Method for synthesizing new titanium-silicone metapore molecular sieve

A technology of mesoporous molecular sieve and synthesis method, which is applied in the field of synthesis of new titanium-silicon mesoporous molecular sieves, can solve problems such as poor structural order and application limitations, and avoid TiO2 precipitation and generation of TiO2 impurity phases. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

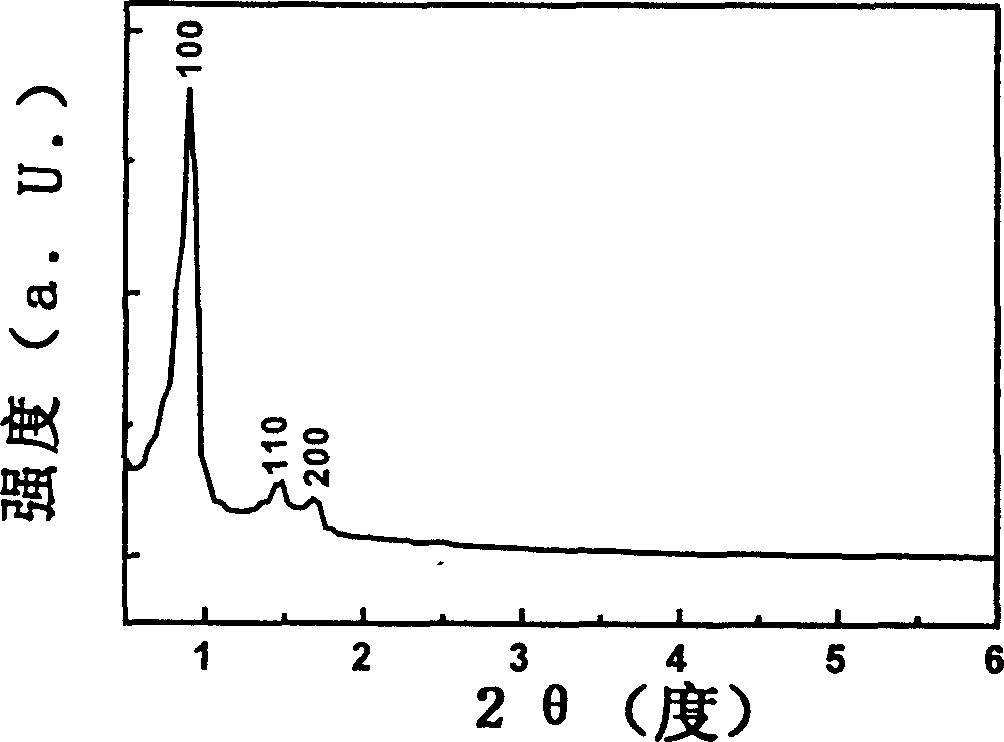

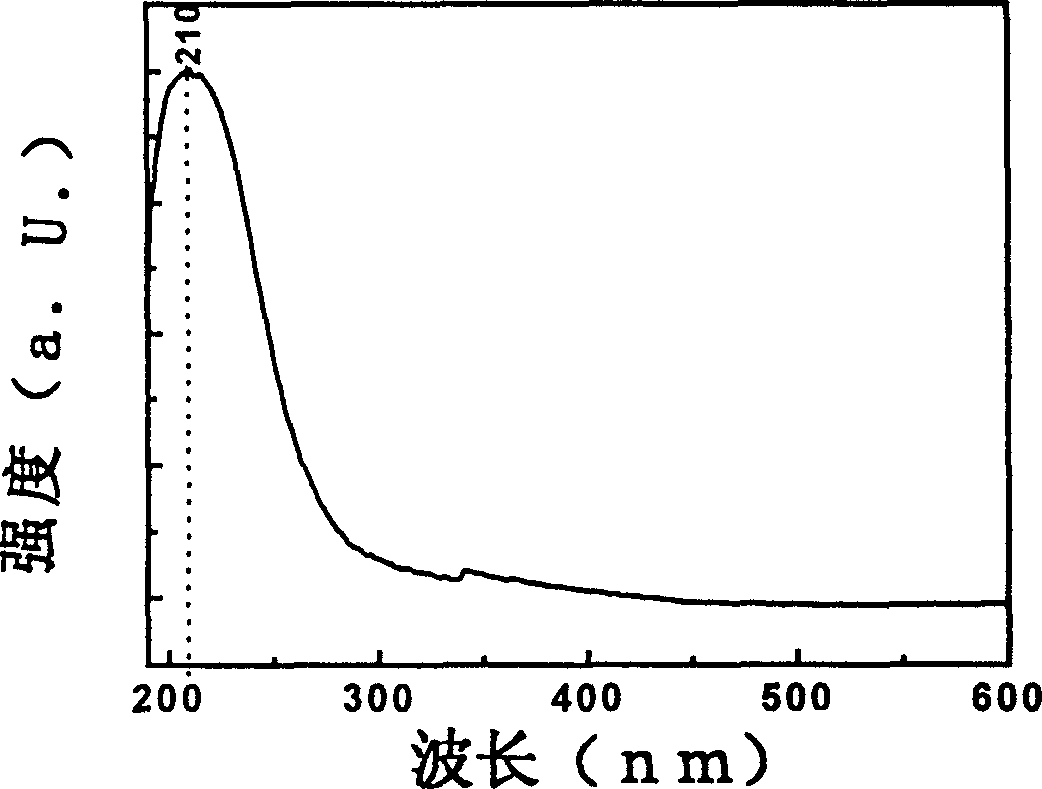

[0034] 2 g of P123 (EO 20 PO 70 EO 20 ) surfactant was dissolved in 75ml of HCl solution with pH 1.0, stirred at 35-45°C for 5 hours, then added with molar ratio SiO 2 / F - 35 NH 4 F, add 7 g of methyl orthosilicate and TiO under vigorous stirring 2 / SiO 2 The isopropyl titanium mixture with a molar ratio of 1% was continuously stirred at high speed for 15 hours, and then the resulting gel was transferred to an oven at 60° C. and kept at least 24 hours. The white crystalline solid product is separated from the mother liquor, washed with deionized water until neutral, and dried under an air atmosphere below 100°C for 10 hours, and finally sintered at 500°C for 10 hours to obtain Ti- with a titanium content of 1.0%. SBA-15 mesoporous molecular sieve material. Wherein the titanium content is 1.0% the sample 1# XRD crystallographic pattern is as follows figure 1 Shown, ultraviolet-visible absorption spectrum (UV-vis) see figure 2 As can be seen from the figure, the three...

example 2

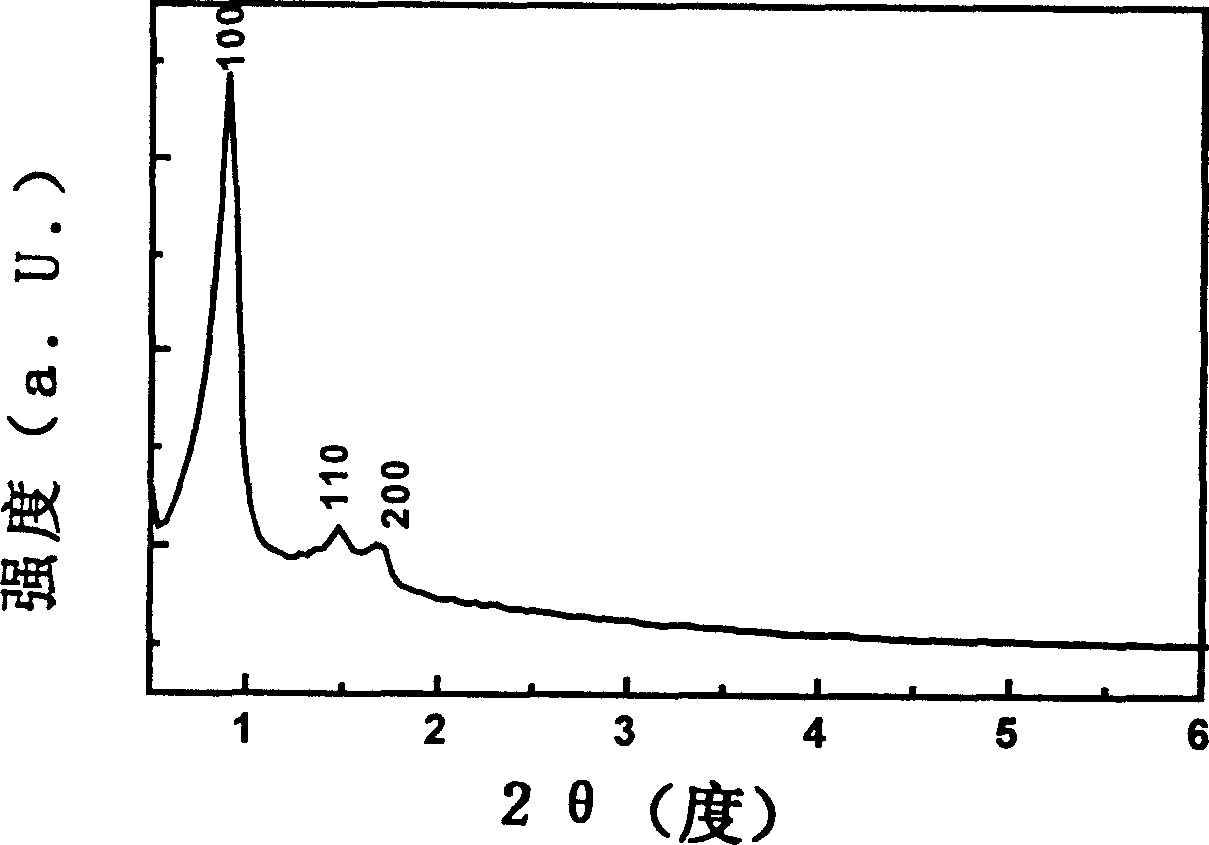

[0036] Change the HCl solution of pH 1.0 in Example 1 to the solution of pH 2.0, and other conditions and processes remain unchanged, and the titanium-containing-SBA-15 mesoporous molecular sieve material can also be obtained. Wherein the titanium content is 1.0% the sample 2# XRD crystalline pattern pattern such as image 3 Shown, UV-vis absorption spectrum see Figure 4 Although the sample still has three low-angle diffraction peaks, it shows that the obtained sample is a high-quality SBA-15 structure material, but in the UV-vis spectrum, it can be found that the tailing phenomenon of the absorption band of sample 2# at 210nm is very Seriously, this shows that not only some Ti 4+ into the framework of the sample, and there is a large amount of non-framework TiO 2 exist.

example 3

[0038] Change the HCl solution of pH 1.0 in Example 1 to the HCl solution of 1M concentration, and other conditions and processes remain unchanged, and Ti-SBA-15 mesoporous molecular sieve materials containing titanium can also be obtained. Wherein the titanium content is 1.0% the sample 3# XRD crystalline pattern pattern as image 3 shown by image 3It can be seen that the obtained material is a high-quality SBA-15 structure, and at the same time, from the UV-vis spectrum Figure 4 It can be seen that no non-framework titanium species were found in sample 3#, and most titanium should exist in the form of framework titanium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com