Electrode assembly

A technology of electrodes and electric fields, applied in the field of substrate devices, can solve the problems of high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Detailed description of the preferred embodiment

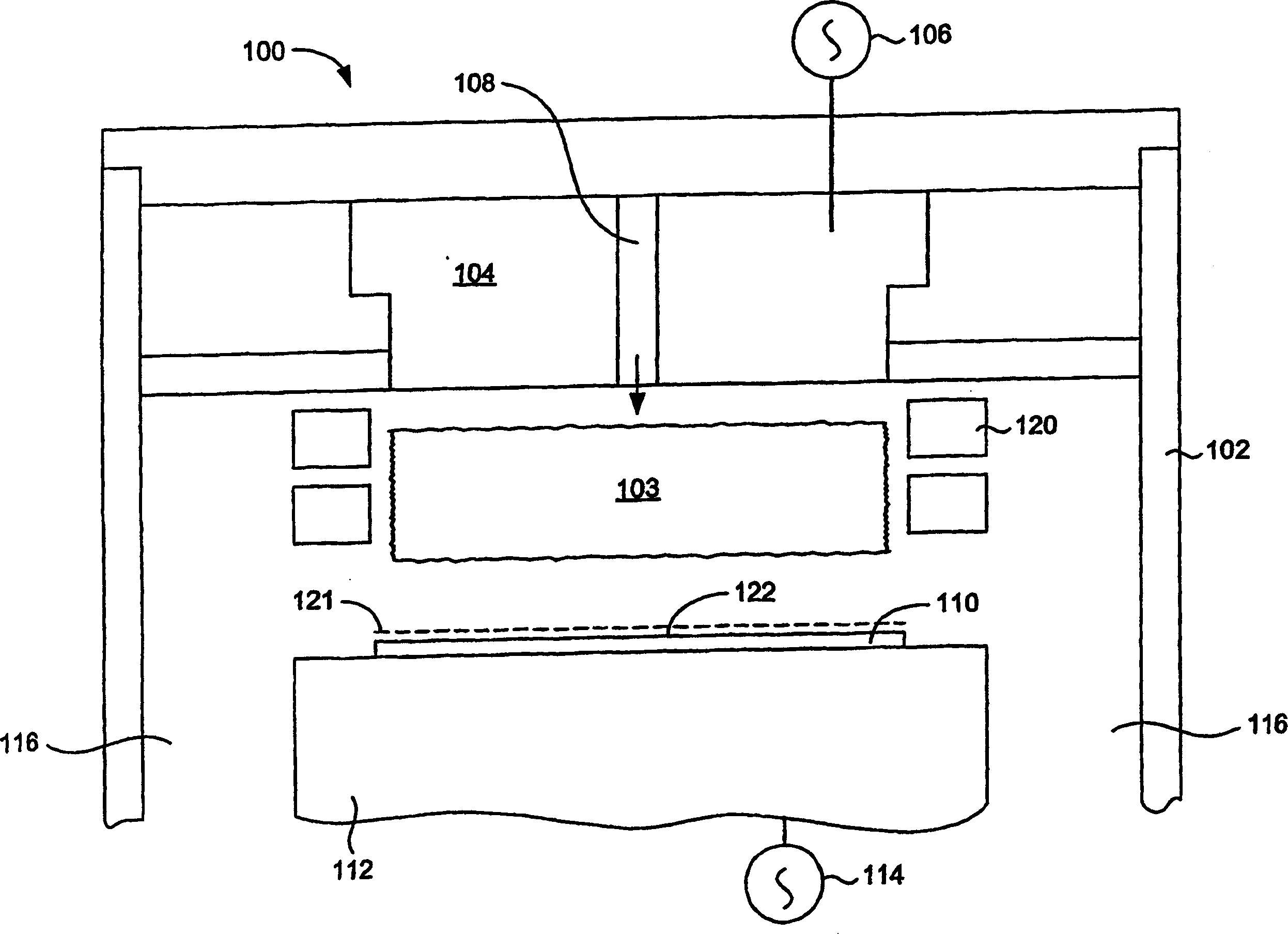

[0016] During substrate processing, one of the most important parameters that process engineers strive to improve is process uniformity. As the term is used herein, process uniformity refers to the uniformity of the overall process across the surface of the substrate. For example, if processing is to be highly uniform, it is desirable that the processing rates at different points on the substrate tend to be substantially equal. In this case, it is less likely that one region of the substrate will be unduly overprocessed while other regions remain underprocessed.

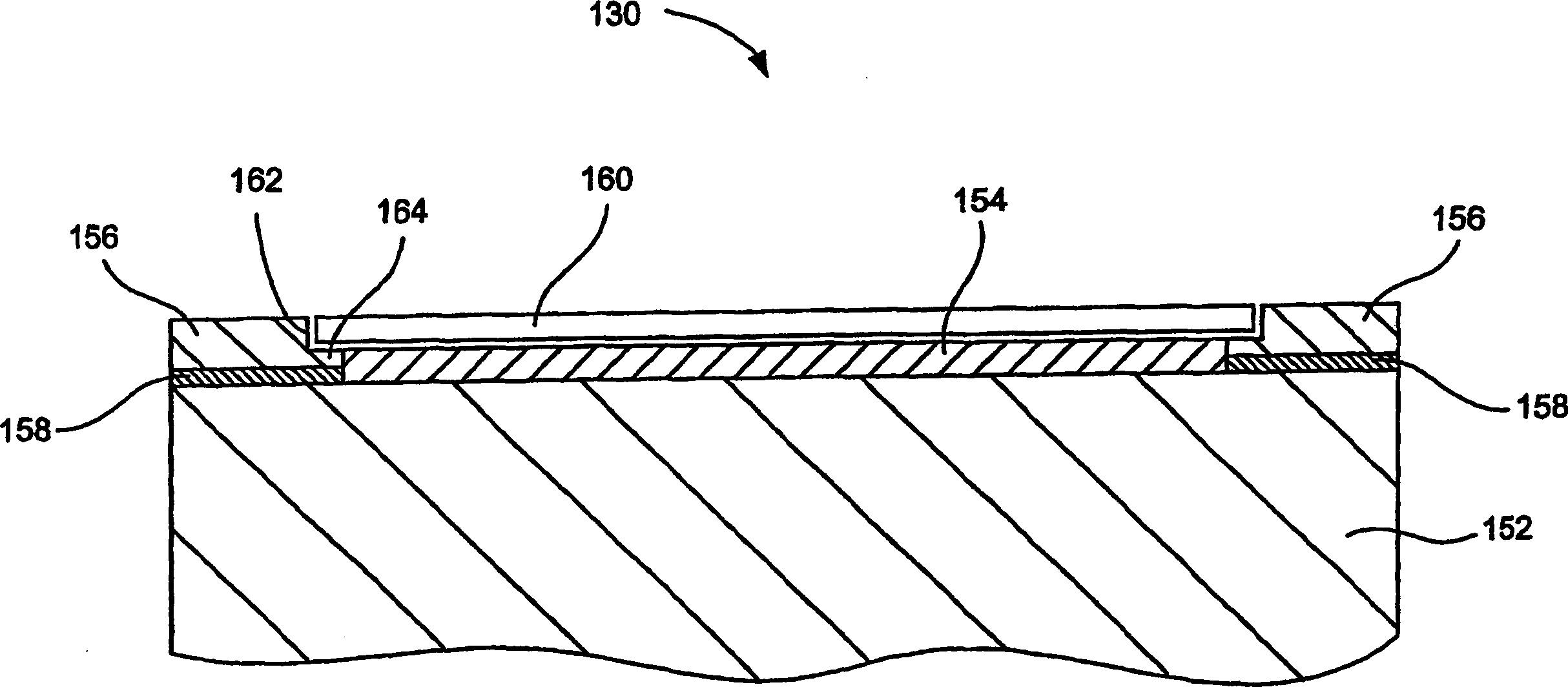

[0017] The present invention therefore relates to improved methods and apparatus for processing substrates. More specifically, the present invention relates to a substrate holder capable of producing a high degree of process uniformity across the surface of the substrate. The substrate support is configured to reduce electrical and thermal discontinuities t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com