Mesoporous molecular sieve cortaining beta zeolite secondary constitutional unit and preparing method thereof

A secondary structural unit, mesoporous molecular sieve technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, non-metallic elements, etc., can solve problems such as unseen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

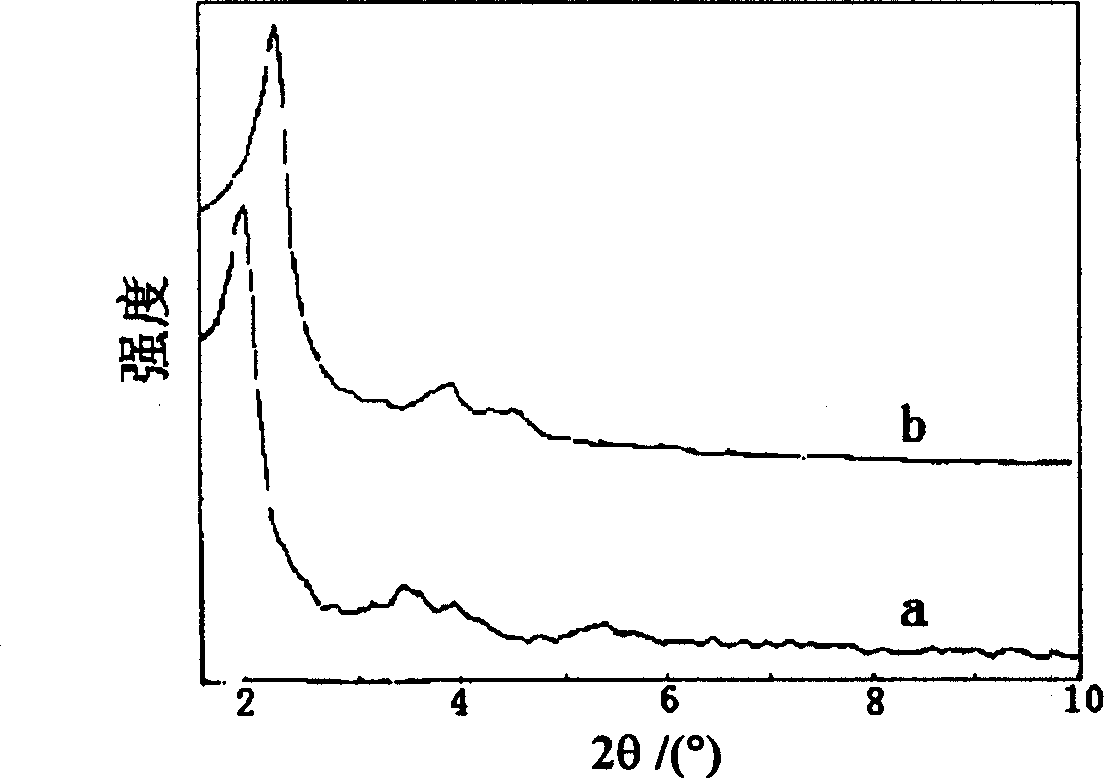

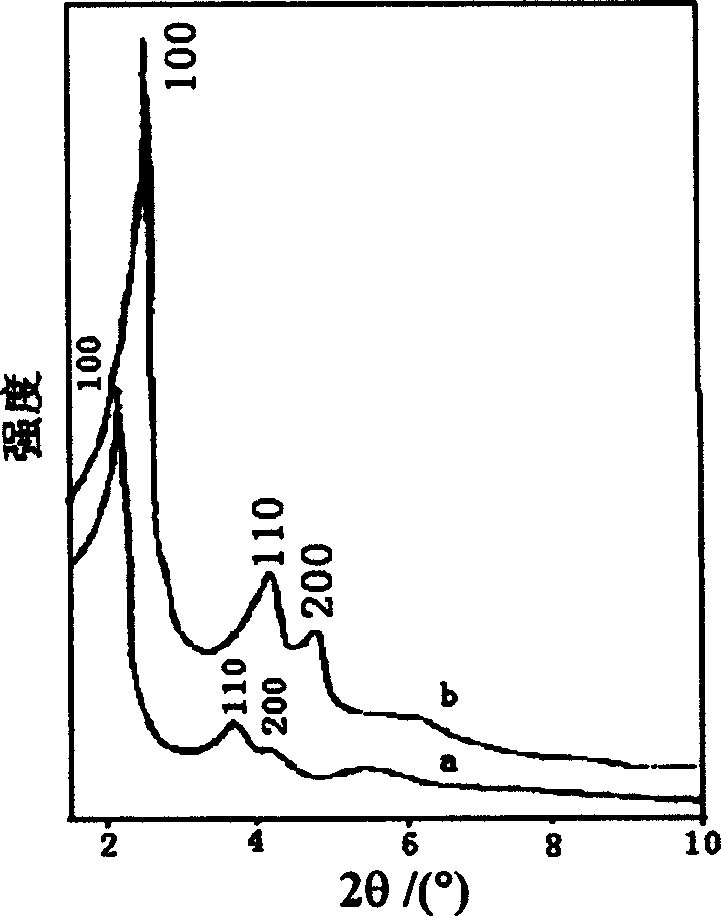

example 1

[0022] 0.134g pseudo-boehmite (51wt%Al 2 o 3) was dissolved in 5.0g of 25wt% tetraethylammonium hydroxide solution, then 1.0g of white carbon black was added, stirred evenly, then put into a stainless steel reaction kettle with a polytetrafluoroethylene liner, and stirred and reacted in an oil bath at 135°C 131h. Add the above-mentioned pretreated precursor dropwise to the mixed solution of CTAB and OP-10. At this time, the molar composition of the synthetic mixture is: 1.0SiO 2 : 0.04Al 2 o 3 :0.25(TEA) 2 O: 0.21CTAB: 0.04OP-10: 96H 2 O. Then adjust the pH to 9.0 with dilute sulfuric acid, and crystallize at 110 °C for 36 h to obtain the initial gel SiO 2 / Al 2 o 3 25 SBU(β)-MCM-41 mesoporous molecular sieve.

example 2

[0024] Weigh 0.0335g pseudo-boehmite (51wt%Al 2 o 3 ), dissolved in 5.0g 25wt% tetraethylammonium hydroxide solution, then add 1.0g white carbon black, stir evenly and put it into a stainless steel reaction kettle with a polytetrafluoroethylene liner, stir and react at 150°C 16h. Add the above-mentioned pretreated precursor dropwise to the mixed solution of CTAB and OP-10. At this time, the molar composition of the synthetic mixture is: 1.0SiO 2 : 0.01Al 2 o 3 :0.25(TEA) 2 O: 0.12CTAB: 0.04OP-10: 96H 2 O. Then adjust the pH to 9.5 with dilute sulfuric acid, and crystallize at 95 °C for 32 h to obtain the initial gel SiO 2 / Al 2 o 3 100 SBU(β)-MCM-41 mesoporous molecular sieve.

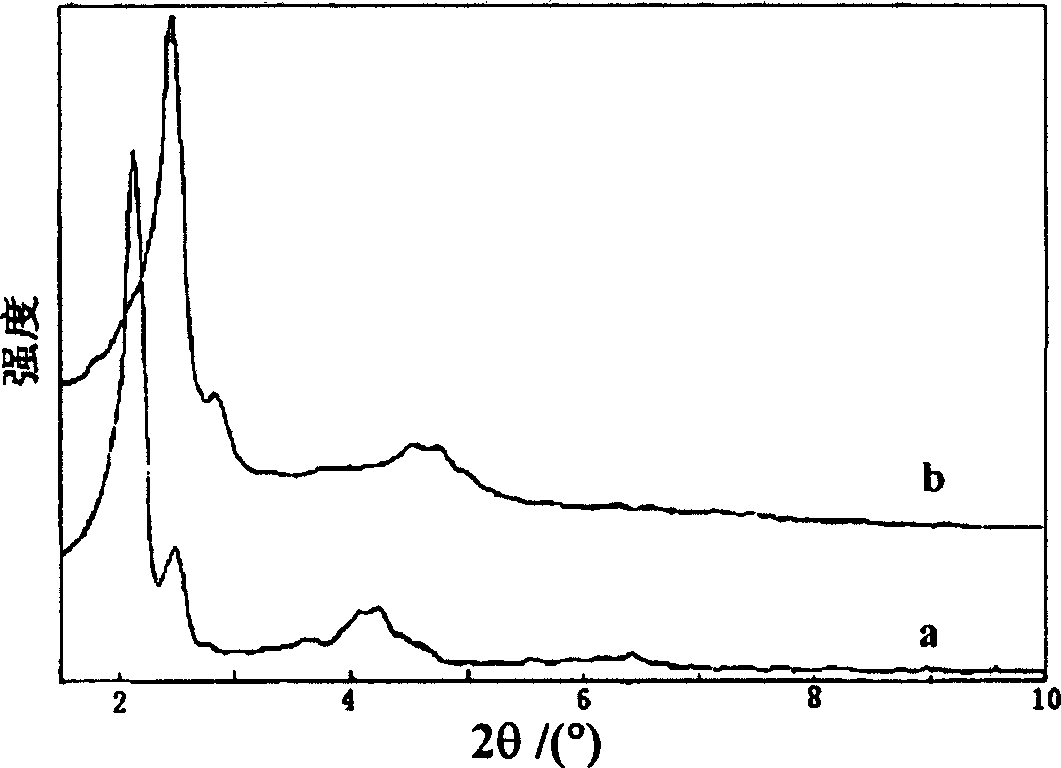

example 3

[0026] 0.0335g pseudo-boehmite (51wt%Al 2 o 3 ) was dissolved in 4.52g of 25wt% tetraethylammonium hydroxide solution, and then 1.0g of white carbon black was added, stirred evenly, put into a stainless steel reaction kettle with a polytetrafluoroethylene liner, and stirred and reacted at 135°C for 23h. Add the above pretreated precursor dropwise to the mixed solution of CTAB and OP-10, then the molar composition of the synthetic mixture is: 1.0SiO 2 : 0.01Al 2 o 3 :0.23(TEA) 2 O: 0.34CTAB: 0.043OP-10: 64H 2 O. Then adjust the pH to 11.8 with dilute sulfuric acid, and crystallize at 105 °C for 68 h to obtain the initial gel SiO 2 / Al 2 o 3 100 SBU(β)-MCM-48 mesoporous molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com