Konjaku plucosidopolyose graft copolymer, preparing process and use thereof

A technology of konjac glucosidan and graft copolymer, which is applied in the field of konjac glucosidan graft copolymer and its preparation and application, can solve the problems of limited application, improve the emergence rate, and promote the formation of aggregate structure , the effect of shortening the emergence cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

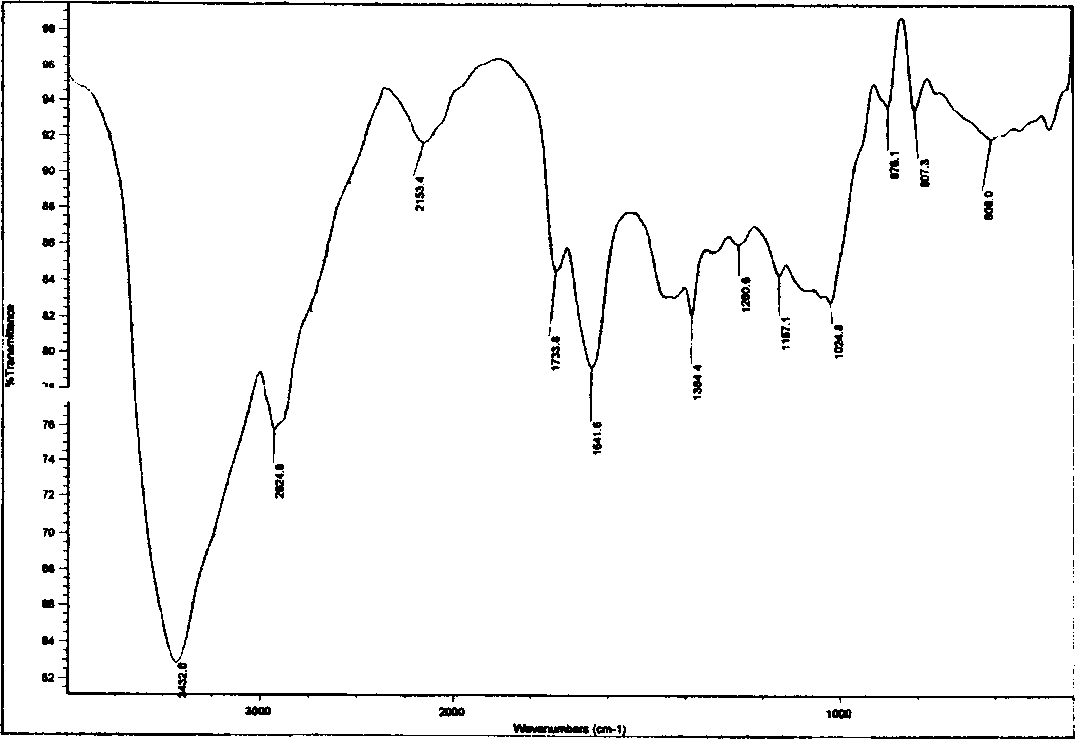

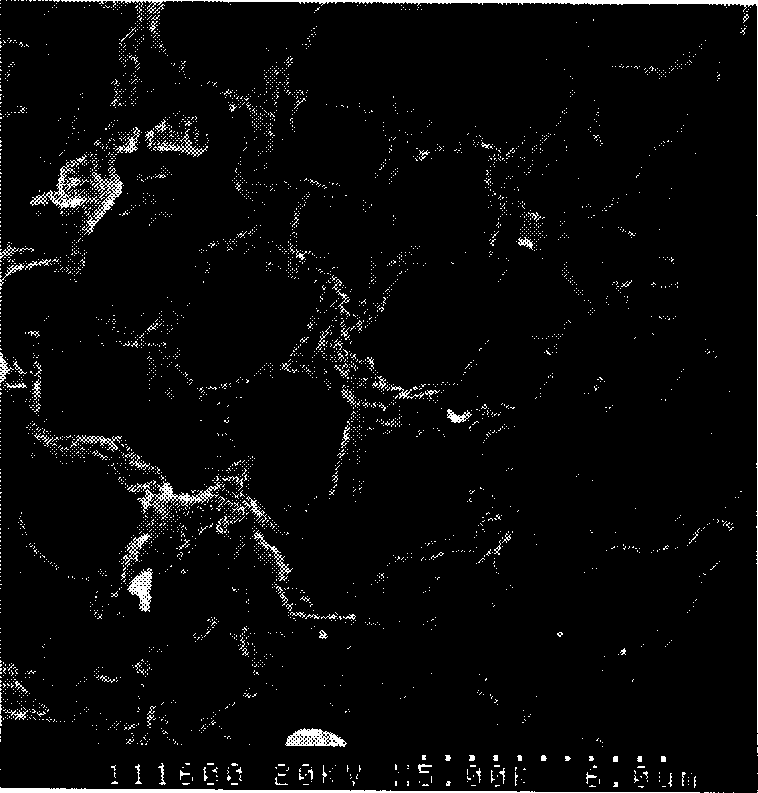

[0037] Embodiment one: the synthesis of konjac glucomannan / acrylic acid graft copolymer

[0038] Accurately weigh 0.10 g of konjac fine powder, prepare an aqueous solution with a concentration of 0.5%, and place it at about 50°C for a sufficient time to make the KGM disperse evenly, then add 1.77 mol / liter of acrylic acid monomer, stir well and then add 2.19 mmol / liter of initiator solution (cerium ammonium nitrate + nitric acid) and 10.37 mmol / liter of cross-linking agent N, N'-methylenebisacrylamide, stir well and stop the reaction after reacting at 45-50 ° C for 2 hours , to obtain a colorless and transparent hydrogel.

[0039] The hydrogel obtained by the reaction was soaked with distilled water, washed, and then dried at 60° C. to obtain a crude product. Then the dried product was extracted with acetone in a Soxhlet extractor for 24 hours to remove the homopolymer, and dried at 60°C to obtain the desired pure graft copolymer, which was stored for future use. Determi...

Embodiment 2

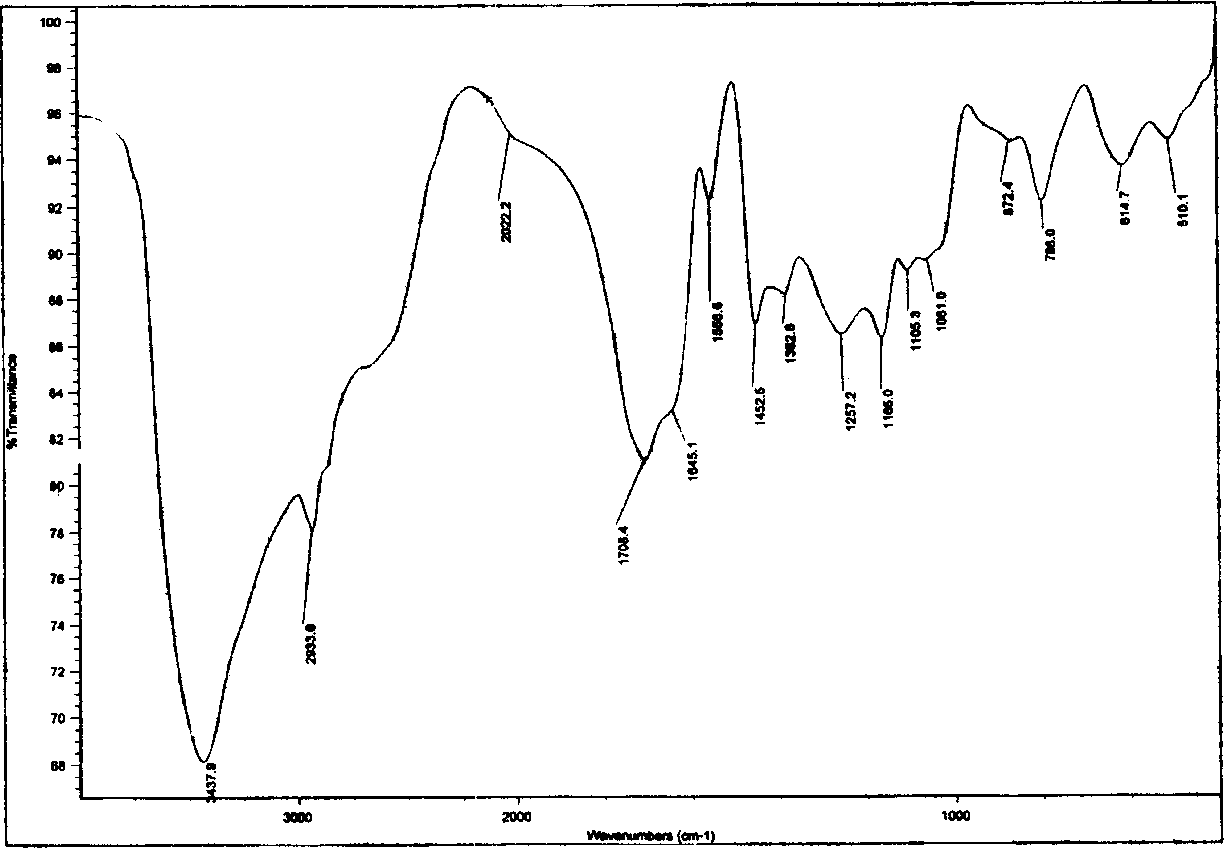

[0052] Embodiment two: the synthesis of konjac glucomannan / methacrylic acid graft copolymer

[0053] Accurately weigh 0.20 g of konjac fine powder, prepare an aqueous solution with a concentration of 1.0%, and place it at about 50°C for sufficient time to make the KGM disperse evenly, then add 1.77 mol / liter of methacrylic acid monomer, stir well and then add 2.19 Initiator solution (cerium ammonium nitrate + nitric acid) and N, N'-methylenebisacrylamide with 10.37 mmol / L crosslinking agent, stir well and react at 45-50°C for 2 hours Stop the reaction to obtain a colorless and transparent hydrogel.

[0054] The hydrogel obtained by the reaction was soaked with distilled water, washed, and then dried at 60° C. to obtain a crude product. Then the dry product was extracted with acetone in a Soxhlet extractor for 24 hours to remove the homopolymer, and dried at 60°C to obtain a pure graft copolymer.

Embodiment 3

[0055] Embodiment three: the synthesis of konjac glucomannan / acrylamide graft copolymer

[0056] In a three-necked flask with a stirrer, add 0.20 g of konjac fine powder and water, stir to make a 0.5% aqueous solution and keep warm at 50 ° C to make the konjac fine powder evenly dispersed, and nitrogen is introduced, and 0.12 g of cerium ammonium nitrate is added (dissolved in nitric acid), after stirring for 20 minutes, add 10 grams of acrylamide and 0.17 grams of N, N'-methylenebisacrylamide, and stop the reaction after 2.5 hours to obtain a gel.

[0057] The hydrogel obtained by the reaction was soaked with distilled water, washed, and then dried at 60° C. to obtain a crude product. Then the dry product was extracted with acetone in a Soxhlet extractor for 24 hours to remove the homopolymer, and dried at 60°C to obtain a pure graft copolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com