Method for preparing nano grain film biphobic coating by normal pressure medium barrier discharge polymerization

A technology of dielectric barrier discharge and nano particles, which is applied in coatings and devices for coating liquid on the surface, etc., can solve the problems of high cost, unfavorable large-scale production, and no research reports, etc., achieve low energy consumption, overcome the principle of fabric It has a great effect on performance and good hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Clean the cotton fabric sample and place it in the electrode discharge reaction zone of the dielectric (alumina) barrier discharge reactor. Argon and Monomer CF 4 The mixing ratio is 300:1, mixed to form a reaction gas, the flow rate of the reaction gas is 0.32SLM, the power is 11kw, and the discharge treatment is carried out at normal pressure and room temperature, and the treatment time is 1 minute. Table 1 and Table 2 compare the contact angle, fabric moisture permeability and hand comfort of the obtained atmospheric pressure plasma coating on the cotton fabric with the vacuum coating and Scotchgard commercial waterproof finishing agent.

[0036] Table 1. Comparison of fabric contact angle, fabric moisture permeability rate and moisture permeability index

[0037] Contact angle (degrees) Moisture permeability rate Coating type Moisture permeability index

[0038] Water Glycerin α-bromonaphthalene (g / min.cm 2 ) Atmospheric pressu...

Embodiment 3

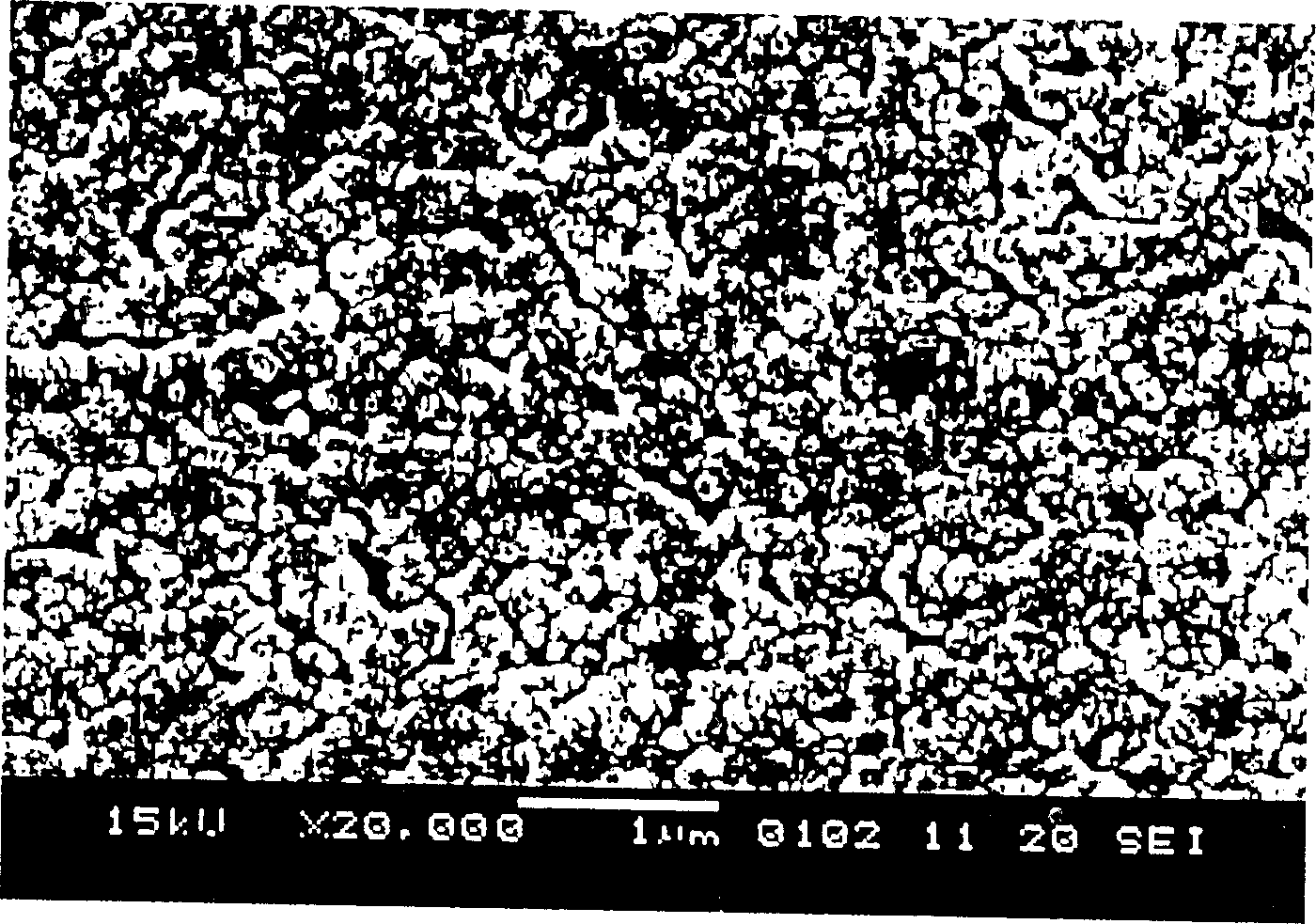

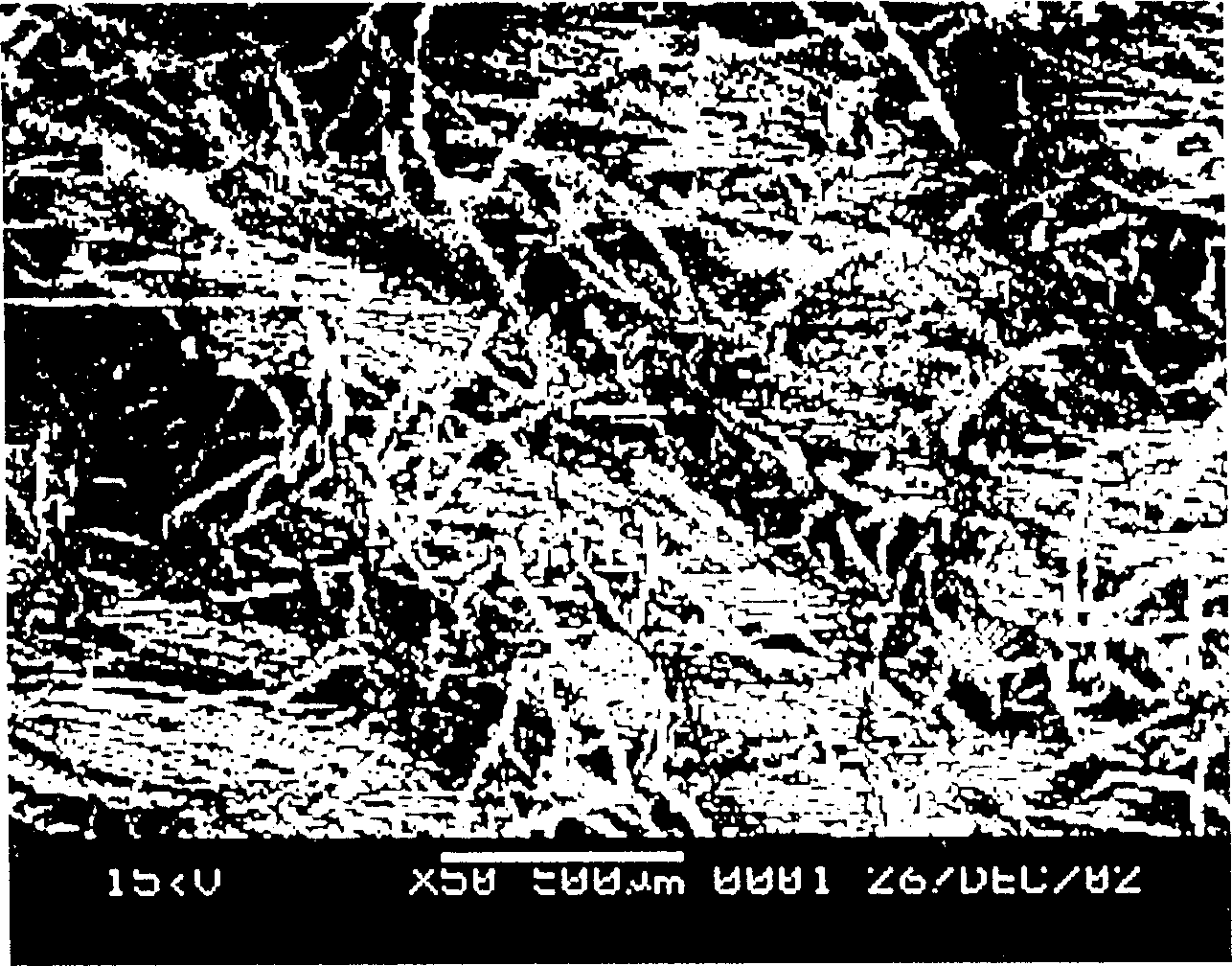

[0042] Clean the fabric and fiber samples, place them in the electrode discharge reaction zone of the dielectric (alumina) barrier discharge reactor, neon gas and monomer C 6 f 6 The mixing ratio is 500:1, the flow rate of the mixed reaction gas is 0.2SLM, the power is 10kw, and the discharge treatment is carried out at normal pressure and room temperature. The electron microscope observation picture of the fabric and fiber for 6 minutes is shown in image 3 with Figure 4 , showing that the coating is a nanoparticle stacked film with a porous structure, which provides a certain roughness to the surface and contributes to the improvement of hydrophobicity and oleophobicity.

Embodiment 4

[0044] The glass sheet and the cotton fabric sample are cleaned, placed in the electrode discharge reaction zone of the dielectric (quartz glass) barrier discharge reactor, helium and monomer C 8 f 18 The mixing ratio is 500:1, the flow rate of the mixed reaction gas is 0.8SLM, and the power is 10kw. The glass sheet and cotton fabric are discharged at normal pressure and room temperature. The treatment time is 30 seconds. For photos of standing water drops, see Figure 5 with Image 6 , the water drops can last until the natural complete volatilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com