Pressure increased diesel wet air-diesel homogeneous combustion system

A homogeneous combustion, diesel engine technology, applied in the direction of charging system, mechanical equipment, engine components, etc., can solve the problem of no improvement in particle emissions, and achieve the effect of easy control and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

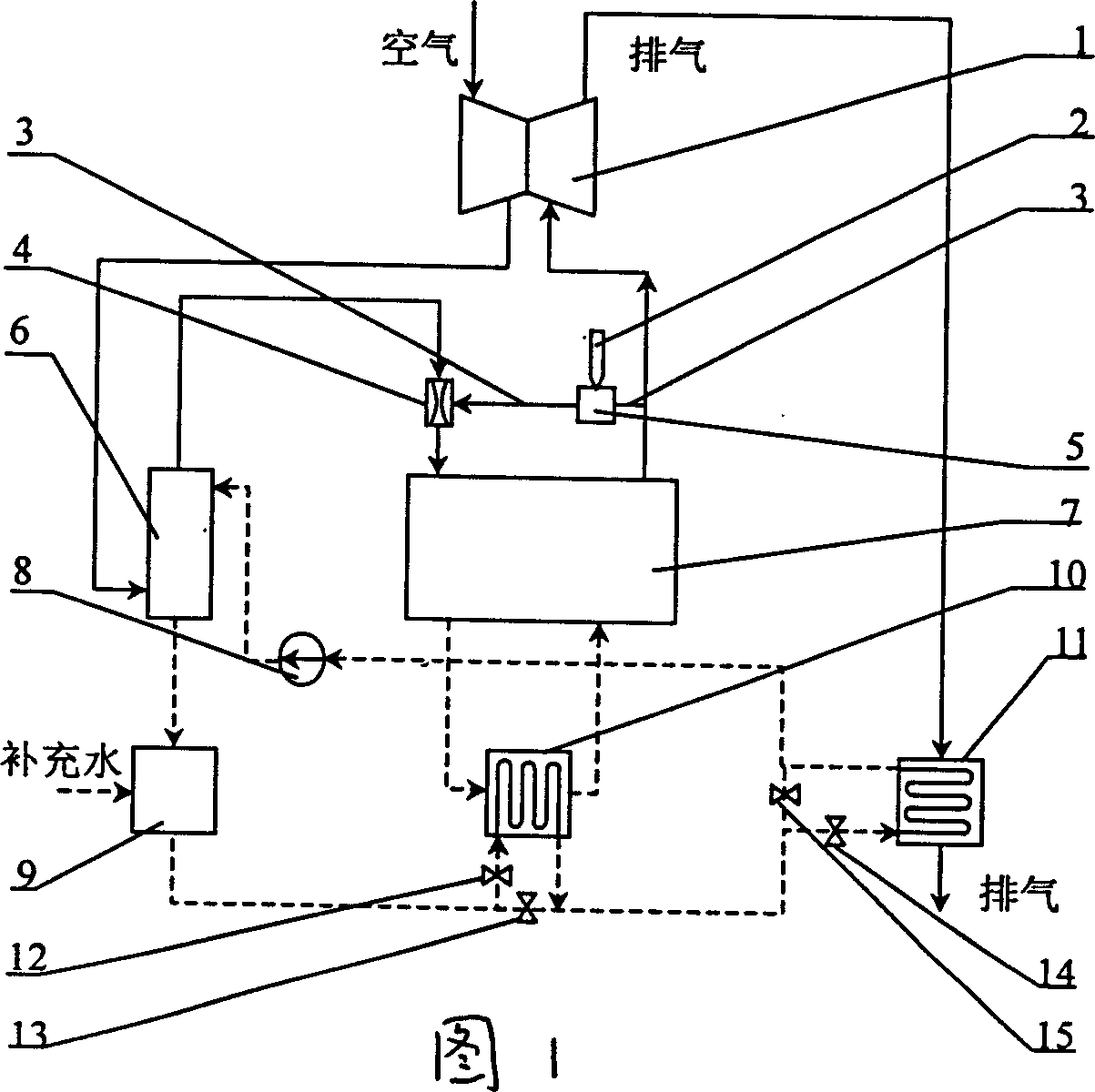

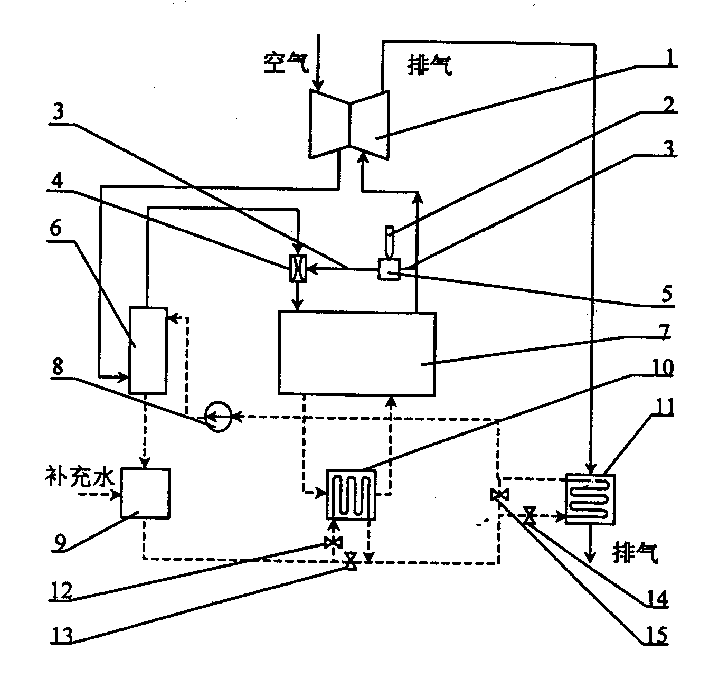

[0012] The specific implementation of the present invention will be further described below in conjunction with accompanying drawing:

[0013] As shown in Figure 1, the present invention mainly comprises: turbocharger 1, fuel injection nozzle 2, exhaust gas recirculation pipe 3, Venturi pipe 4, mixing chamber 5, humidifier 6, diesel engine 7, water pump 8, water tank 9 , Preheating heat exchanger 10, reheating heat exchanger 11, control valves 12-15 and connecting pipelines, etc. The inlet end of the turbocharger 1 is connected to the atmosphere, the outlet end of the turbocharger is connected to the air inlet at the lower end of the humidifier 6, the humid air outlet at the upper end of the humidifier 6 is connected to the inlet of the Venturi tube 4, and the outlet of the Venturi tube 4 It is connected with the intake pipe of the diesel engine 7; the inlet of the exhaust gas recirculation pipe 3 communicates with the exhaust pipe of the diesel engine 7, and a diesel / exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com