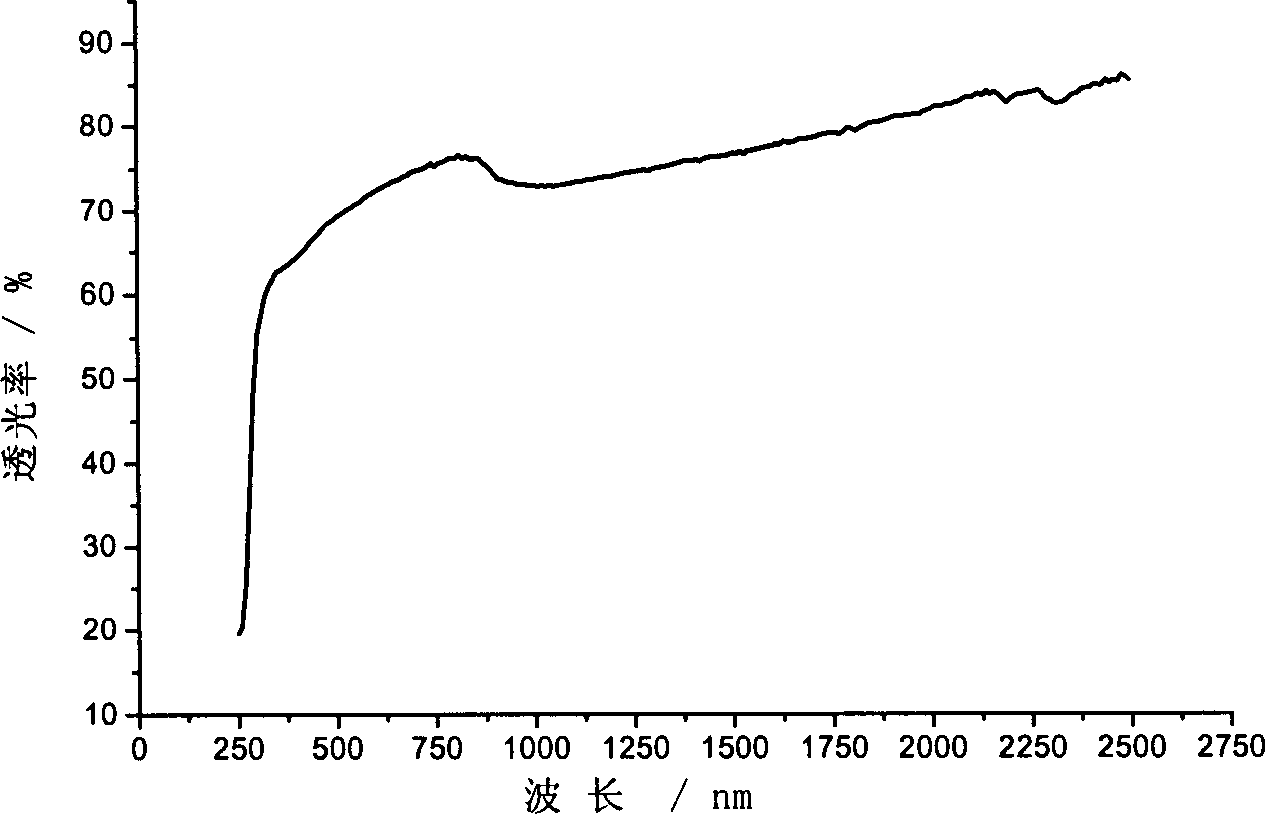

[0020] The relative density of the obtained ceramic body was 99.95%, and the average grain size was 0.63 μm. The results of the transmittance test are as follows figure 2 Shown: in the visible light region (380nm~760nm), the transmittance can reach 75%, while in the infrared region (>760nm) it can reach more than 85%. Similarly, in the ultraviolet region (<380nm), the transmittance ratio of the material It shows a straight-line down...

Embodiment 3

[0022] The raw material powder is molded by 50MPa dry pressing plus 200MPa cold isostatic pressing; then the molded green body is pre-sintered without pressure at 1350°C for 30 minutes; the pre-sintered green body is placed in a hot isostatic pressing furnace under Ar The post-treatment is carried out under an air atmosphere, the temperature is 1350°C, the pressure is 140Mpa, and the time of heat preservation and pressure holding is 40 minutes; finally, the ceramic surface is ground and polished with a surface grinder and diamond grinding paste.

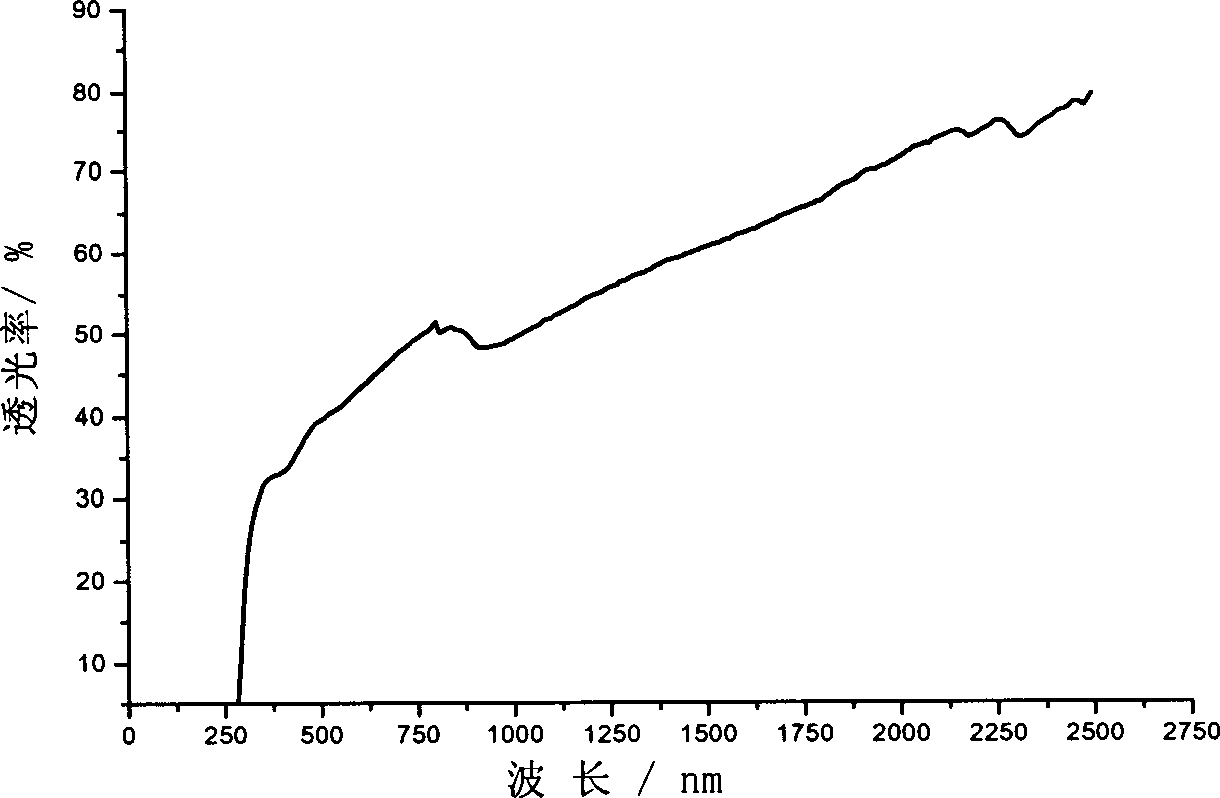

[0023] The obtained ceramic body has a relative density of 99.95% and an average grain size of 1 μm. The results of the transmittance test are as follows image 3 As shown: the transmittance can reach 50% in the visible light region (380nm~760nm), and can reach more than 80% in the infrared region (>760nm). Due to the large grain size, the sample prepared by this process is transparent Light performance is lower than the previous tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com