Method for making wooden parts of musical instrument, wooden parts for musical instrument use and musical instrument including the same

A musical instrument and wood technology, applied in the field of manufacturing wooden pieces for musical instruments, can solve problems such as difficulty in adjustment, increased cost, difficulty, etc., and achieve the effects of improving yield, reducing material cost, and suppressing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

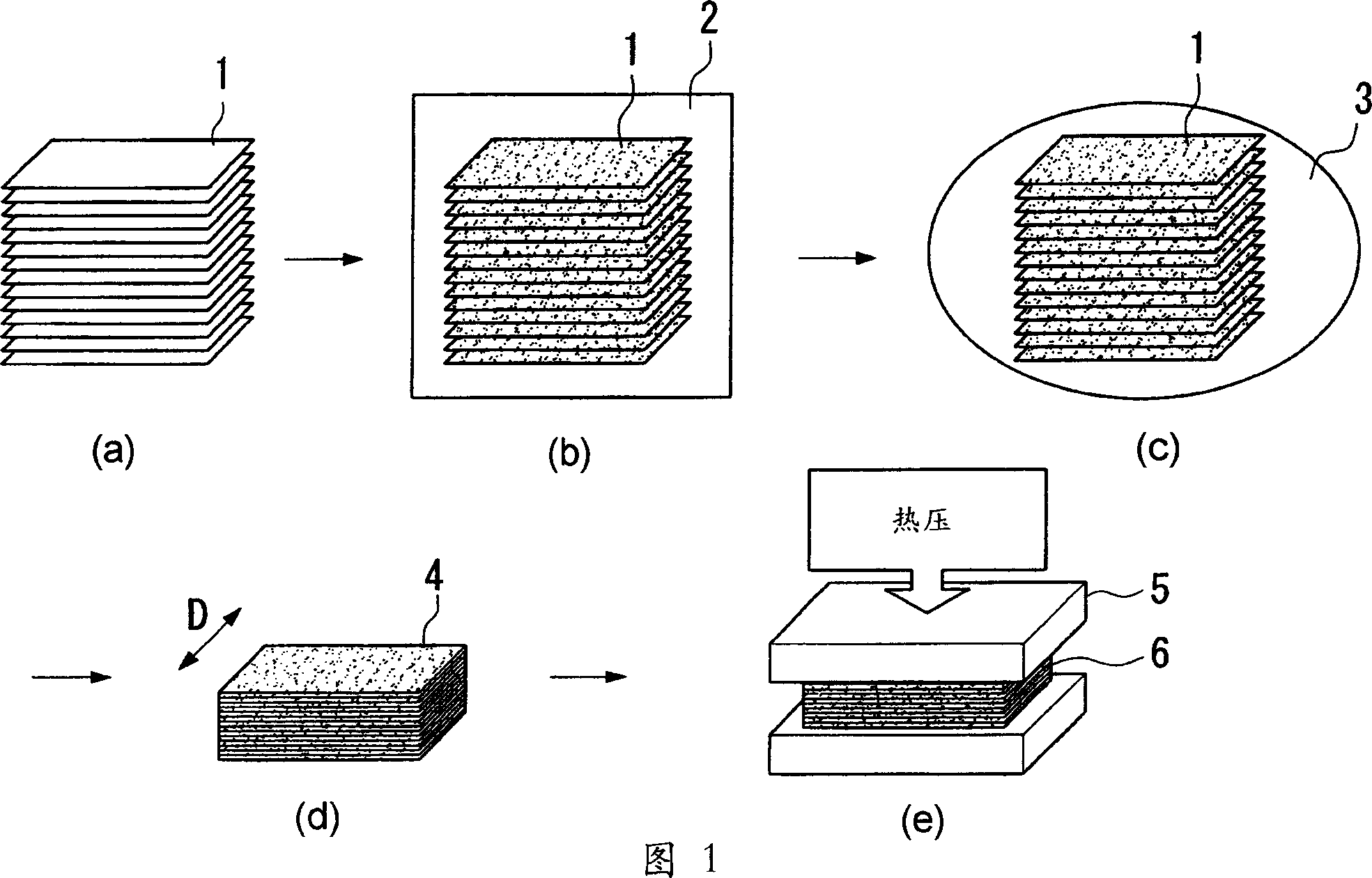

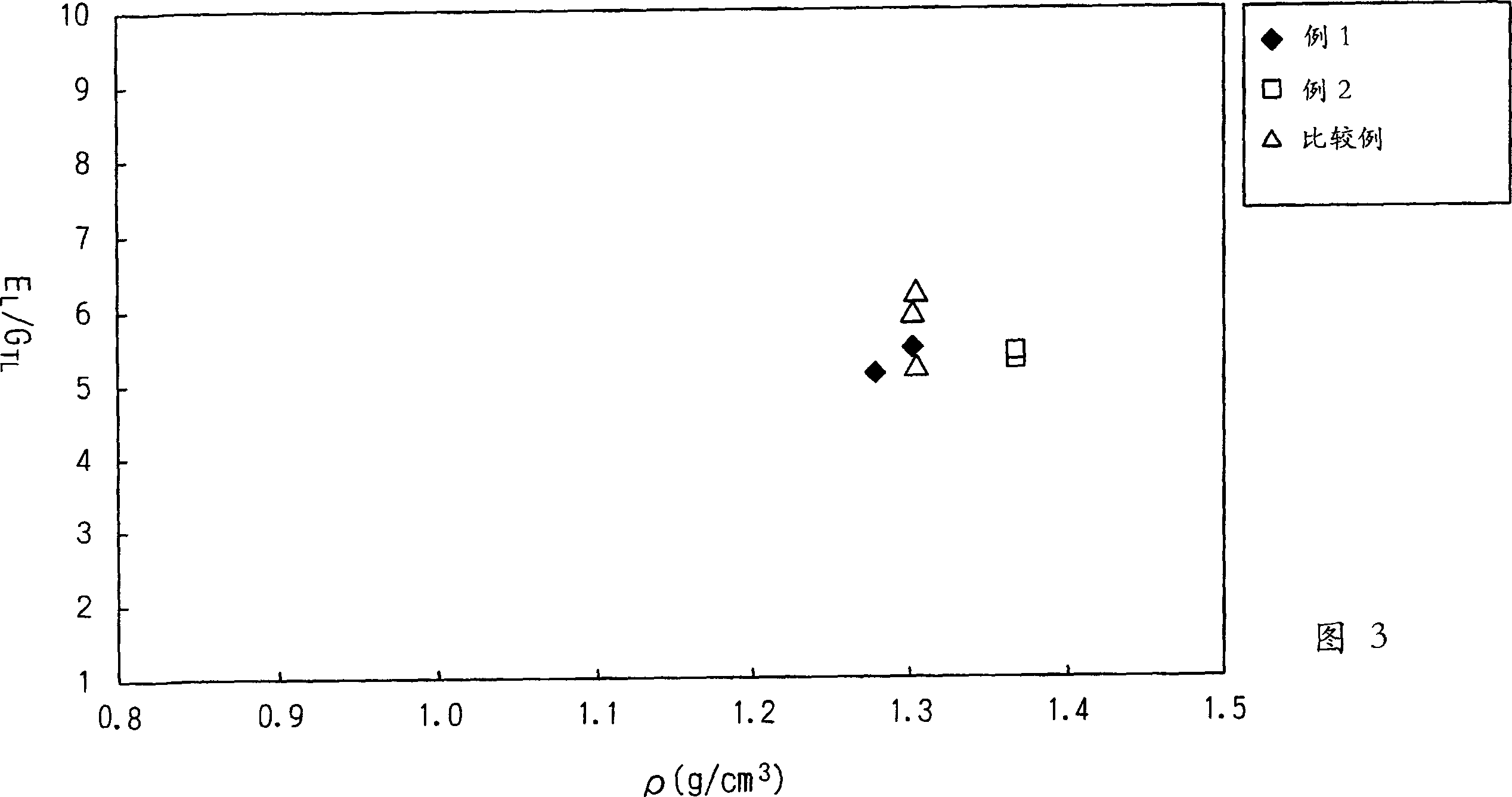

[0091] The honey resin aqueous solution was applied to the entire surface of 600 wooden (youous wood) board members each having a length of 180 cm, a width of 90 cm and a thickness of 0.6 mm. Align the fiber directions of these wooden board parts and place them in a pile. Then, at a temperature of 130°C and 20kg / cm 2 Hot pressing under high pressure. The melamine resin hardens and the planks are glued together to form a laminate. The density of this laminate is 0.5g / cm 3 . Utilize slicer, on the vertical direction relative to the top face of wood board pile, laminated body is sliced along the fiber direction of wood board, obtain laminated wooden board parts (the length of each board is 150cm, width is 30cm, thickness is 0.6 mm). Then, these laminated wooden board members were immersed in the same aqueous solution of melamine resin as used in the above process for 2 hours to impregnate the wooden board members with melamine resin. Then align the fiber direction of thes...

example 2

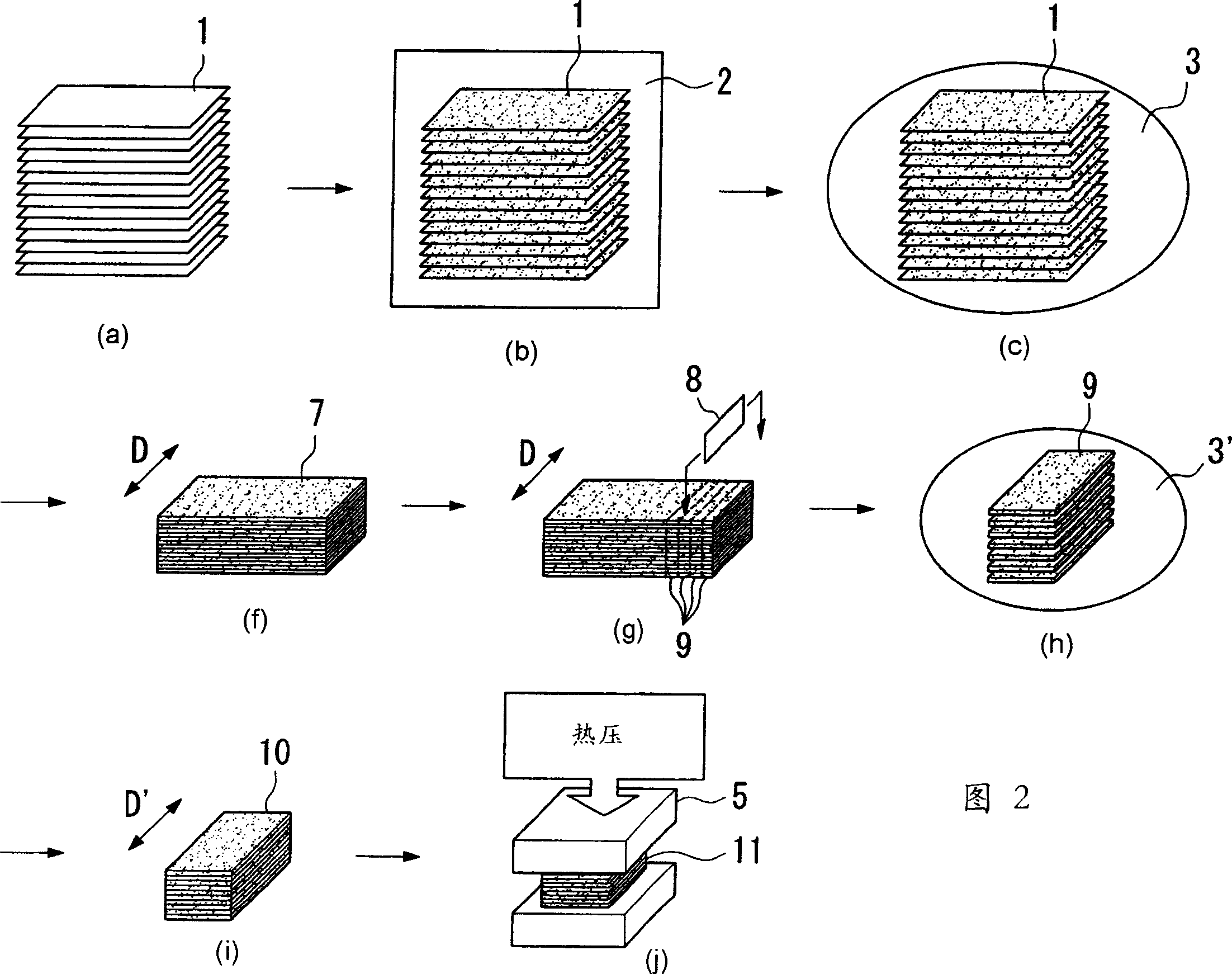

[0093] The honey resin aqueous solution was coated on the entire surface of 600 wooden board (youous wood) parts, each of which had a length of 180 cm, a width of 90 cm, and a thickness of 0.6 mm. Align the fiber directions of these wooden board parts and place them in a pile. Then, at a temperature of 130°C and 10-20kg / cm 2 Hot pressing under high pressure. The melamine resin hardens and the planks are bonded together to form a laminate with a density of 0.6g / cm 3 . Using a slicer, slice the laminate along the fiber direction of the planks in a vertical direction relative to the top surface of the stack of planks to obtain laminate parts (the length of each plank is 150 cm, the width is 30 cm, and the thickness is 0.25 mm) . Then, these laminated wooden board members were alternately stacked with paper (0.06 mm in thickness) impregnated with the same aqueous melamine resin solution as used in the above process for 1 hour. The fiber directions of these laminated wooden bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com