Ecological road dust inhibitor

A dust suppressant and solvent technology, applied in the field of dust suppressants, can solve the problems of difficult biochemical degradation, single function, low cost performance, etc., and achieve the effect of improving water and soil environment, saving water resources, and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

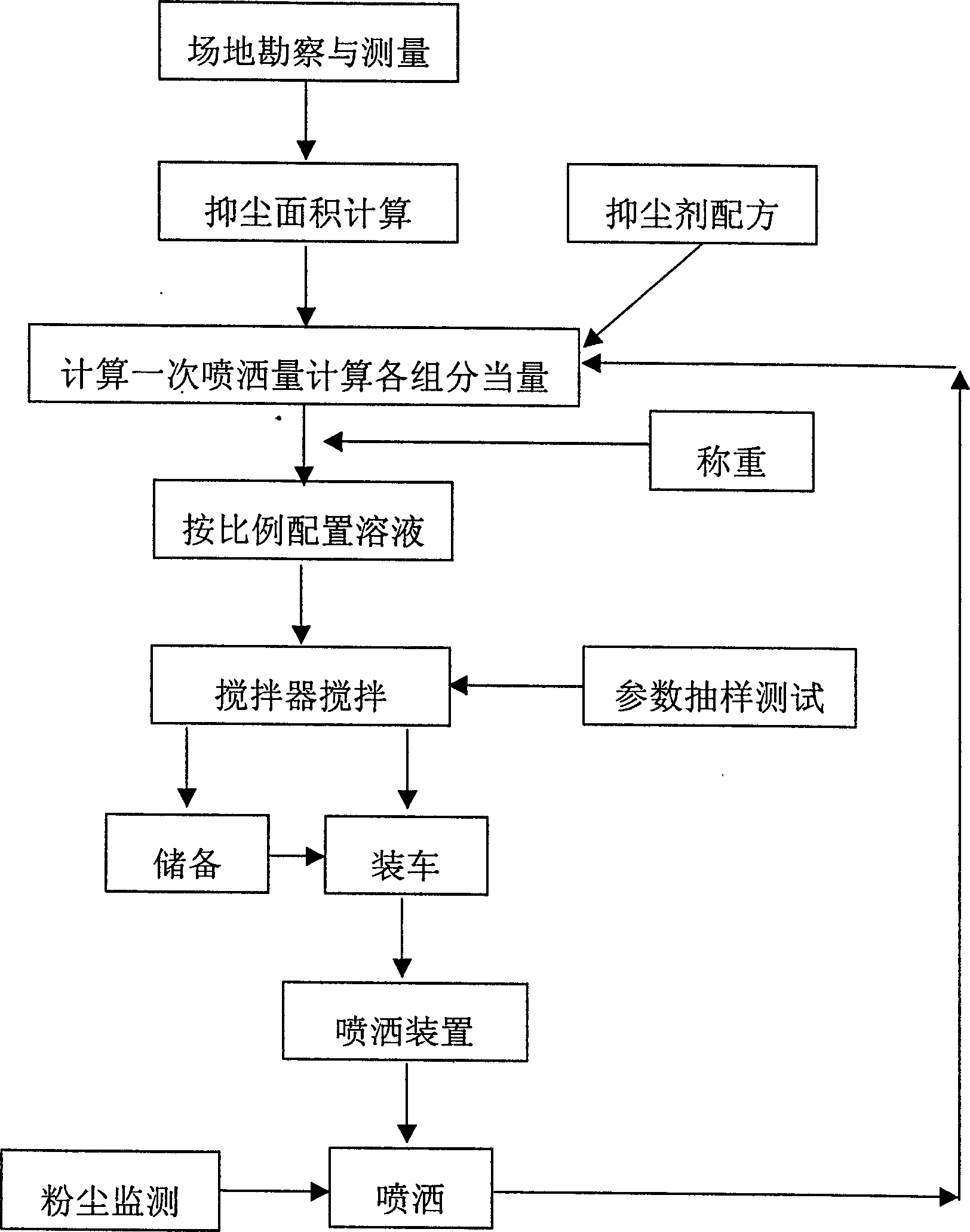

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: For muddy roads and fields.

[0013] Take 1.0 kg of carboxymethyl starch, 0.5 kg of sodium silicate, and 0.5 kg of glycerol, add them into 98 kg of water, and stir thoroughly at room temperature for 15-20 minutes to prepare 100 kg of dust suppressant. In the dust suppressant, the content of carboxymethyl starch is 1%, sodium silicate is 0.5%, glycerol is 0.5%, and water is 98%. As with most solubles, appropriate warming will speed up dissolution. At the same time, pre-soaking will help shorten the stirring time required for dissolution without affecting its performance. In order to reduce the stirring time, it can also be stirred into a high-concentration solution first, and then diluted with water to the required ratio. After the dust suppressant is completely dissolved, the preparation of the dust suppressant is completed. At this point, the prepared dust suppressant can be filled into sprinkler trucks or other spraying equipment for spraying.

Embodiment 2

[0014] Embodiment 2: for streets and cement roads.

[0015] Take 0.2 kg of carboxymethyl starch, 0.5 kg of sodium silicate, and 0.1 kg of glycerin, add them into 99.2 kg of water, and stir thoroughly at room temperature for 15-20 minutes to prepare 100 kg of dust suppressant. In the dust suppressant, the content of carboxymethyl starch is 0.2%, sodium silicate is 0.5%, glycerol is 0.1%, and water is 99.2%. Others are the same as embodiment 1.

Embodiment 3

[0016] Embodiment 3: For indoor cement floor and cladding.

[0017] Take 0.1 kg of carboxymethyl starch, 0.2 kg of sodium bicarbonate, and 0.1 kg of glycerin, add them into 99.6 kg of water, and fully stir at room temperature for 15-20 minutes to prepare 100 kg of dust suppressant. In the dust suppressant, the content of carboxymethyl starch is 0.1%, sodium bicarbonate is 0.2%, glycerol is 0.1%, and water is 99.6%. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com