Method for processing cobalt coated nickel hydroxide

A treatment method and technology of nickel hydroxide, applied in structural parts, circuits, electrodes of alkaline batteries, etc., can solve problems such as poor treatment effect and particle adhesion, and achieve the prevention of particle agglomeration, the uniform composition of the mixture, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

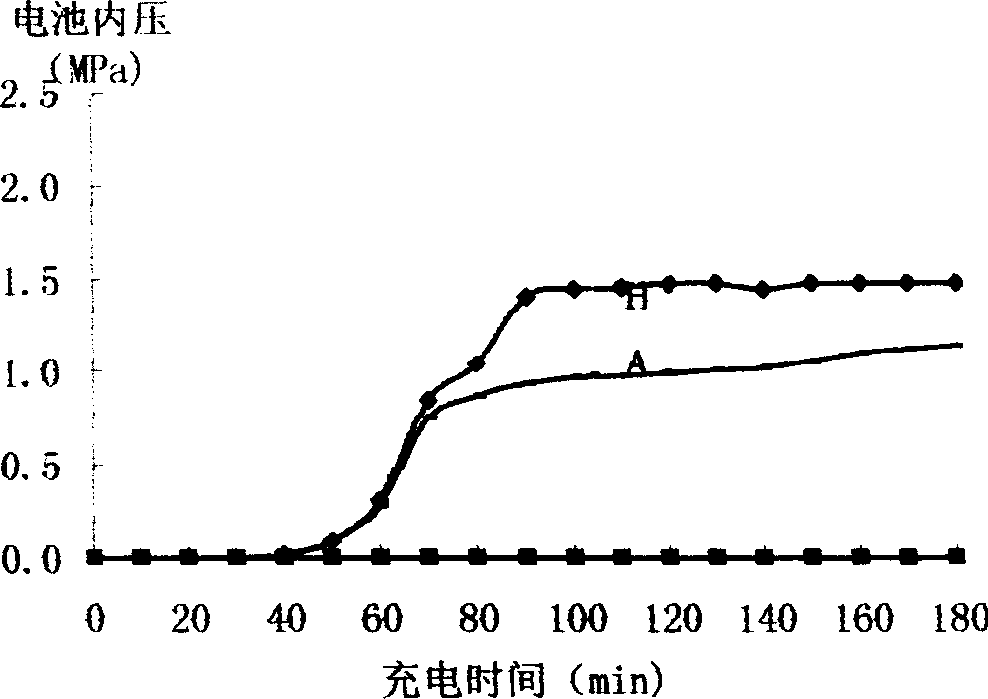

[0034] Get commercially available nickel hydroxide particles coated with cobalt hydroxide with a cobalt content of 5% on the surface, numbered h, put it into a conical container from the feeding port of the conical propeller mixer, and control the loading so that the loaded The upper surface of the incoming granular material is under the nozzle, close the feeding port, and rotate the rocker arm and propeller, while spraying the alkaline aqueous solution from the nozzle. The sprayed caustic alkali solution adheres to the surface of the granular matter stirred by the propeller and penetrates the cobalt hydroxide on the particle surface. After the caustic alkali aqueous solution is completely sprayed, continue stirring for 15 minutes, and then discharge the granular matter from the discharge port.

[0035] Load the mixed granular matter from the feeding port of the screw-feeding machine sieve, feed compressed gas with a pressure of 0.1Mpa through the air inlet, start the motor to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com