Organic film transistor

An organic thin film and organic film technology, applied in the field of organic TFT, can solve the problems of insufficient mobility of organic compounds and inability to achieve driving speed, etc., and achieve the effects of high-speed response, short channel length, and high carrier mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

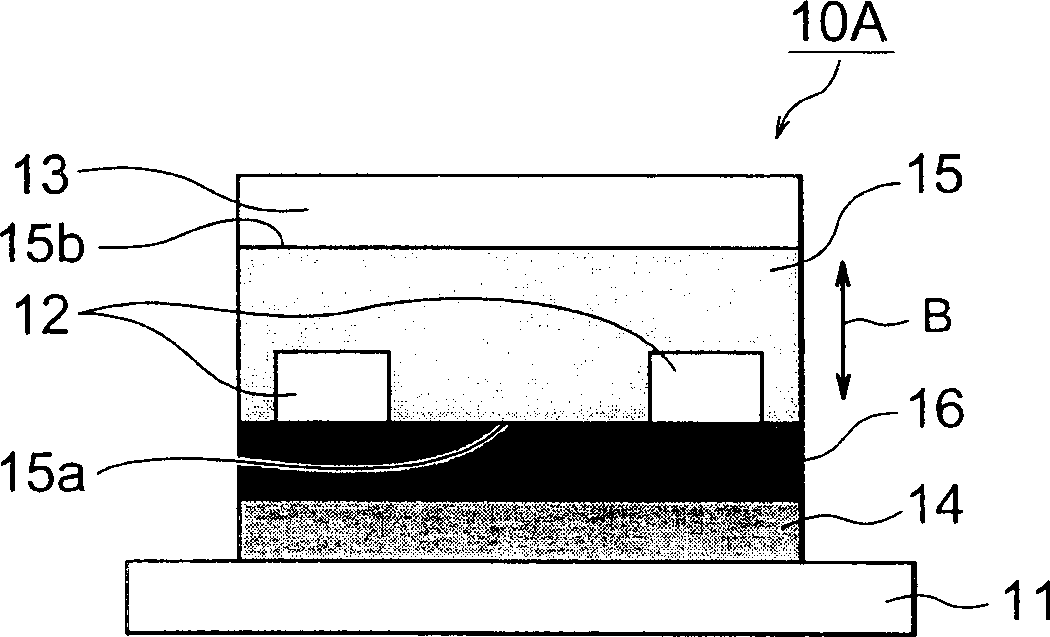

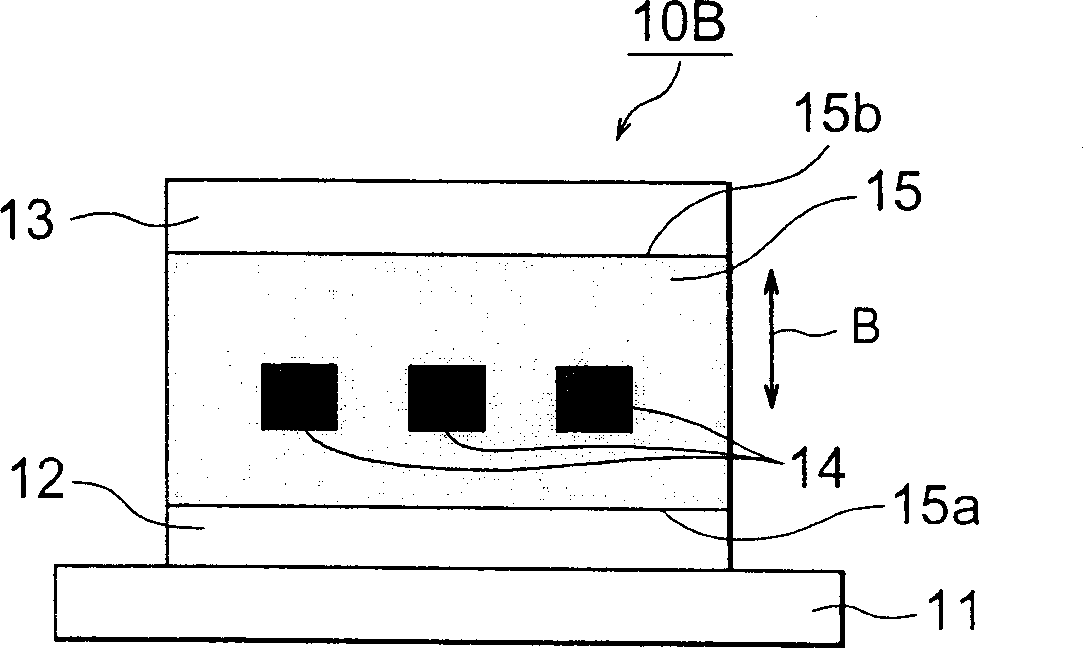

[0024] Such as figure 2 As shown, an organic TFT 10A having a FET (Field Effect Transistor) structure includes a laminated structure on a substrate 11 . The laminated structure includes a structure on a substrate 11 in which gate electrodes 14 and dielectric layers 16 are arranged in sequence, and strip-shaped source electrodes (first electrodes) 12 are installed on the dielectric layers 16 respectively. Further, an organic film (organic compound layer) 15 is formed on the surface of the source electrode 12 and the exposed surface of the dielectric layer 16 , and a drain electrode (second electrode) 13 is formed on the organic film 15 . The source electrode 12 is in contact with the side and bottom surfaces of the organic film 15 , and the drain electrode 13 is in contact with the top surface 15 b of the organic film 15 .

[0025] In the organic TFT 10A having the above structure, the organic film 15 forms a channel region, and the ON / OFF operation controls the flow of curre...

Embodiment 1

[0062] exist figure 2 The organic TFT 10A of the first embodiment shown in is manufactured as follows.

[0063] On the substrate 11, a gate electrode 14 was formed to a thickness of 100 nm by vacuum-depositing chromium. Then, SiO is formed on the gate electrode 14 by sputtering 2 film, thereby forming a dielectric layer 16 with a thickness of 300 nm. A magnesium-silver alloy is vacuum-deposited on the dielectric layer 16 through a metal mask to form a strip-shaped source electrode 12 with a thickness of 100 nm.

[0064] Then, compound (1') was vacuum-deposited on the dielectric layer 16 and the source electrode 12 to form an organic film 15 with a thickness of 300 nm. Next, a magnesium-silver alloy was vacuum-deposited on the organic film 15 to form the drain electrode 13 with a thickness of 200 nm, thereby fabricating the organic TFT 10A.

[0065] A rectangular pulse voltage with a frequency of 1k Hz and a maximum voltage of 8.5V was applied to the gate electrode 14 of t...

Embodiment 2

[0067] An organic TFT was fabricated according to the procedure of Example 1, except that compound (3') was used instead of compound (1'). The response rise time for measuring the conduction state between the source-drain electrodes of the organic TFT is less than 1 μs, which is similar to that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com