Themally insulating and reducing composite paint and its preparing process and application

A technology of thermal compounding and heat insulation layer, which is applied in coatings, conjugated diene coatings, polyester coatings, etc., can solve the problems of unsatisfactory light reflection effect of the coating surface layer, reduced heat absorption, and unsatisfactory requirements. Achieve good heat insulation and heat reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 100 parts by weight of styrene acrylate emulsion with a solid content of about 45% (weight), 15 parts by weight of talcum powder, 10 parts by weight of light calcium carbonate, 5 parts by weight of hollow glass beads, 5 parts by weight of titanium dioxide, dibutyl hydroxytoluene 3 parts by weight, 1 part by weight of ethylene glycol and 10 parts by weight of water glass are fully stirred evenly, and coated on the substrate to form a heat-insulating layer. With 100 parts by weight of alkyd resin, 120 # 20 parts by weight of solvent gasoline and 10 parts by weight of aluminum paste are evenly mixed and sprayed on the heat-insulating layer to form a reflective heat-reducing layer. After both layers are cured, the heat-insulating and heat-reducing composite coating of the present invention is formed.

Embodiment 2

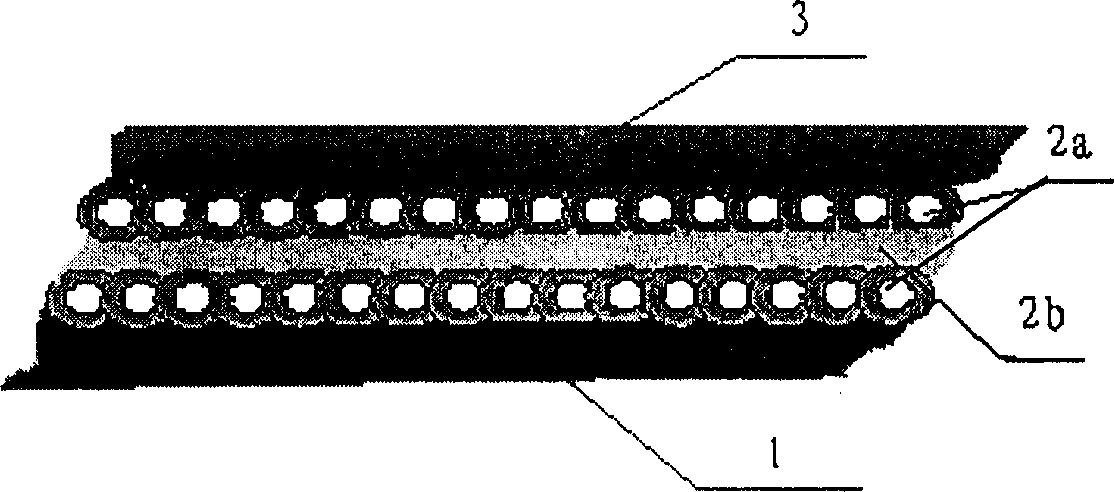

[0032]100 parts by weight of styrene acrylate emulsion with a solid content of about 45% (weight), 10 parts by weight of light calcium carbonate, 2 parts by weight of sodium bentonite, 8 parts of fly ash hollow microspheres, 2,6-di-tert-butyl 1 part by weight of p-phenol, 5 parts of water glass, fully stirred evenly. Brush on the surface of the substrate to form a thermal insulation layer. 100 parts by weight of polyacrylate emulsion with a solid content of about 50% (weight), 30 parts of mica powder, 15 parts by weight of hollow glass beads, 5 parts of talcum powder, 8 parts of propylene glycol, and polyacrylic acid with a concentration of about 15% (weight) After fully stirring 8 parts of sodium aqueous solution, it is sprayed on the surface of the cured heat insulation layer to form a reflective and heat-reducing layer.

Embodiment 3

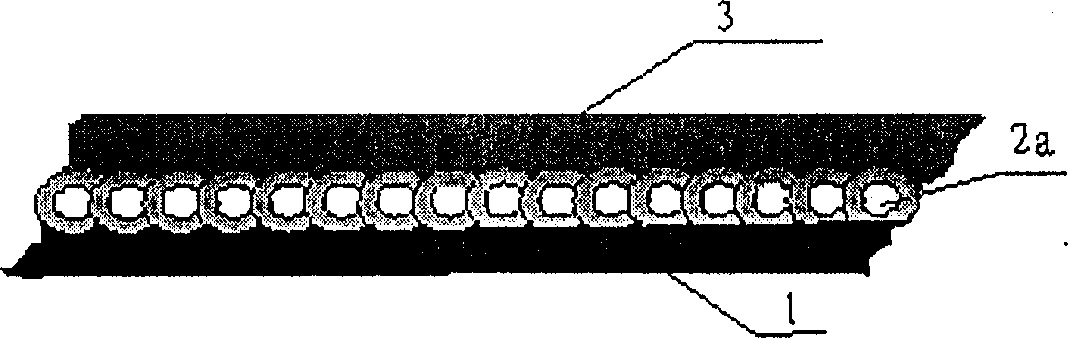

[0034] 100 parts by weight of acrylic pressure-sensitive adhesive emulsion with a solid content of about 40% (weight), 2 parts by weight of sodium bentonite, 5 parts by weight of titanium dioxide, 1 part by weight of antioxidant 264 and 1 part by weight of ethylene glycol are uniformly blended into a pressure-sensitive latex , sprayed on the surface pretreated substrate to form a pressure-sensitive adhesive layer, and then spray 7 parts by weight of hollow microspheres to form a multilayer arrangement of hollow microspheres heat insulation layer; then coat the described in Example 1 Reflective heat reducing layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com