Biological material using electrostatic attraction layer-layer self-assembled modified polyester material as surface with cell compatibility

A technology of layer-by-layer self-assembly and modification of polyester, applied in the fields of nanotechnology, nanomedicine, medical science, etc. for materials and surface science, can solve the inflammatory response of surrounding organs and tissues, unsuitable scaffold materials and products, Can not provide tissues and organs and other problems to achieve the effect of reducing inflammation, improving cytocompatibility, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031] Poly(L-lactic acid) was dissolved in 1,4-dioxane (the polylactic acid content was 3% by weight), and cast in a film-forming mold to form a film. The poly(L-lactic acid) membrane was immersed in a 1,6-hexanediamine / n-propanol solution with a concentration of 0.06 g / mL, reacted at 50°C for 8 minutes, soaked and cleaned with deionized water, and dried under vacuum. Take a small piece of membrane in a ninhydrin solution with a concentration of 1.0mol / L, and detect the presence of free amine groups (-NH 2 ).

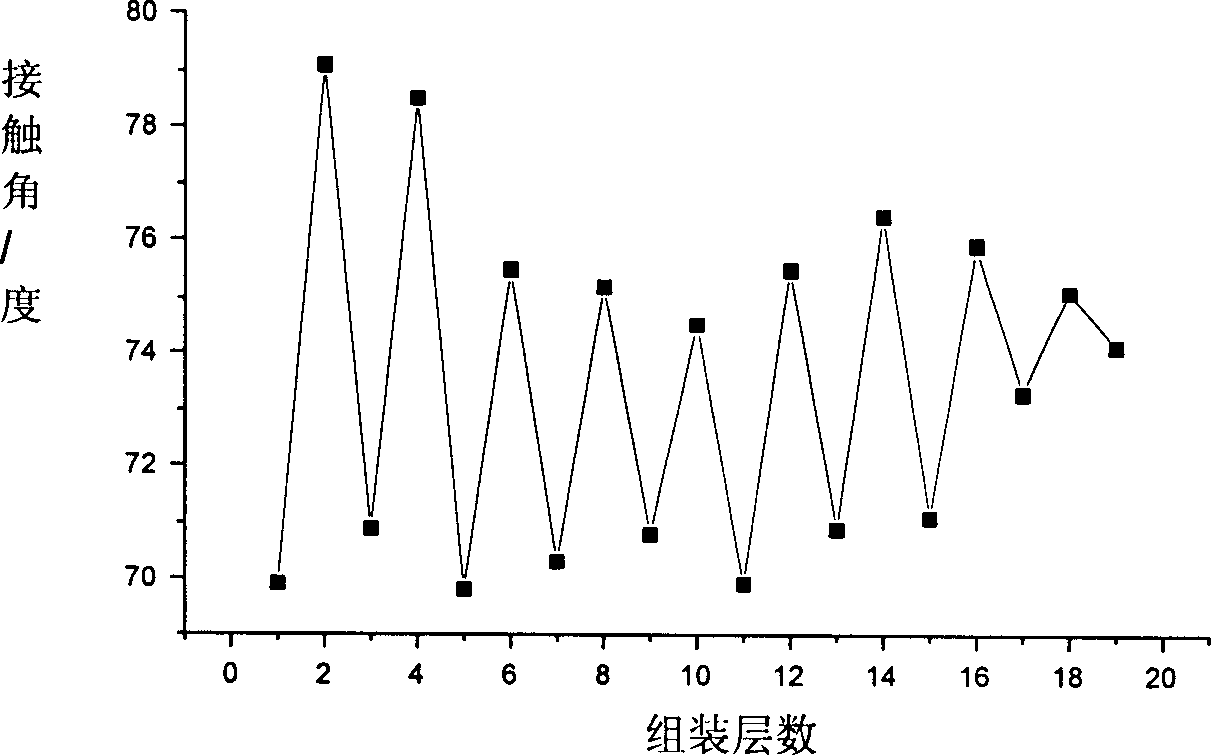

[0032] The above-mentioned poly(L-lactic acid) film with free amine groups on its surface was immersed in hydrochloric acid with a concentration of 0.012mol / L for acidification for 15 minutes, taken out and rinsed with triple distilled water, then immersed in 1.0 mg / ml sodium polystyrene sulfonate ( PSS) solution for 20 minutes, rinsed with triple distilled water and blown dry with nitrogen, then soaked in 1.0mg / ml chitosan acetic acid solution for 15 minutes, rinsed ...

example 2

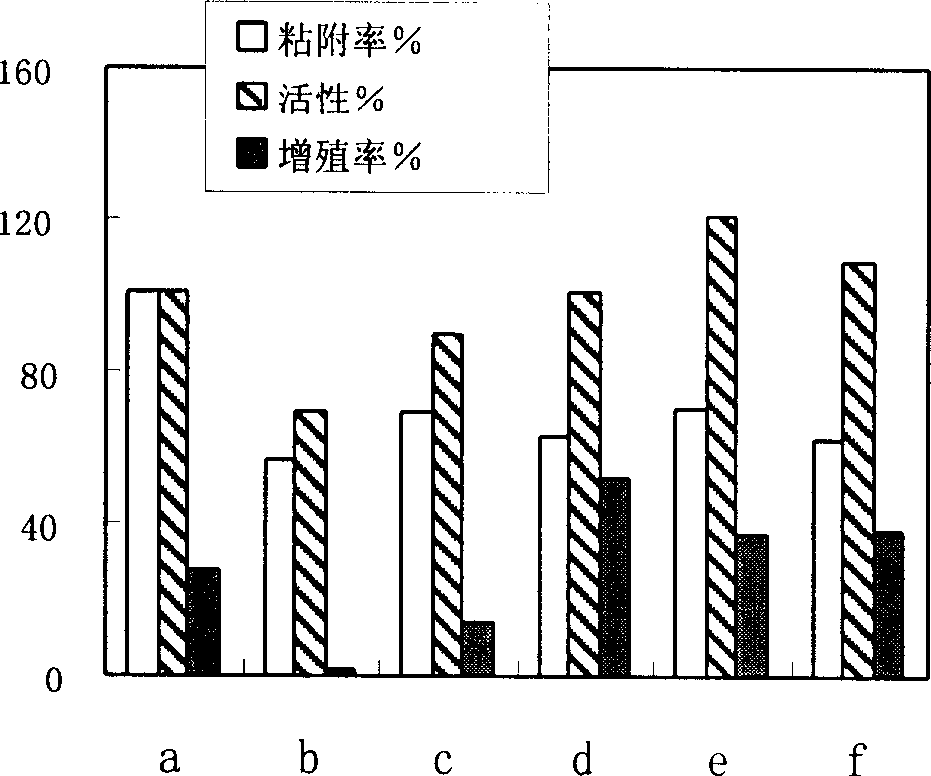

[0035] The polyester polyurethane was dissolved in N,N-dimethylformamide to make the concentration of the polymer solution reach 0.13 g / mL, and the solution was cast in a film-forming mold to form a film. The polyester polyurethane film was immersed in 1,6-hexanediamine / n-propanol solution with a concentration of 0.06 g / ml, reacted at 37° C. for 5 minutes, rinsed with triple distilled water, and vacuum-dried to constant weight. Take a 2 cm long and 1 cm wide aminolytic polyester polyurethane, soak it in ninhydrin / absolute ethanol solution with a concentration of 1.0mol / L for 1 minute, take it out, and heat it at 80°C, the surface of the film shows obvious blue-purple, indicating the presence of free amine groups (-NH 2 ). Immerse the above-mentioned polyester polyurethane film with free amine groups on its surface into hydrochloric acid with a concentration of 0.012mol / l to acidify for 15 minutes, take it out and rinse it with triple distilled water, and then add it to hepari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com