Process for preparing magnesium carbonate whisker

A technology of magnesium carbonate whiskers and magnesium bicarbonate, which is applied in directions such as magnesium carbonate, can solve the problems of low purity, excessively large specific surface area of basic magnesium carbonate, poor mechanical properties of secondary agglomerated particles, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Calcinate 1000g of magnesite at 800°C for 2 hours, digest it with 20kg of tap water to form a slurry of magnesium hydroxide, cool it down to 40°C, pass carbon dioxide gas into it for carbonization reaction, and filter the slurry to obtain carbonic acid after reacting for 4 hours. Aqueous solution of magnesium hydrogen. Put 1000ml of the obtained magnesium bicarbonate aqueous solution into a beaker, add 1g of the additive sodium dihydrogen phosphate, and stir at a speed of 5rpm. After the additive is completely dissolved, heat the beaker to 65°C and increase the stirring speed to 120rpm. After 30 minutes of reaction, The resulting slurry was filtered and washed five times with 300 ml of deionized water. The filter cake obtained after washing and filtering was dried at 110° C. for 2 hours to obtain whiskers of magnesium carbonate.

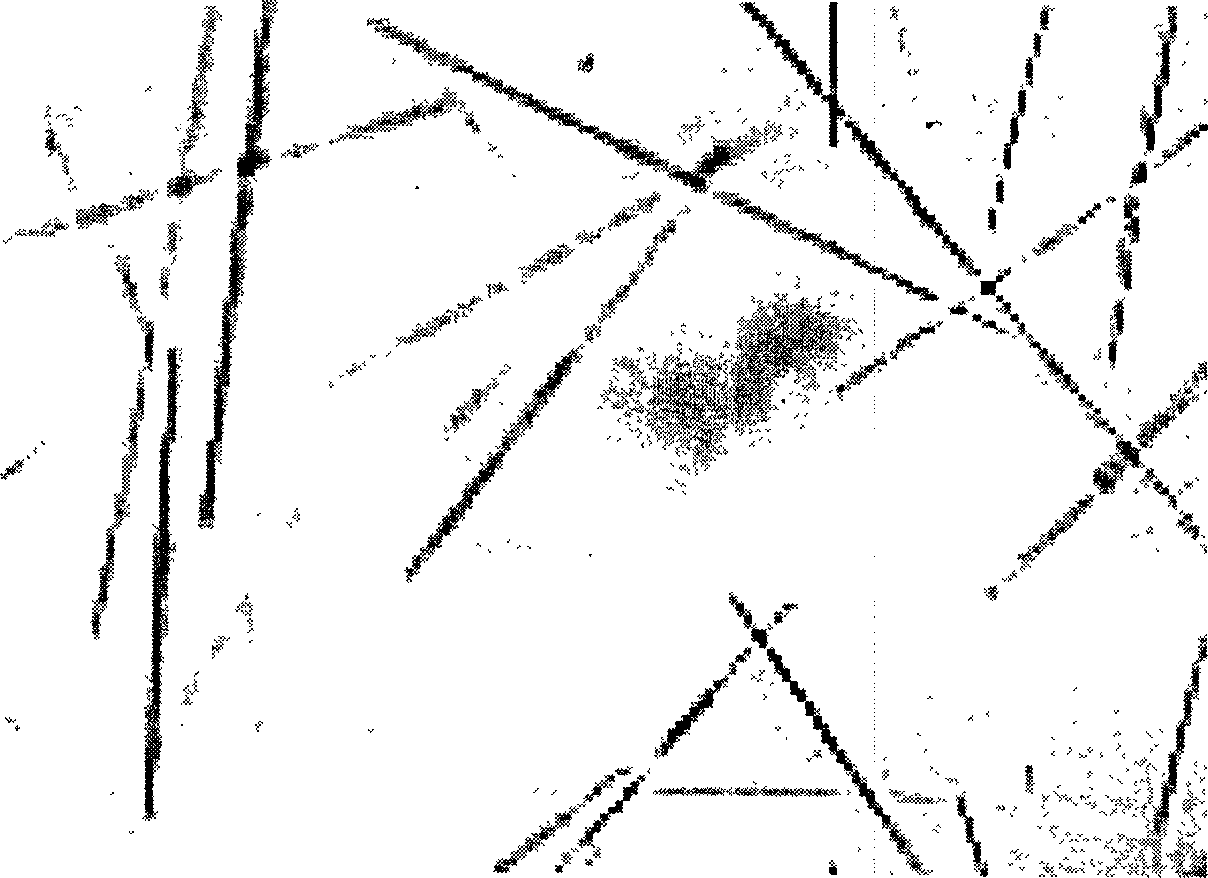

[0028] The whisker of magnesium carbonate obtained by the present embodiment is: have molecular formula: MgCO 3 ·3H 2 O, with a diameter o...

Embodiment 2

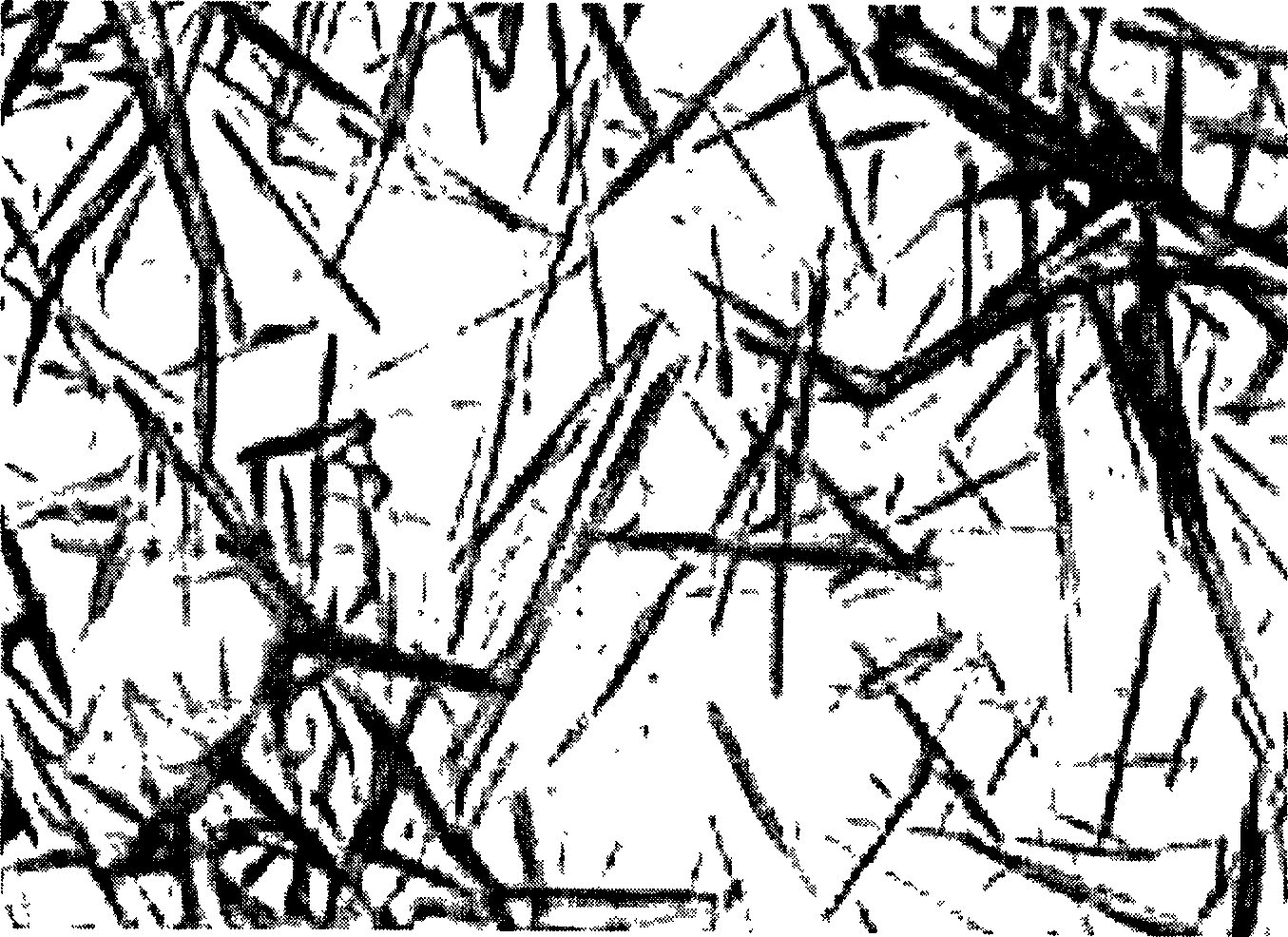

[0030] The method for preparing the magnesium bicarbonate solution is the same as in Example 1. Put 1000ml of the magnesium bicarbonate aqueous solution into a beaker, add 2g of the additive ammonium dihydrogen phosphate, and stir at a speed of 5rpm. After the additive is completely dissolved, heat the beaker to 50°C and increase the stirring. The speed was increased to 120 rpm, and after reacting for 40 minutes, the obtained slurry was filtered and washed with deionized water 5 times, 300 ml each time. The filter cake obtained after washing and filtering was dried at 110° C. for 2 hours to obtain whiskers of magnesium carbonate. The whisker of magnesium carbonate obtained by the present embodiment is: have molecular formula: MgCO 3 ·5H 2 O, with a diameter of 0.1-0.5 μm and a whisker length of 20-100 μm.

Embodiment 3

[0032] Take 80 g of chemically pure ammonium bicarbonate and 120 g of magnesium sulfate heptahydrate, heat them with 1000 ml of water respectively and mix them to obtain a mixed solution of magnesium bicarbonate and ammonium sulfate. Take 1000ml of this magnesium bicarbonate aqueous solution into a beaker, add 1g of sodium dodecylbenzenesulfonate, and stir at a speed of 5rpm. After the additive is completely dissolved, heat the beaker to 70°C, increase the stirring speed to 100rpm, and react for 20 minutes Afterwards, the obtained slurry was filtered and washed 5 times with deionized water, 300 ml each time. The filter cake obtained after washing and filtering was dried at 110° C. for 2 hours to obtain whiskers of magnesium carbonate. The whisker of magnesium carbonate obtained by the present embodiment is: have molecular formula: MgCO 3 ·3H 2 O, with a diameter of 0.5-1 μm and a whisker length of 60-200 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Whisker length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com