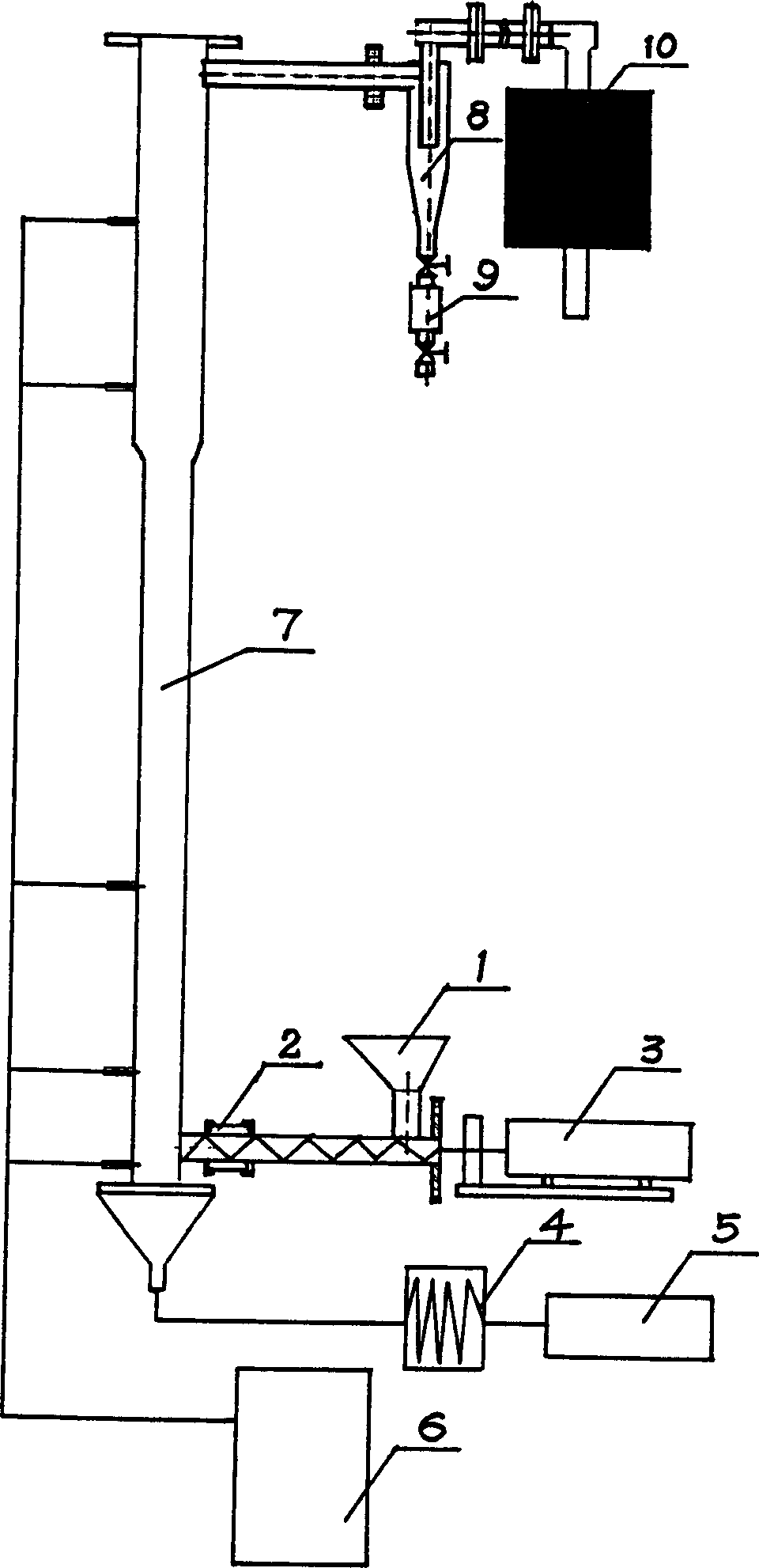

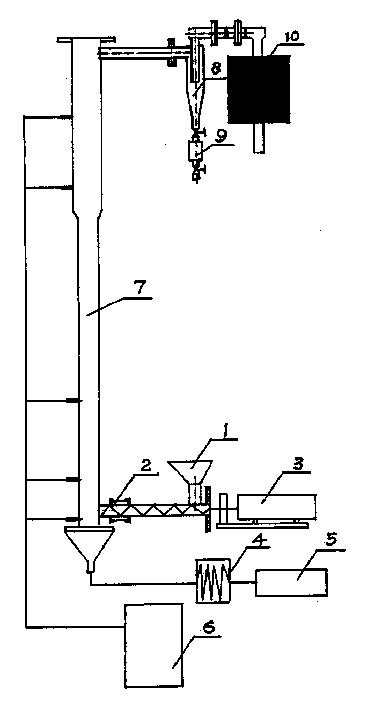

Method and apparatus for producing hydrogen by catalytic cracking of biologic matter

A catalytic cracking and biomass technology, applied in the field of biomass catalytic cracking to produce hydrogen, to achieve wide adaptability, improve conversion rate and energy utilization efficiency, and reduce tar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] After the air is boosted by the blower 5, the air is heated to above 300°C by the air preheater 4 and passed into the lower part of the fluidized bed reactor 7, after flowing through the distribution plate, it enters the feed bin 1 and is fed by the screw feeder 3 The burning of pine wood powder produces a high temperature of more than 700 ℃. The temperature between the fluidized bed reactor 7 and the screw feeder 3 is lowered by a cooling system 2 passing through cooling water to ensure the smooth flow of biomass feed. Simultaneously, the superheated water vapor produced by steam generator 6 is introduced from different regions of fluidized bed reactor 7, and most of the pine wood powder is fluidized under high-temperature environment, and is reacted on iron-based catalyst, alkali metal catalyst and nickel-based catalyst. Catalytic gasification, water-gas shift, and tar cracking reactions occur in different areas of the fluidized bed reactor 7 under the action of 0.5 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com