Semiconductor integrated circuit

An integrated circuit and semiconductor technology, applied in the field of semiconductor integrated circuits, can solve problems such as difficult and reliable laser fusing, and achieve the effects of easy laser fusing, low resistance, and easy laser fusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

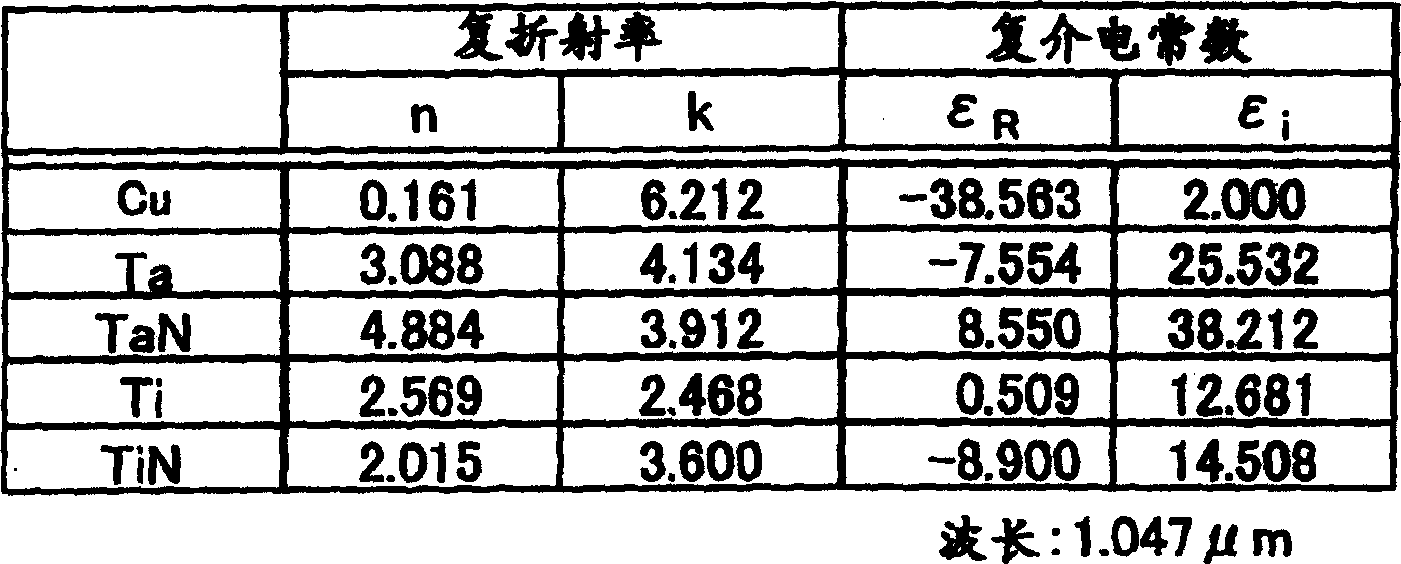

[0056] Since the reflectivity of copper to light in the infrared region is as high as 98% or more (the reflectivity of aluminum in this wavelength region is about 97%), a light absorbing member that effectively absorbs laser light is provided in the present invention. In the embodiment of the present invention, the copper fuse is laser blown using a laser in the infrared region, but the method of the present invention can also be applied to fuses such as aluminum or tungsten.

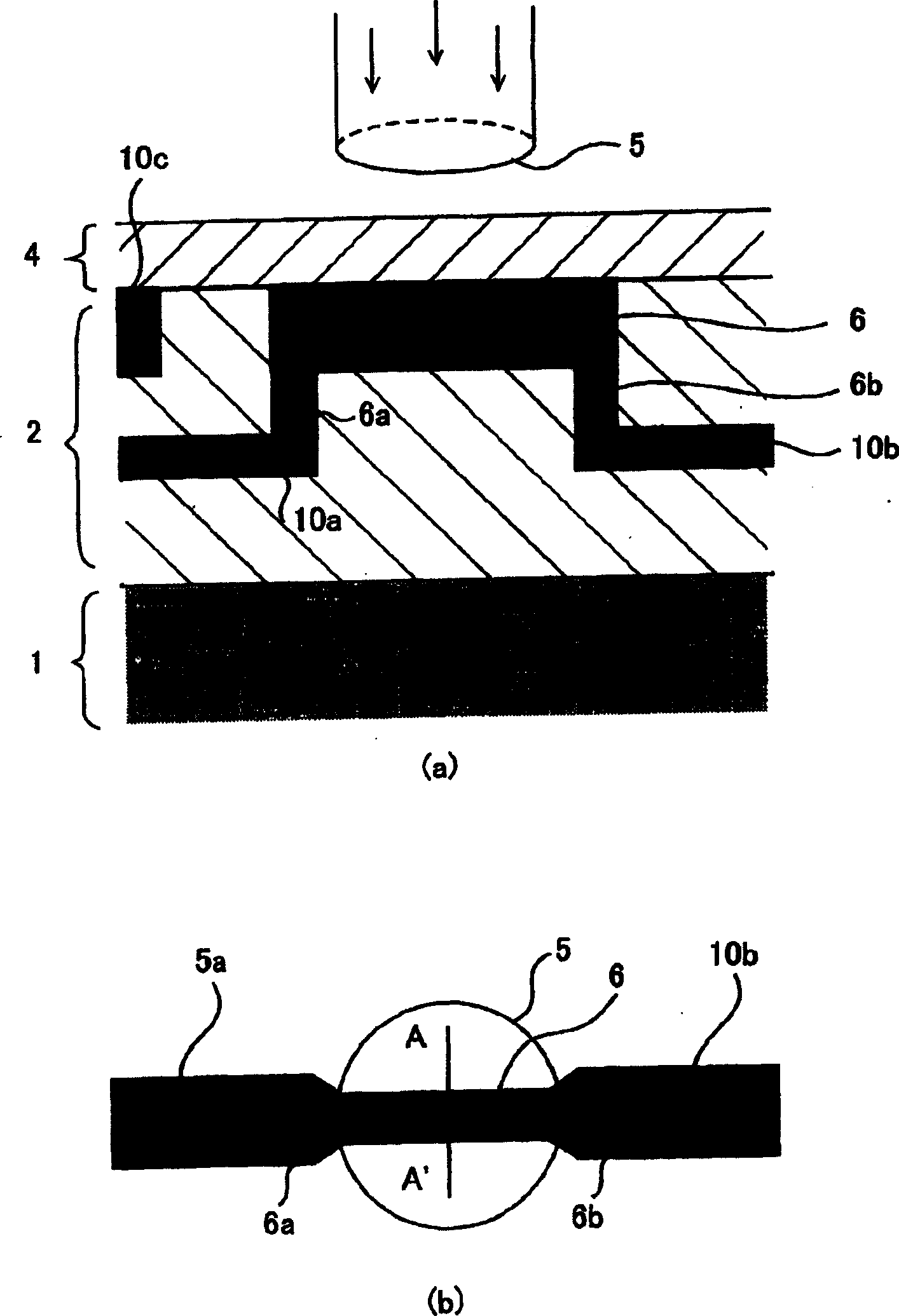

[0057] figure 1 (a) is a cross-sectional view showing a state in which the fuse related to the present invention is viewed from a lateral direction. In addition, figure 1 (b) shows the state which looked at the same area from directly above. In this figure, 2 is an interlayer insulating film (first insulating film) formed on the main surface (surface on which circuits and the like are formed) side of the silicon (semiconductor) substrate 1 . The interlayer insulating film 2 has been described as one...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap