Packaging structure of organic electroluminescent cell and making process thereof

A technology of electroluminescence components and packaging structures, which is applied in the direction of electrical components, electroluminescence light sources, electric light sources, etc., and can solve problems such as destruction, high requirements for moisture and oxygen absorption efficiency, and limited space for desiccant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] first preferred embodiment

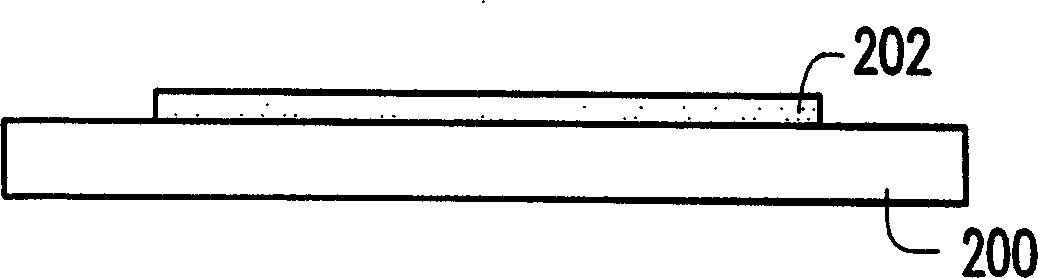

[0047] Figure 2A to Figure 2D It is a schematic diagram of the packaging process of the organic electroluminescent device according to the first preferred embodiment of the present invention. Please refer to Figure 2A First, a substrate 200 is provided, and an organic electroluminescent film 202 is provided on the substrate 200 . Wherein, the organic electroluminescent thin film 202 is, for example, a transparent anode, a metal cathode, an organic electroluminescent layer, an electron transport layer (ETL), a hole transport layer (HTL), an electron injection layer (EIL), a hole injection layer (HIL). )Wait. In addition, the organic electroluminescence thin film 202 is, for example, a small molecule organic light emitting material or a polymer organic light emitting material.

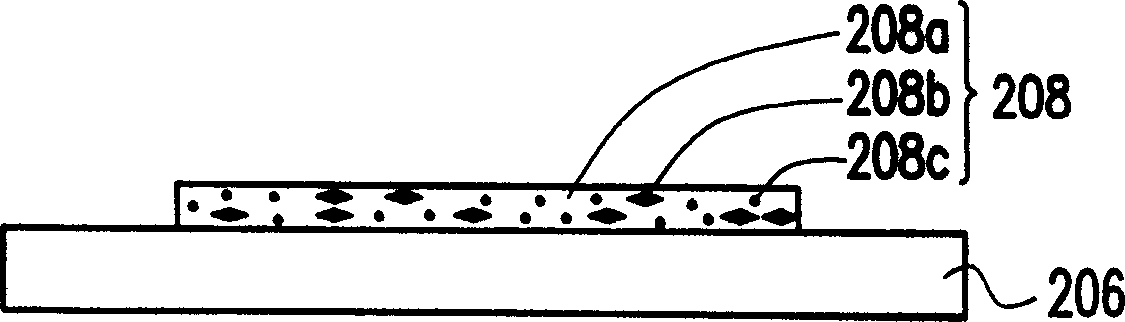

[0048] Then please refer to Figure 2B , provide a cover plate 206, and form a liquid desiccant 208 on the cover plate 206, the forming method is, for example, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com