Dry-process method for producing bentonite

A production method and technology of bentonite, applied in the field of deep processing of bentonite materials, can solve problems such as difficulty in large-scale and continuous production, large investment in equipment, complicated process, etc., and achieve the effect of easy large-scale production, low investment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

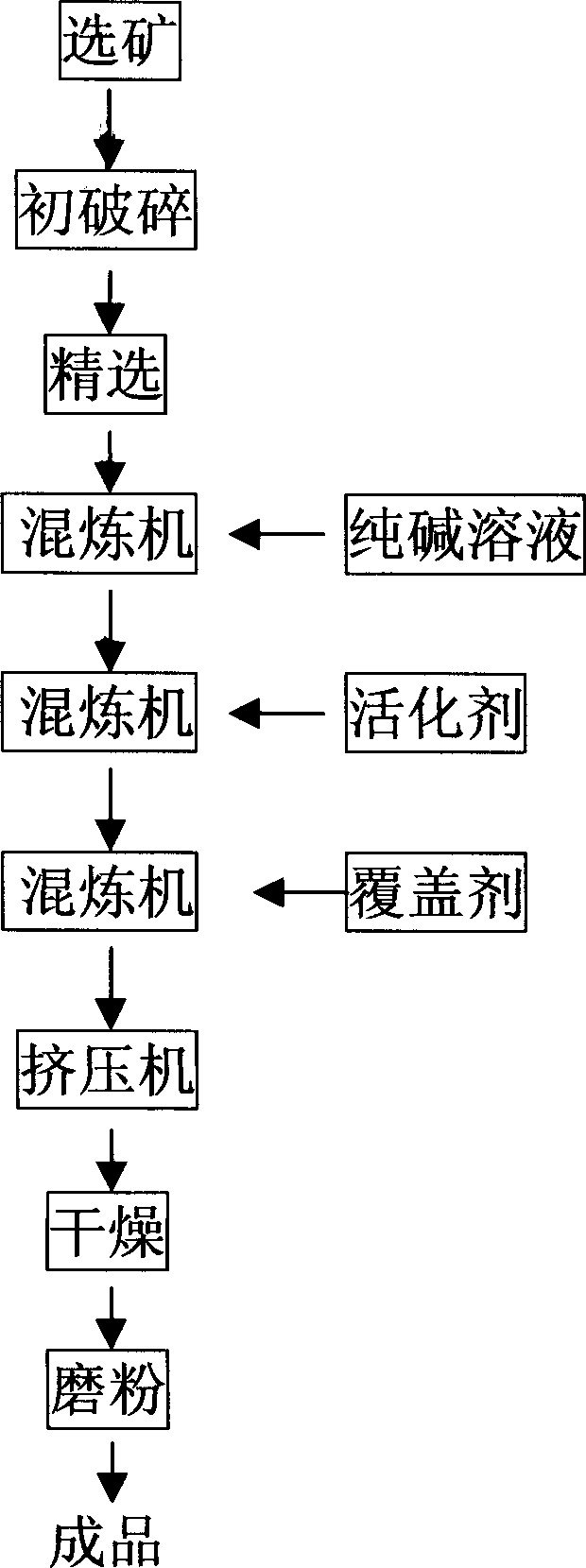

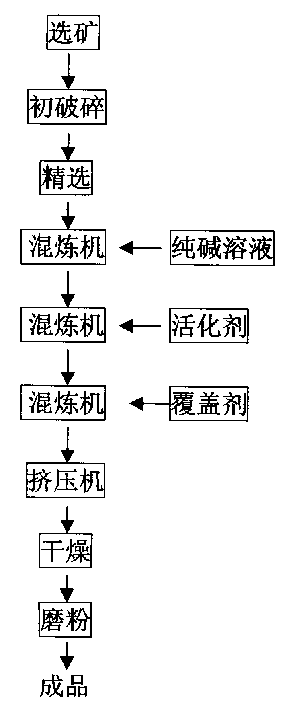

Image

Examples

Embodiment Construction

[0007] 1. Mineral dressing: Use natural calcium-based bentonite with good purity, its montmorillonite content is greater than 85%, whiteness is greater than 80%, cation exchange capacity is greater than 85mmol / 100g, and sandstone is less.

[0008] 2. Primary crushing: primary crushing of bentonite to less than 4mm.

[0009] 3. Selection: add twice as much water as bentonite, stir, and discard impurities such as sand and stone at the bottom.

[0010] 4. Adding soda ash solution: Add the selected bentonite into the kneader, and add 2-3% soda ash. The soda ash powder must meet the GB210-63 standard. Heating to 60°C, stirring and mixing, so that the calcium-based bentonite is modified into sodium-based bentonite.

[0011] 5. Add activator: Add 2-3% activator in the mixer, stir and mix. The purpose of adding activator is to facilitate the adsorption of covering agent on the surface of montmorillonite mineral.

[0012] 6. Adding covering agent quaternary ammonium salt: for the ben...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com