Process for preparing nanometer zirconium dioxide powder by double liquid phase hydrolysis

A zirconia and dual-liquid phase technology, applied in the direction of zirconia, can solve the problems of easy agglomeration of precursors, high cost, inability to obtain zirconia nano-powders, etc. effects of sex work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

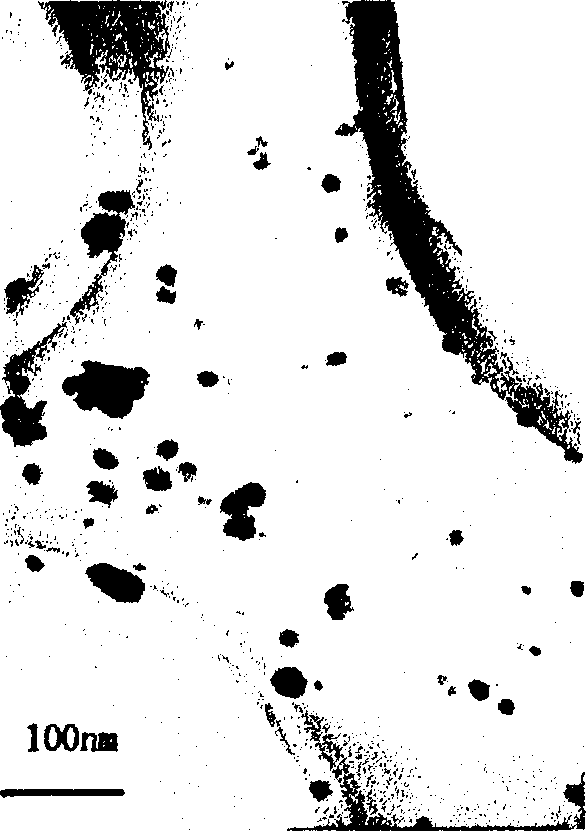

[0020] Example 1: 50ml toluene, add 0.15g AOT, stir for 10min; drop 0.1mol / L ZrOCl 2 5ml, stir vigorously, heat to 85°C and boil for 3 hours; when the volume of the liquid phase is less than 25ml, the precipitation of zirconium hydroxide in the organic phase will be obtained, dry to remove ZrO 2 ·nH 2 O moisture, fired at 600°C for 4 hours to obtain spherical nanoparticles of zirconia. figure 1 Shown is a transmission electron micrograph of zirconia.

example 2

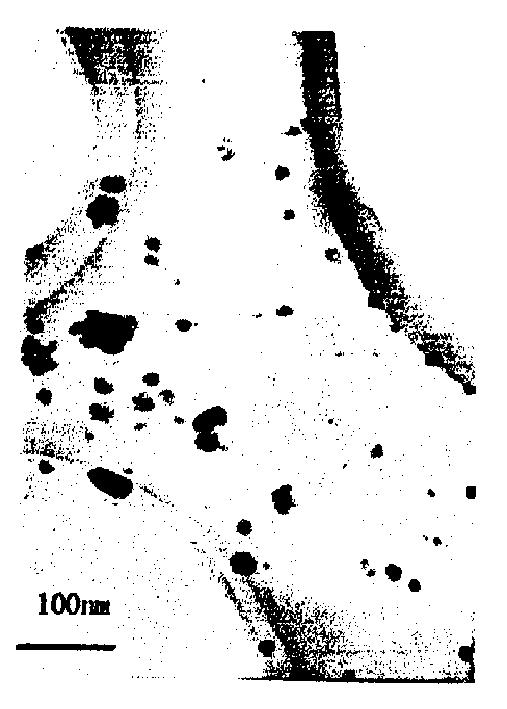

[0021] Example 2: 130ml toluene, add 0.45gAOT, stir for 10min; drop 0.5mol / L ZrOCl 2 20ml of aqueous solution, vigorously stirred and boiled at 85°C for 5 hours; the solution was turbid, the condensate was recovered, the liquid was separated, the lower layer was hydrochloric acid solution, the upper layer was toluene, hydrochloric acid and toluene were separated; when the water phase was no longer precipitated, the mixture was precipitated and dried , remove ZrO 2 ·nH 2 O moisture, to obtain primary embryo body, 700 ° C for 2 hours to obtain zirconia spherical nanoparticles.

example 3

[0022] Example 3: 130ml of toluene, add 1.0g of AOT, stir for 10min and drop in 0.8mol / L of ZrOCl 2 20ml of aqueous solution, vigorously stirred and boiled at 85°C for 8 hours; the solution was turbid, the condensate was recovered, the liquid was separated, the lower layer was hydrochloric acid solution, the upper layer was toluene, and hydrochloric acid and toluene were separated; when the water phase was no longer precipitated, the mixture was precipitated and dried , remove ZrO 2 ·nH 2 O moisture to obtain the primary embryo body, which was fired at 750°C for 2 hours to obtain spherical nanoparticles of zirconia.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com