Method for cleaning plasma processing device

A processing device and plasma technology, applied in cleaning methods and appliances, chemical instruments and methods, metal material coating technology, etc., can solve the problem that deposits cannot be completely removed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation plan

[0026] Referring to the accompanying drawings, embodiments of the present invention will be explained below:

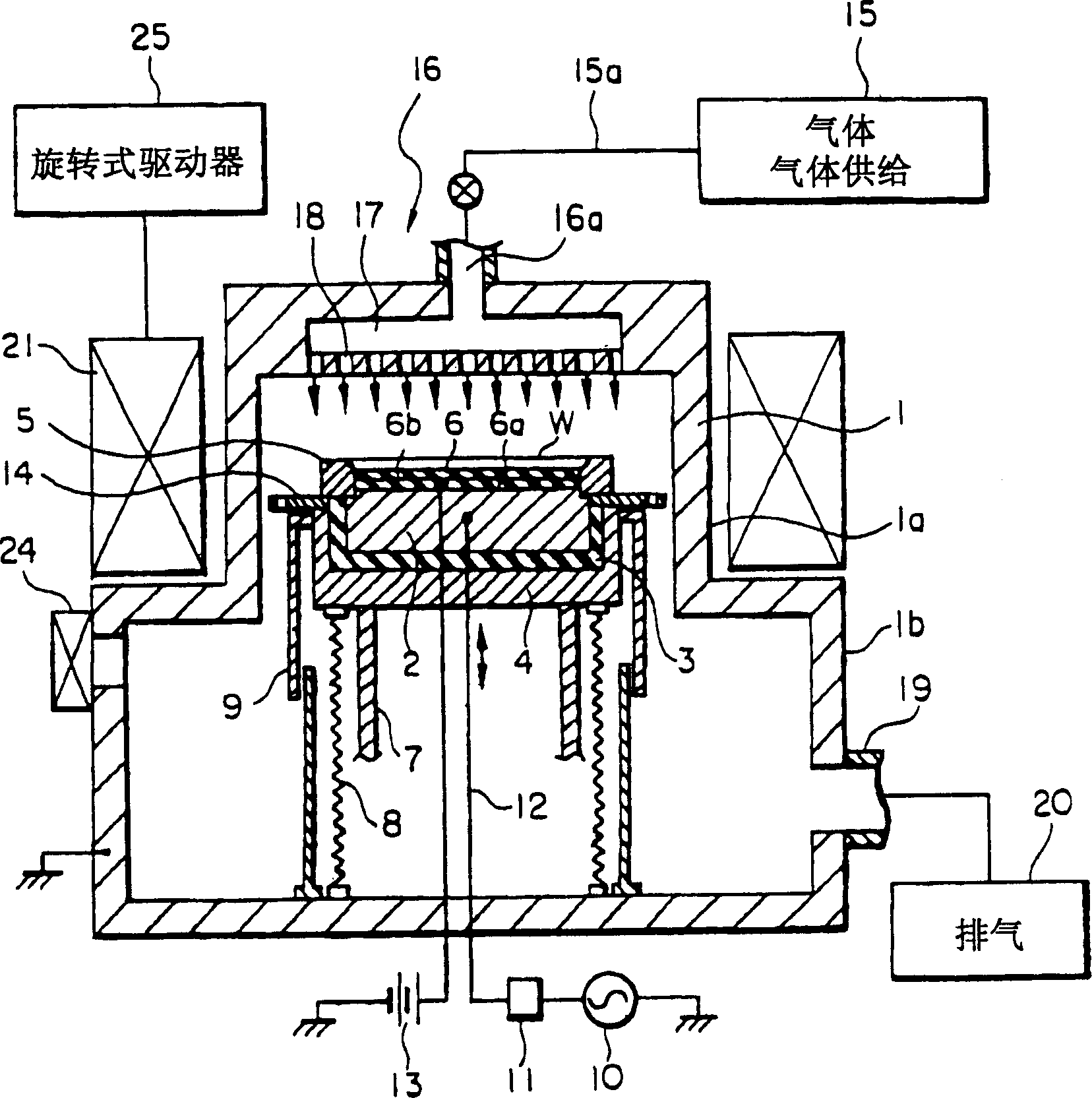

[0027] figure 2 is a schematic structural view of the etching device, wherein 1 indicates an aluminum cylindrical vacuum chamber, and its inside is airtight, which is a plasma etching chamber.

[0028] The vacuum chamber 1 has a trapezoidal cylindrical shape, has an upper portion 1a with a smaller diameter, and a lower portion 1b with a larger diameter, and is electrically grounded. Further, here, a support table (receiver) 2 for supporting a semiconductor wafer W as a substrate to be processed is provided inside the vacuum chamber 1, with its surface to be processed positioned upward and almost horizontally.

[0029] The support table 2 is made of, for example, aluminum, and is supported by a support base 4 via an insulating plate 3 such as a ceramic plate. Further, here a focus ring 5 made of conductive or insulating materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com