Semiconductor optical modulator and laser with optical modulator

An optical modulator, laser technology, applied in semiconductor lasers, lasers, laser parts and other directions, can solve problems such as the influence of operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0064] First, a first embodiment of the present invention will be described.

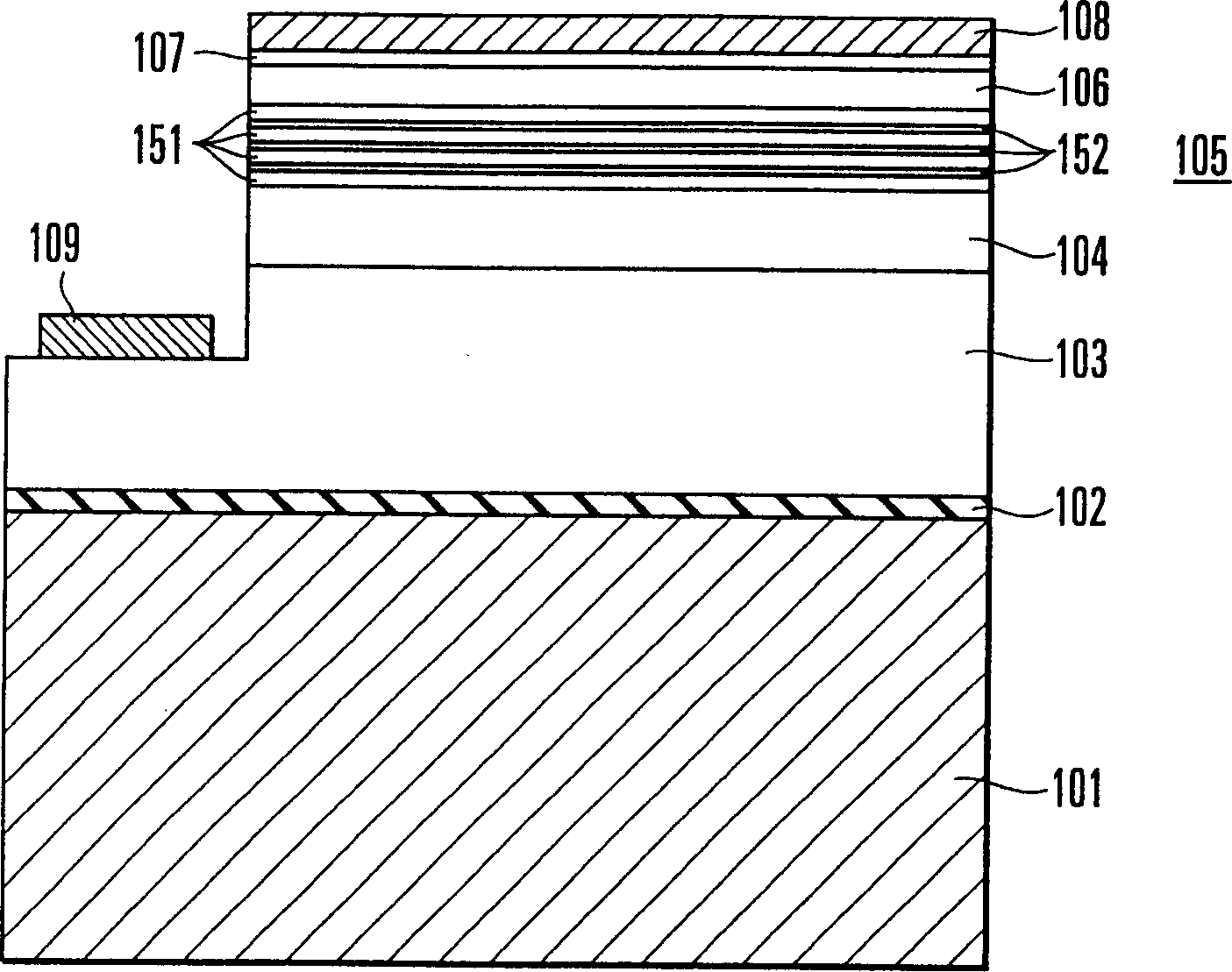

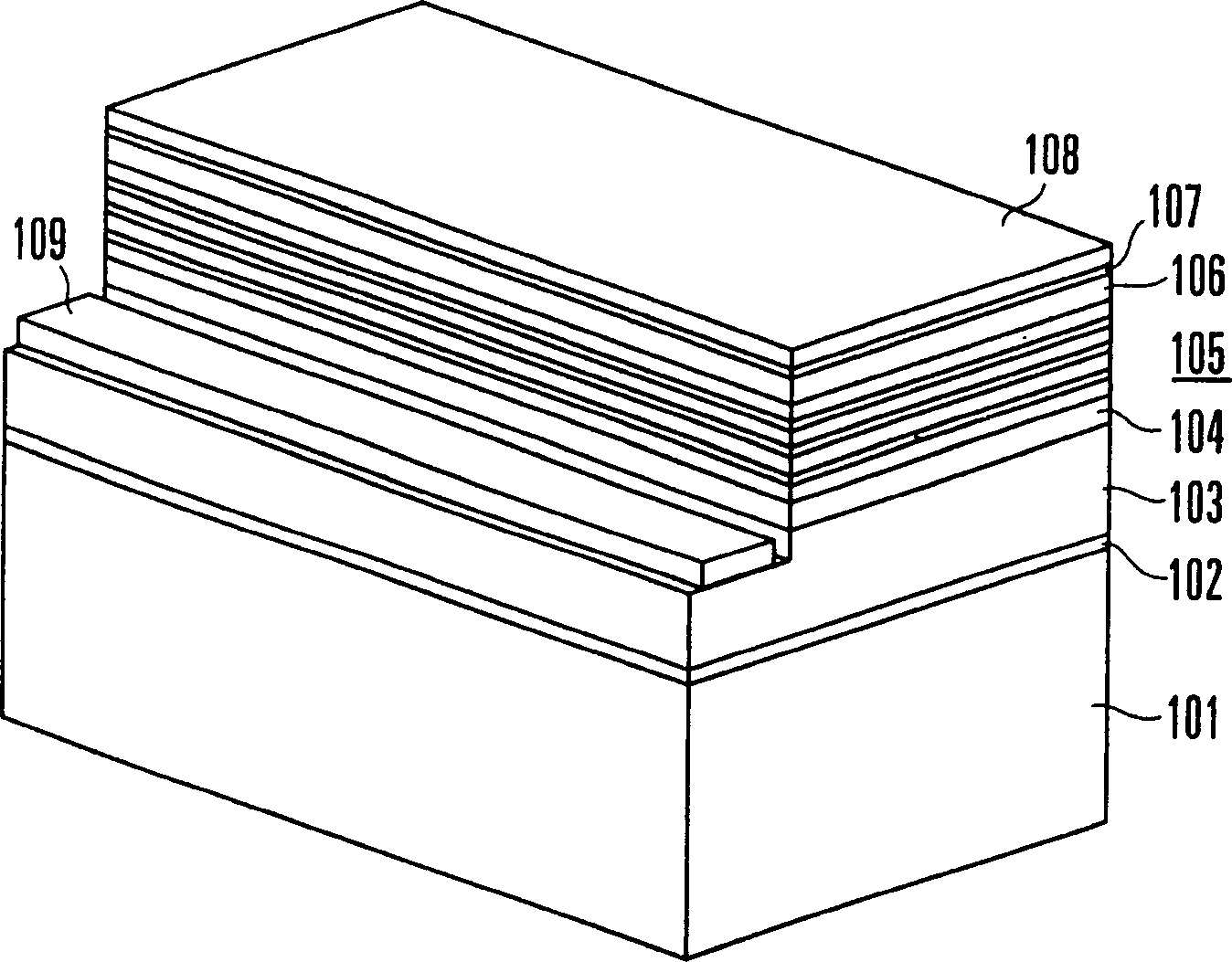

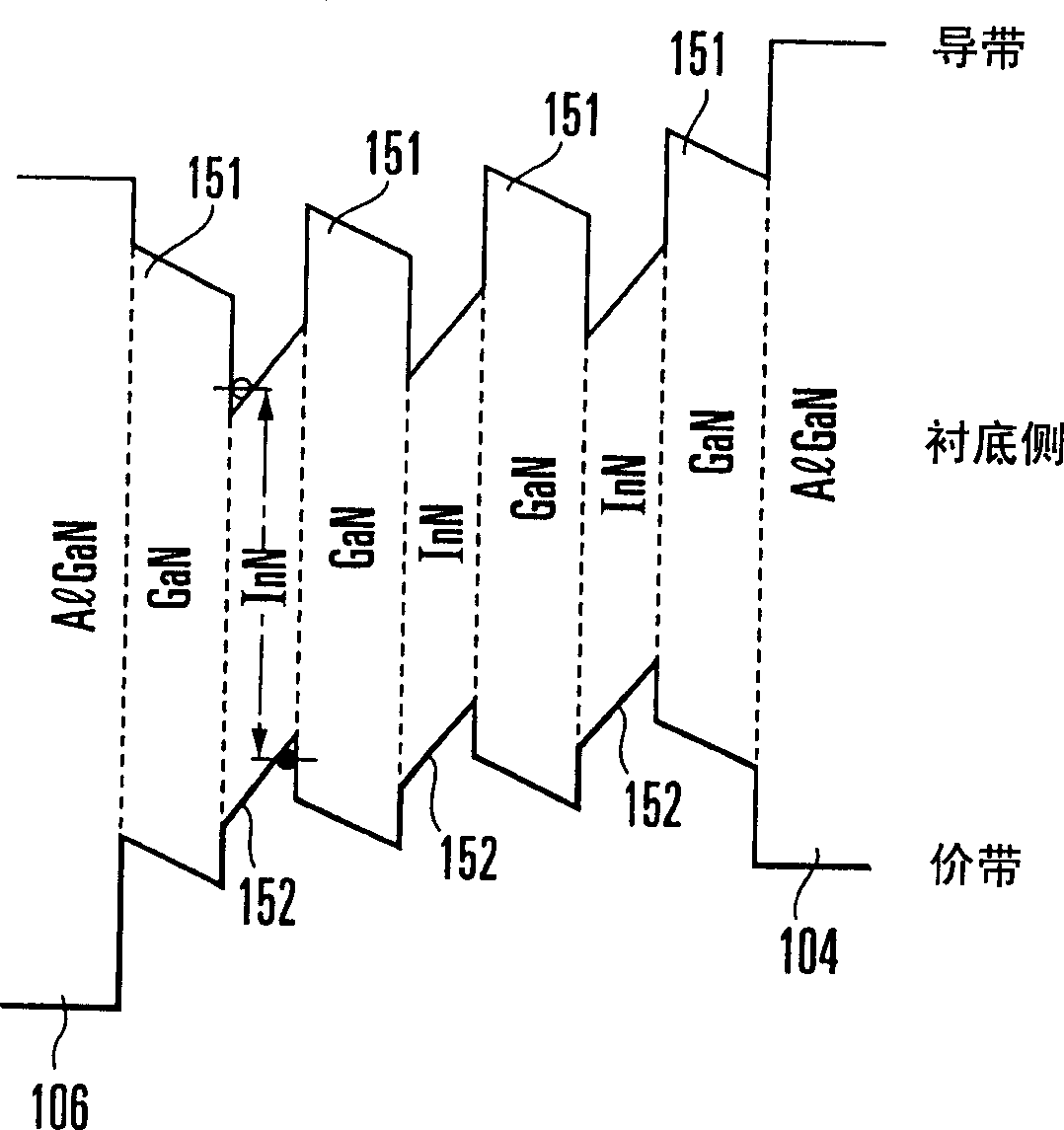

[0065] Figure 1A An embodiment according to the present invention schematically shows a structural example of a semiconductor light modulator. Figure 1B The structure of the semiconductor light modulator is schematically shown. Note that in the following description, compound semiconductor materials such as GaN, AlGaN, AlN, and InN are single crystals unless otherwise specified.

[0066] The semiconductor optical modulator is composed of (0001)-oriented sapphire (α-Al 2 o 3 crystal) with a buffer layer 102, an electrode layer 103, and a cladding layer 104 on the nitrided surface of a 330-μm-thick single crystal substrate 101. The buffer layer 102 is 20 nm thick and made of GaN. The electrode layer 103 is 4 μm thick and made of Mg-doped p-type GaN. The cladding layer 104 is 0.5 μm thick, p-type Al doped with Mg 0.1 Ga 0.9 N made. It should be noted that the single crystal substrate 101 is ...

no. 2 example

[0140] Next, another embodiment of the present invention will be described.

[0141] Figure 12 It schematically shows a structural example of a semiconductor light modulator according to another embodiment of the present invention.

[0142] In this semiconductor light modulator, a light absorbing region in the form of a ridge is formed on the surface of a 300-μm-thick substrate 1101 made of n-type GaN. The light-absorbing region consists of the following: a lower cladding layer 1102, about 1.5 μm thick, made of Si-doped n-type Al 0.1 Ga 0.9 Made of N; 0.5-μm-thick lower SCH (Separation Suppressed Heterostructure) layer 1103 made of non-doped InGaAlN; light-absorbing layer 1104 with MQW structure; 5-μm thick made of non-doped InGaAlN The upper SCH layer 1105; p-type Al doped by Mg 0.1 Ga 0.9 a 1.5-μm-thick upper cladding layer 1106 made of N; and a 0.1-μm-thick contact layer 1107 made of Mg-doped p-type GaN. The light absorbing layer 1104 is made of In by alternating sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com