Organic positive temp. coefficient semistor

A technology of positive temperature coefficient and thermistor, which is applied to the manufacture of resistors, resistors, and resistors with positive temperature coefficients, which can solve the problem of reduced resistance value and inability to obtain sufficient characteristics and rate of change of overcurrent and overheat protection elements. Difficulties and other problems, to achieve the effect of large resistance change rate, high reliability, and increased bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

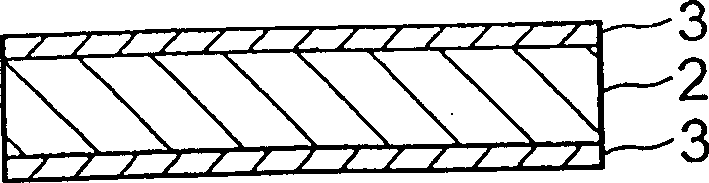

Method used

Image

Examples

Embodiment Embodiment 1

[0079] Linear low-density polyethylene (manufactured by Mitsui Chemicals, Inc., trade name Eboriyu-sp2520, MFR: 1.7 g / 10 min, melting point: 121°C) synthesized in the gas phase using a metallocene catalyst was prepared as a high molecular weight organic compound, paraffin (Baker Petrolite, trade name Poly Wax655, melting point 99°C) as a low molecular weight organic compound, filamentous nickel powder (manufactured by INCO, trade name 210 type nickel powder, average particle size 0.5-1.0 μm, bulk density about 0.8 g / cm 3 , specific surface area 1.5 ~ 2.5m 2 / g) as metal powder, and carbon black (manufactured by Mitsubishi Chemical Corporation, trade name MA100, average particle diameter about 22 nm) as non-metal powder.

[0080] First, according to the method described in the above-mentioned JP-A-11-242812, the alkoxysilane solution and the metal particles are thoroughly mixed, then the surface of the metal particles is covered with the non-metal powder by adding the non-metal...

Embodiment 2

[0092] Except that the amount of non-metallic powder is 0.5% by mass of metal powder, the mixing ratio is 49% by volume of high-molecular organic compound, 6% by volume of low-molecular organic compound, and 45% by volume of metal powder covered with non-metallic powder. In the same manner as Example 1, a thermistor element was fabricated. Compared with the element of Example 1, this thermistor element has a larger content of metal powder and a smaller amount of non-metal powder relative to the amount of metal powder. About this element, the characteristic was measured similarly to Example 1.

[0093] As a result, the initial room temperature resistance was 7.0×10 -3 Ω (resistivity 5.7×10 -2 Ωcm), the resistance increases rapidly near 90°C, and the resistance change rate is about 11 digits. It is confirmed that a low room temperature resistance and a large resistance change rate can be obtained. In addition, for the difference in the initial room temperature resistance valu...

Embodiment 3

[0097] Except that the amount of non-metallic powder is 1.0% by mass of metal powder, the mixing ratio is 49% by volume of high-molecular organic compound, 6% by volume of low-molecular organic compound, and 45% by volume of metal powder covered with non-metallic powder. In the same manner as Example 1, a thermistor element was fabricated. Compared with the element of Example 1, this thermistor element has a larger content of metal powder and a smaller amount of non-metal powder relative to the amount of metal powder. About this element, the characteristic was measured similarly to Example 1.

[0098] As a result, the initial room temperature resistance was 8.0×10 -3 Ω (resistivity 6.5×10 -3 Ωcm), the resistance increases rapidly near 90°C, and the resistance change rate is about 11 digits. It is confirmed that a low room temperature resistance and a large resistance change rate can be obtained. In addition, for the difference in the initial room temperature resistance valu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| apparent density | aaaaa | aaaaa |

| apparent density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com