Chitosan oligosaccharide containging pesticide composition and its application

A pesticide composition and the technology of the composition are applied in the field of agriculture and can solve problems such as the lack of chitosan oligosaccharides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

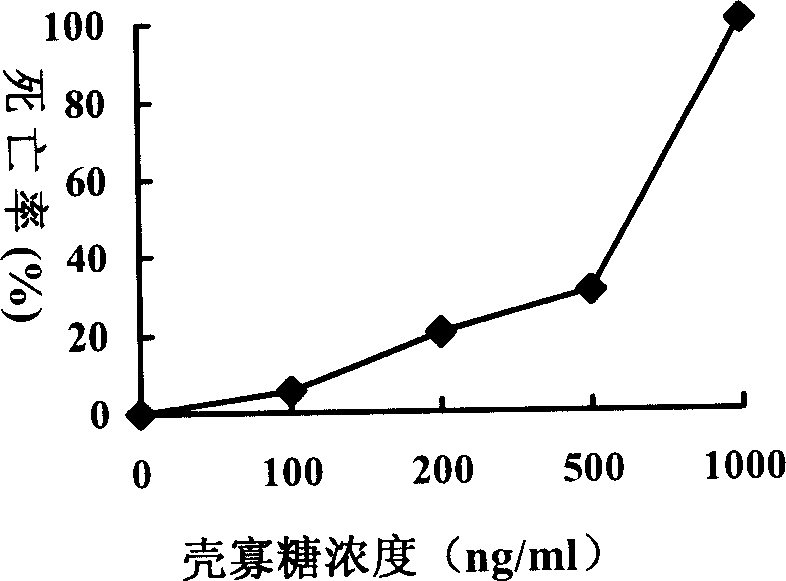

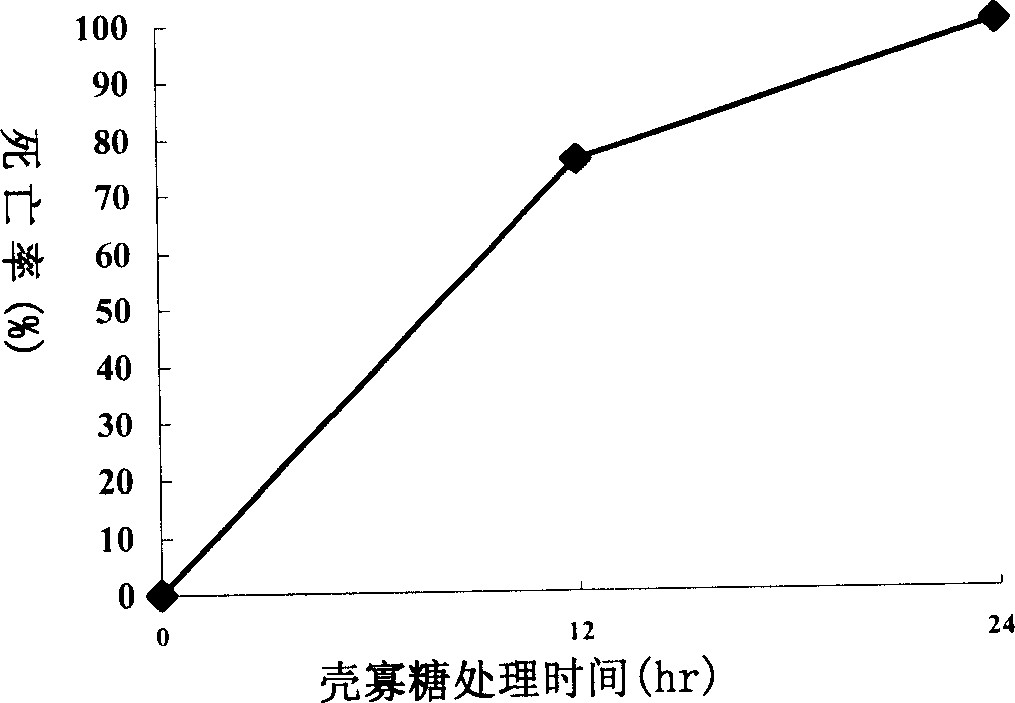

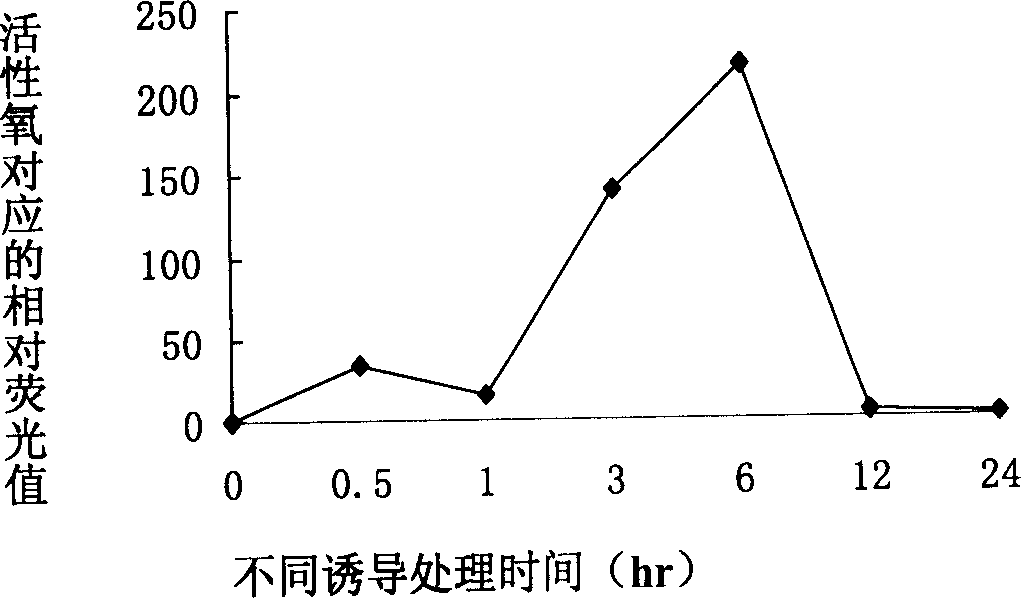

Examples

preparation example Construction

[0039] The preparation method of chitosan oligosaccharides is known, and a preferred solution is as follows: solid chitin or clam shells, shrimp shells are washed, dried and crushed powder → press 1:10 in a sealed mixer with cooling facilities Add concentrated hydrochloric acid → 30-45°C and stir for 3-12 hours until all the chitin is dissolved → cool the supernatant suspension in a low-temperature container to 10-20°C → gradually add 5N NaOH to pH 3.0 to produce NaCl precipitation, and Soluble oligosaccharide amine in the supernatant → filter to remove salt (salt can be recycled as industrial salt) → oligosaccharide amine solution is dehydrated and dried to become the finished product → powder is dried and stored.

[0040] The composition of the present invention usually contains a total amount of 0.0005 to 99% by weight of active ingredients (i.e., chitooligosaccharides). Concentrated pesticides have a relatively high active ingredient content, such as 80-90%, while diluted pest...

Embodiment 1

[0063] Preparation of rice suspension cells

[0064] Rice suspension cells were cultured in the dark on a 26°C shaker (80 rpm) in N6 liquid medium, and the fresh medium was replaced every 7-10 days.

[0065] The formula of N6 liquid medium is as follows:

[0066] KNO 3 2.83g / L (NH 4 ) 2 SO 4 0.463g / L

[0067] KH 2 PO 4 0.4g / L MgSO 4 ·7H 2 O 0.185g / L

[0068] CaCl 2 ·2H 2 O 0.166g / L MnSO 4 ·H 2 O 3.3mg / L

[0069] ZnSO 4 ·7H 2 O 1.5mg / L H 3 BO 3 1.6mg / L

[0070] KI 0.8mg / L

[0071] FeSO4·7H 2 O 28mg / L Na 2 EDTA 37mg / L

[0072] Niacin (B5) 0.5mg / L Thiamine·HCl(B1) 0.1mg / L

[0073] Pyridoxine HCl(B6) 0.5mg / L Inositol ester 100mg / L

[0074] Sucrose 30g / L 2,4-D 2mg / L

[0075] Proline 2.3g / L Tryptophan 50mg / L

[0076] pH5.8

Embodiment 2

[0078] Preparation of Chitooligosaccharides and Mother Liquor

[0079] The preparation process of chitooligosaccharides is as follows:

[0080] Solid chitin or clam shells, shrimp shells washed, dried and crushed powder → Add concentrated hydrochloric acid at a ratio of 1:10 in a sealed mixer with cooling facilities → Stir at 45°C for 3-12 hours until all the chitin is Dissolve → cool the supernatant suspension in a low-temperature container to 10-20°C → gradually add 5N NaOH to pH 3.0 to produce NaCl precipitation, while the soluble oligosaccharide amine is in the supernatant → filter to remove the salt (salt can be recovered for industrial use Salt) → oligosaccharide amine solution dehydration and drying is the finished product → powder dry storage.

[0081] For example, 0.2g of chitin (Sigma) is degraded overnight with hydrochloric acid, adjusted to pH 3-4 with 5N NaOH, filtered, desalted, dehydrated and dried to prepare a 10mg / ml oligosaccharide water-soluble mother liquor, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com