Water-repelling foamed concrete preparing method and use thereof

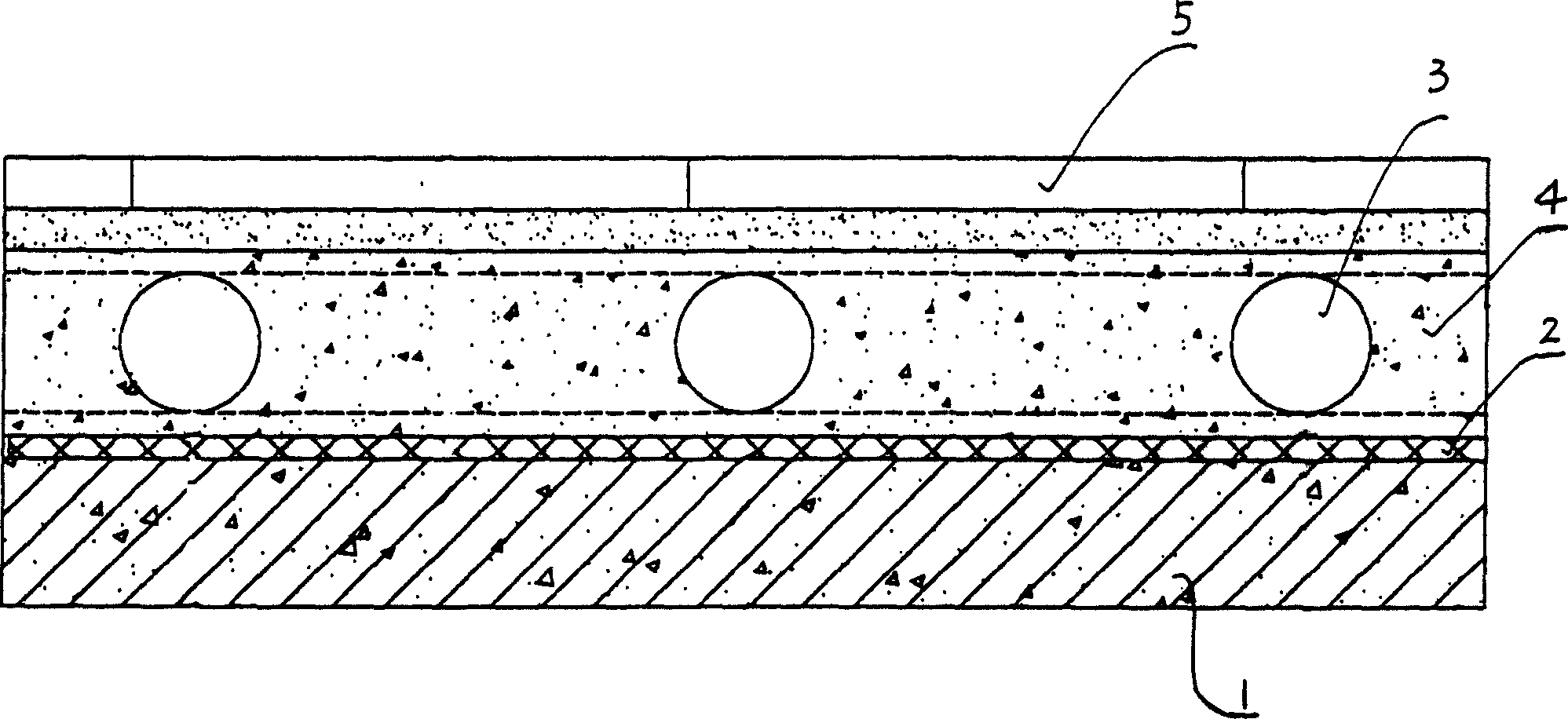

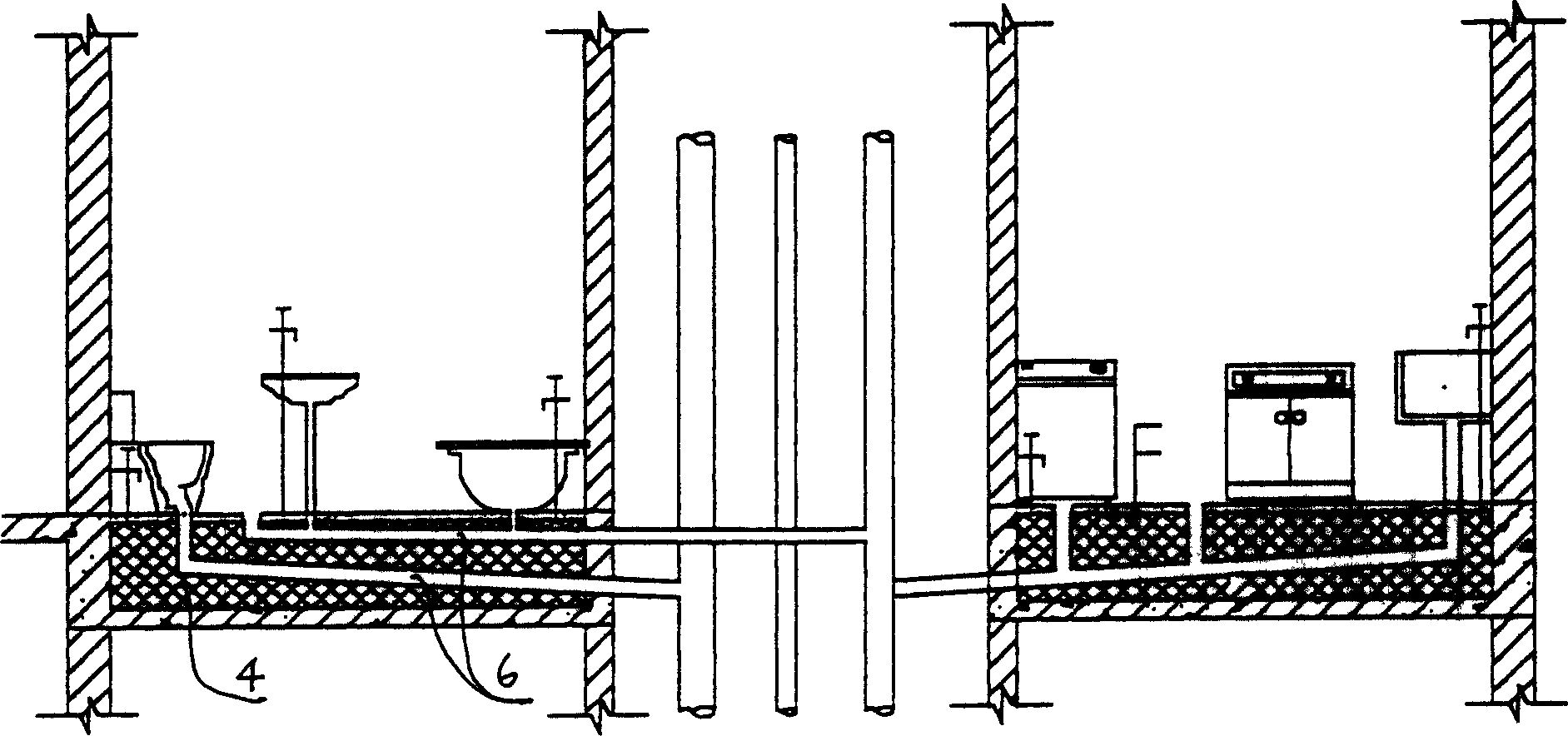

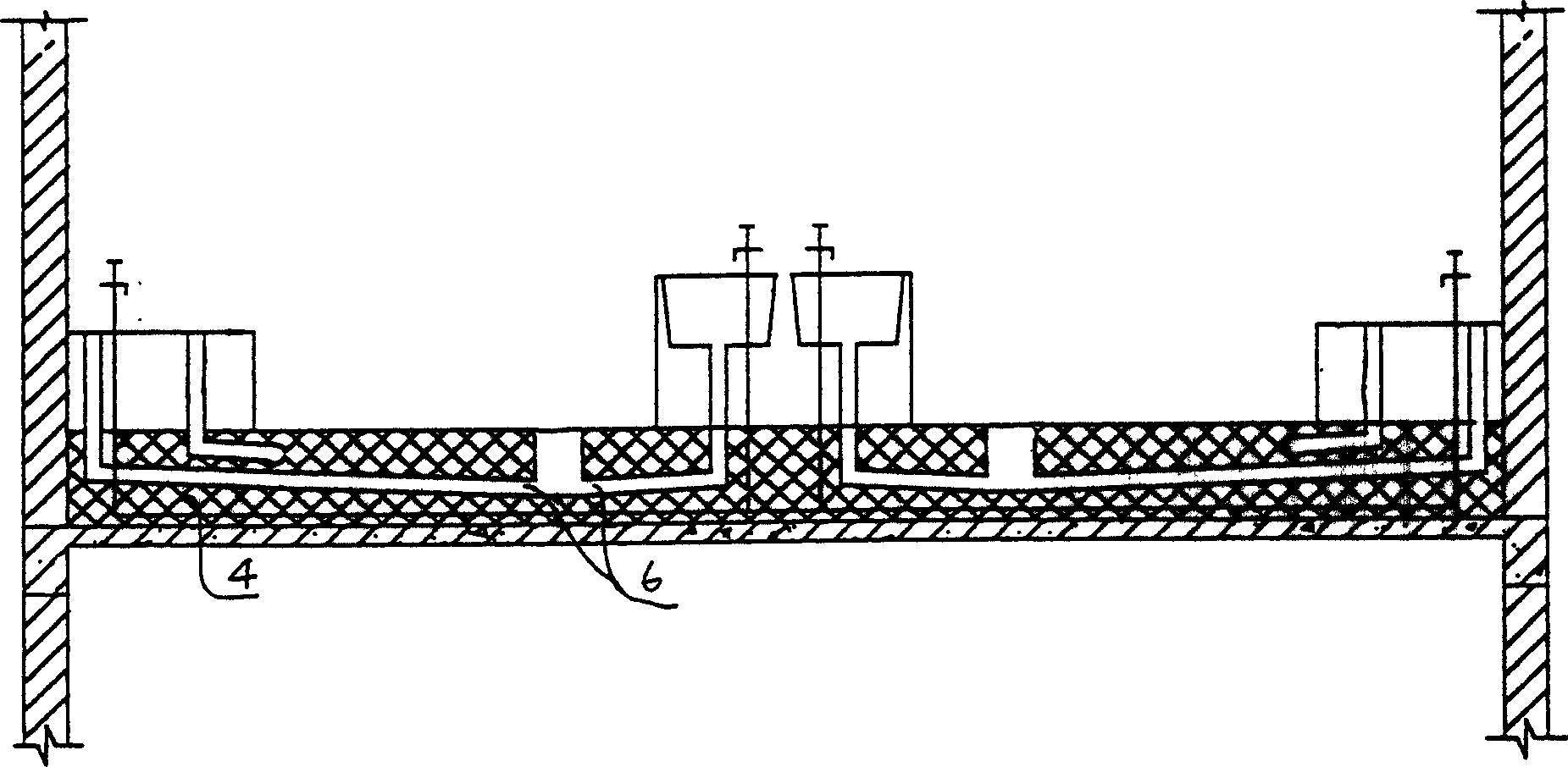

A foamed concrete and water-repellent technology, which is applied in the field of preparation of water-repellent foamed concrete, can solve the problem that the total thickness and weight may not meet certain requirements, and achieve the effects of simple and easy repair, good performance and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Take 10 kg of rosin and 20 kg of liquid polyvinyl alcohol, mix and heat to dissolve into a solution; heat and dissolve 5 kg of sodium hydroxide in 65 kg of pure water to form a solution, then put the above two solutions together in a container and heat to 120 °C , stirred and mixed to form a foaming agent; another 7 kg of potassium hydroxide was heated and dissolved in 72 kg of pure water to form a solution, then 21 kg of shellac was added, heated to 120°C, and dissolved under stirring with a mixer at a speed of 20r / min. Mix it into a water-repellent agent; then take 71 kg of the above-mentioned mixed foaming agent and 29 kg of water-repellent agent and mix and stir in a container to form a water-repellent foaming agent; take 10 kg of the water-repellent foaming agent mixed with 100 kg of water in Bubble in the bubbler for 15 minutes. In addition, add cement and water into the blade mixer at a weight ratio of 10:4 and stir to form cement slurry, then add polypropylene f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com