Composite thin film and preparing method thereof

A technology of composite film and film layer, applied in separation methods, chemical instruments and methods, membranes, etc., can solve problems such as cracks, and achieve the effect of high hydrogen permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

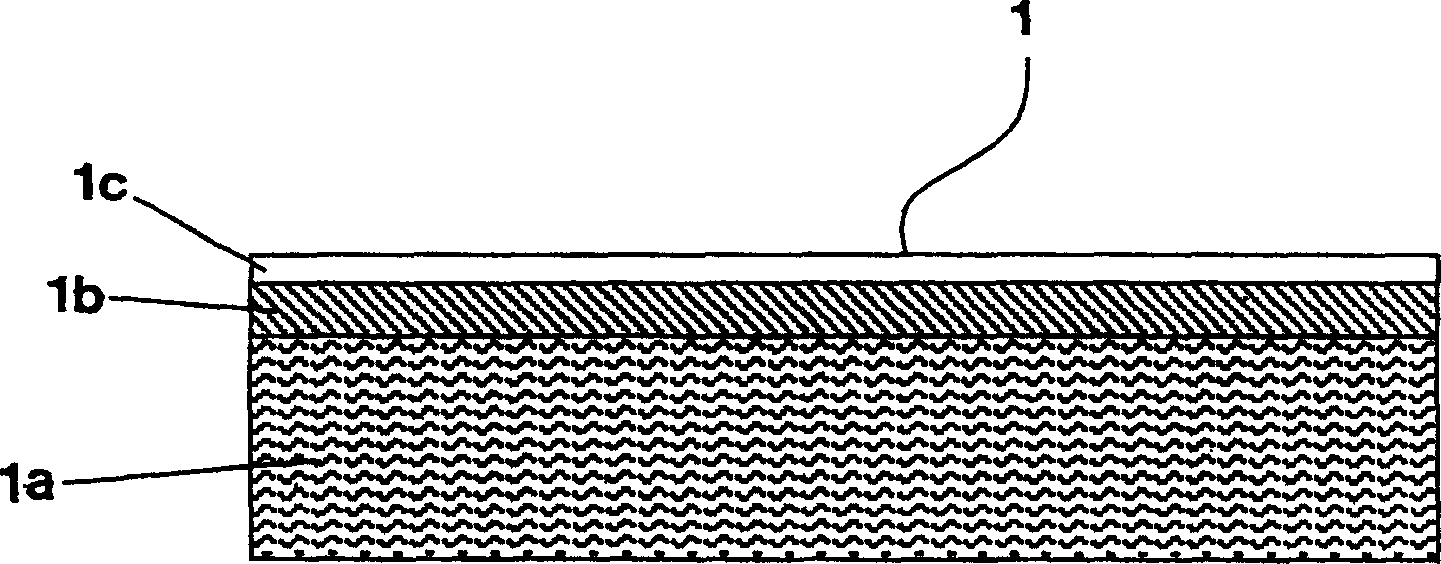

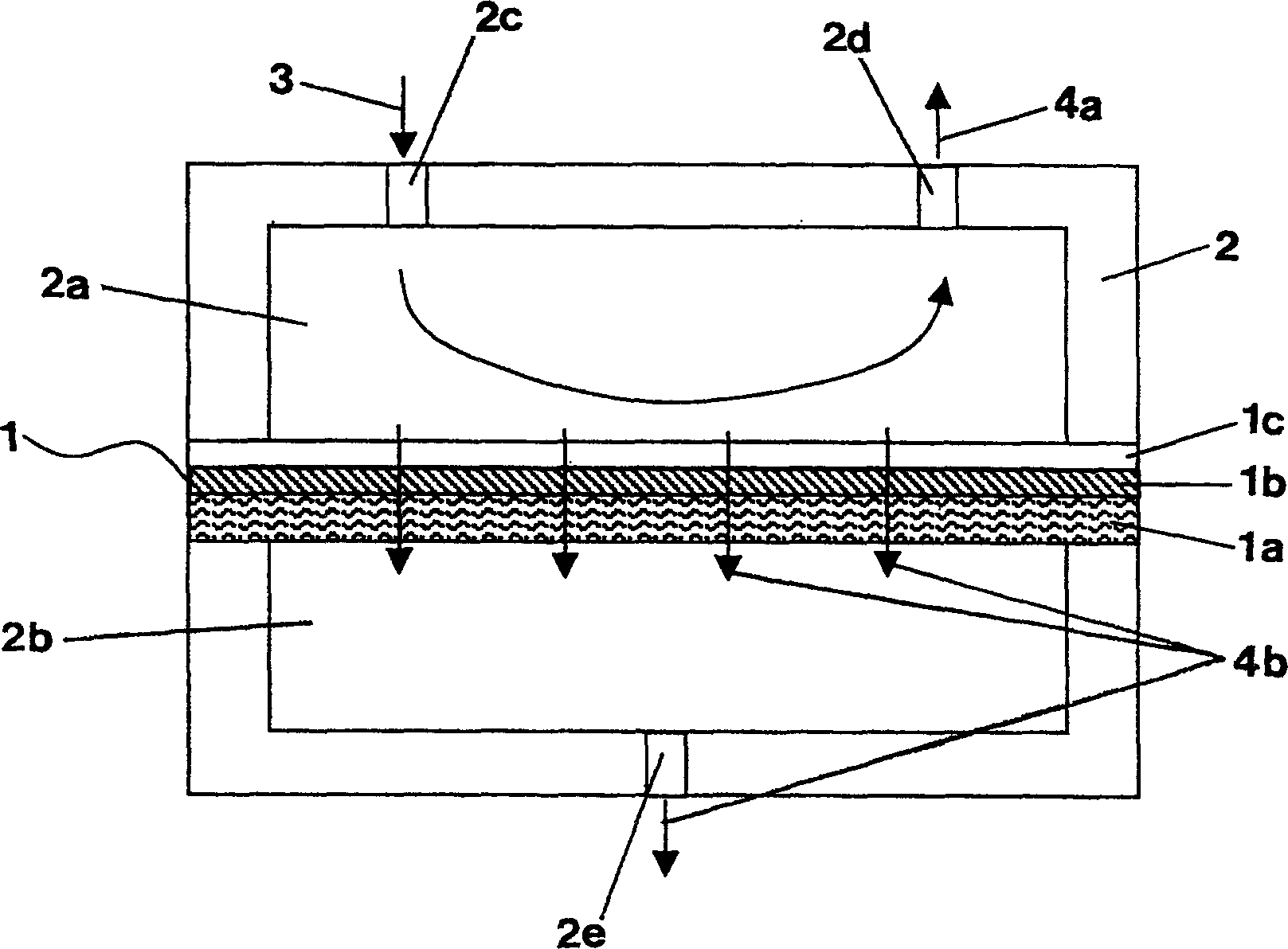

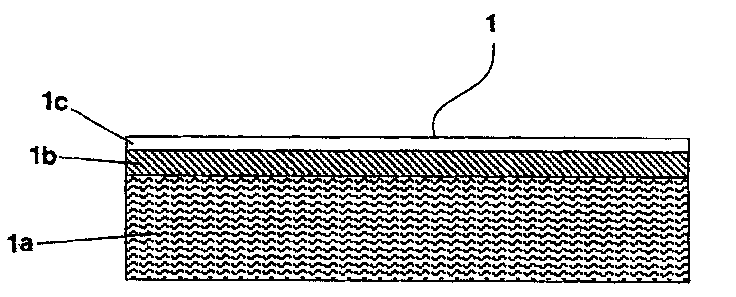

[0045] To prepare a composite film 1, an open-pored substrate 1a made of stainless steel with a thickness of 0.3 mm was cleaned, and a suspension containing nickel powder with a particle size of less than 1 μm was applied to one side thereof to fill the large pores and serve to eliminate surface inhomogeneities of the substrate 1a. The nickel powder is sintered together with the substrate 1a at 600° C. for about 1 hour to make it firmly bonded. The thus treated, cooled substrate 1a is then cleaned in an ultrasonic bath to remove loose nickel particles. Next, a diffusion barrier layer 1b made of TiN was formed on the treated surface of the substrate to a thickness of 2 m by cathode sputtering. The diffusion barrier layer 1b, which consists of only one single layer, is then directly electroplated to form a 4 μm thick palladium film on the electronically conductive surface facing away from the substrate 1a Layer 1c. The electrodeposition of palladium is carried out from an alk...

example 2

[0049]To prepare a composite film 1, as described in Example 1, an open-pored substrate 1a made of stainless steel with a thickness of 0.3 mm was cleaned and a suspension containing nickel powder with a particle size of less than 1 μm was applied to it. Its side is used to fill large pores and to eliminate surface inhomogeneities of the substrate 1a. The nickel powder is sintered together with the substrate 1a at 600° C. for about 1 hour to make it firmly bonded. The thus treated, cooled substrate 1a is then cleaned in an ultrasonic bath to remove loose nickel particles. Next, a diffusion barrier layer 1b made of TiN was formed on the treated surface of the substrate to a thickness of 2 m by cathode sputtering. The diffusion barrier layer 1b, which consists of only one single layer. Next, on the conductive surface facing away from the substrate 1a, it is covered by a dipping method with a palladium seed (which does not form a dense layer but exists as islands) . Next, elec...

example 3

[0051] To prepare a composite film 1, a perforated substrate 1a made of stainless steel with a thickness of 0.25 mm was cleaned. An alumina sol (for example, Nyacol AL20 from PQ Corporation) is applied to one side of the substrate 1a thereof to form a diffusion barrier 1b consisting of two monolayers to fill large pores and used to eliminate the unevenness of the surface of the substrate 1a. The substrate 1a was dried and heated at 650°C for about 2 hours to form a scratch-resistant aluminum oxide layer as the first monolayer of the diffusion barrier layer 1b. To obtain said diffusion barrier 1b, a second monolayer of TiN is subsequently applied by means of cathode sputtering onto the first monolayer of aluminum oxide on the side facing away from said substrate 1a. The conductive surface or second monolayer of the diffusion barrier layer 1b facing away from the substrate 1a is then subjected to direct electroplating to form a palladium thin film layer with a thickness of 5.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com