High temperature metal boat and method of plating tin doped indium oxide transparent condutive membrane

A technology of transparent conductive film and tin-doped indium oxide, which is applied in metal material coating process, sputtering plating, vacuum evaporation plating, etc., can solve the problem that affects the stability of the plating process and does not form a process flow with industrial value and other issues, to achieve good market prospects and application value, good chemical stability, and easy control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

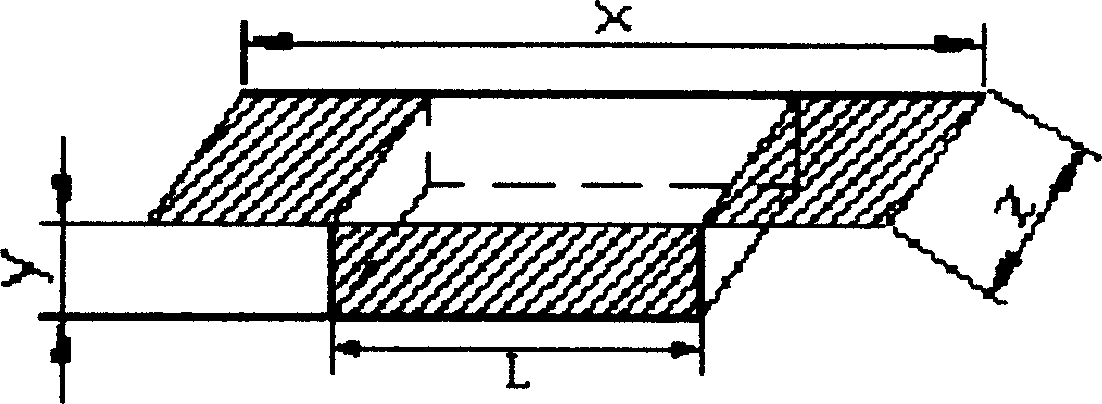

[0020] see first figure 1 , figure 1 It is a schematic structural diagram of the high-temperature evaporation boat made of tantalum sheets in the present invention. The present invention uses tantalum sheets that have been annealed at a high temperature of 900--1200°C to make the evaporation boat; the thickness of the tantalum sheets is 3mm.

[0021] The evaporation boat is made of tantalum; the evaporation boat is a long ark, and the relationship between its size and structure is:

[0022] The total length of the evaporation boat, including the two fins, is (88±3)mm,

[0023] The length of the boat tank: depth: width = (45 ± 2) mm: 10 ± 3) mm: (24 ± 3) mm,

[0024] The thickness of the tantalum sheet is 3mm.

[0025] The size change range of the above boat has been proved to be valid data through experiments. According to our experimental results, if the depth is small, the heat gathering performance of the whole boat is poor. Therefore, if we want to obtain enough heat to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com