Polarizing plate

A polarizing film and adhesive technology, applied in polarizing elements, optics, instruments, etc., can solve difficult problems such as color tone change and light leakage suppression, and achieve the effect of small photoelastic coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

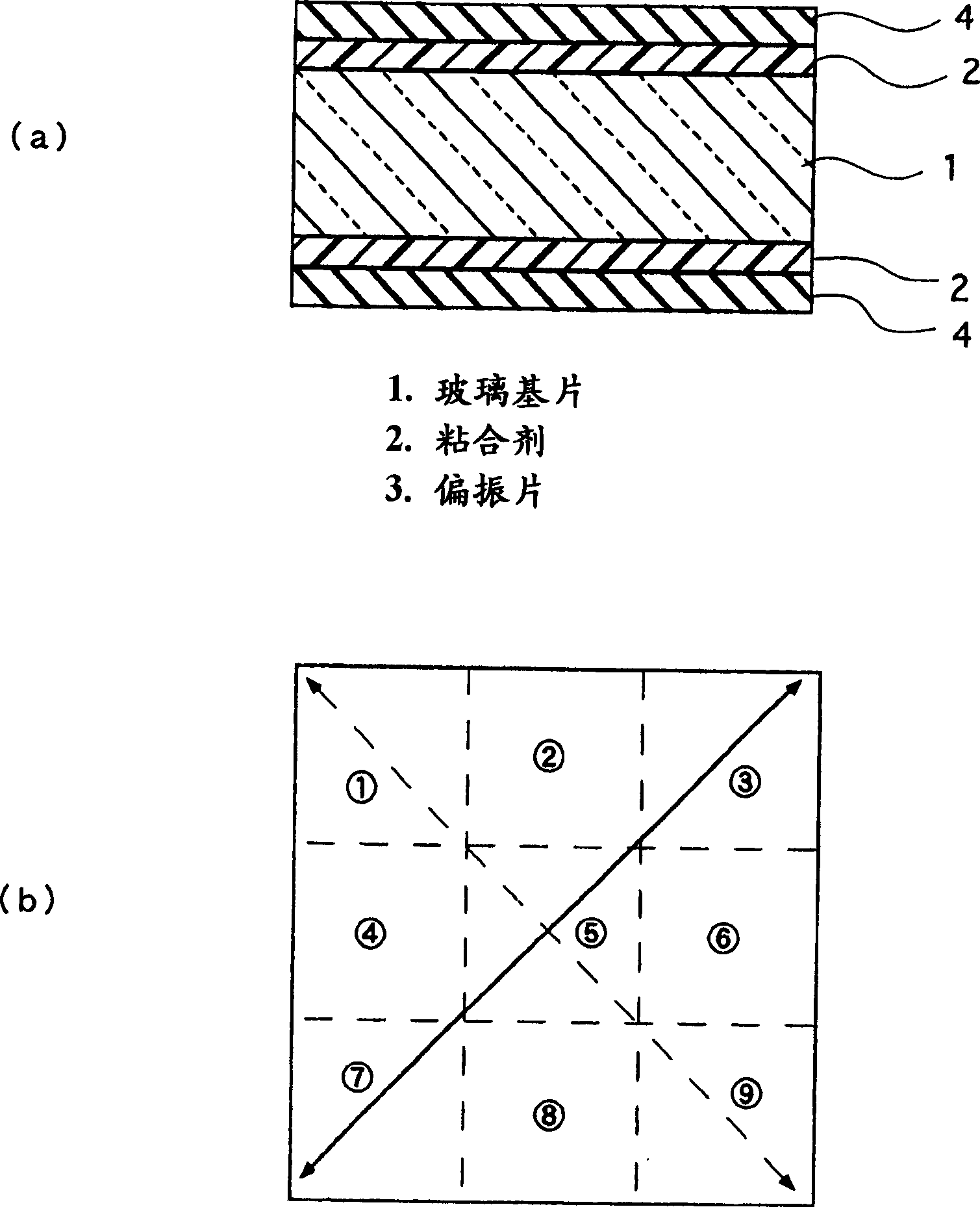

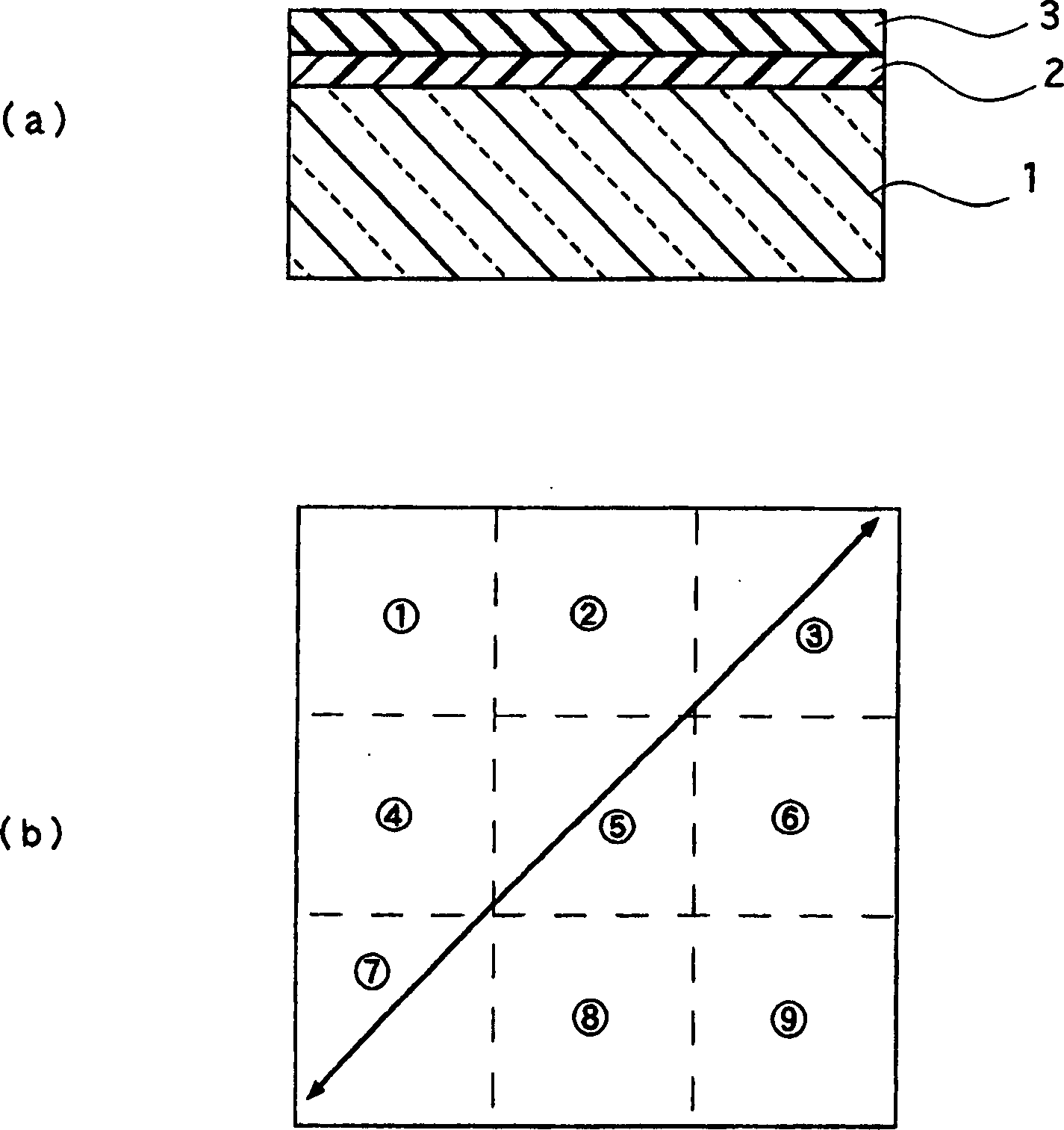

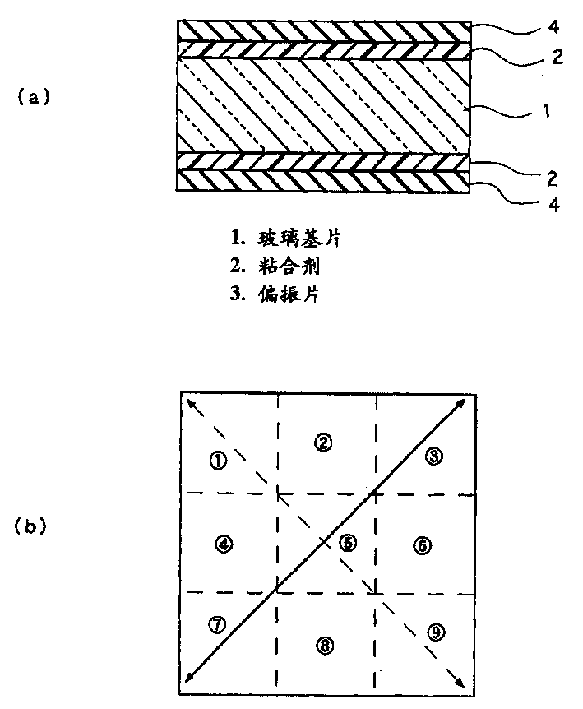

Image

Examples

Embodiment 1

[0081] 25 parts by weight of cycloolefin resin (ZEONOR1600R manufactured by Japan ZEON Co., Ltd.) was dissolved in 75 parts by weight of xylene, cyclohexane, toluene mixed solvent (the weight mixing ratio was 1:1:1), and cast method to make a film, and then apply 100W / m to both sides of the film in the air 2 Corona discharge treatment is carried out according to the treatment intensity, and then as the first layer of primer, a polyester polyol compound (Seika Dyne (Seikadain) LB manufactured by Dainichi Seika Industry Co., Ltd.) is coated on one side of the film. ) and polyisocyanate (Seika Dyne 3500A manufactured by Dainichi Seika Industry Co., Ltd.) (weight ratio 1:11), and then dried. The thickness after drying should reach 0.2 μm. Then, as the second layer of primer, apply a 5% aqueous solution of polyvinyl alcohol with an average degree of polymerization of 1500 and a degree of saponification of 99% on this layer, and then make it dry. The thickness after drying should re...

Embodiment 2

[0084] PVA film (Kurali vinylon film VF-9X75R manufactured by Kuraray Co., Ltd., thickness 75 μm) was immersed in an aqueous solution composed of 5000 parts by weight of water, 35 parts by weight of iodine, and potassium iodide of 525 parts by weight for 5 minutes for it to absorb iodine. Next, the film was stretched 4.4 times in the longitudinal direction in a 4% by weight aqueous solution of boric acid at 45° C., and then dried under tension to obtain a polarizing film.

[0085] Next, a 5% aqueous solution of PVA with an average degree of polymerization of 1800 and a degree of saponification of 99% is used as a binder in an undried state, but the thickness after drying is required to be 1 μm.

[0086] Next, the obtained polarizing film was laminated with the pair of protective films obtained in Example 1 so that the thickness of the obtained laminated body after drying was 1 µm, by sandwiching between them an average poly Degree is 1800, saponification degree is the 5% aque...

Embodiment 3

[0088] After storing the rolled protective film obtained in Example 1 at normal temperature for one month, a polarizing plate was produced in the same manner as in Example 2. Table 2 shows the evaluation results of this polarizing plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com